Just before 2020 arrived, we were able to get the answers to a number of mountain bike related questions with the help of ENVE Composites. Now, ENVE is back. But this time the focus is squarely on gravel and road. With gravel races and events gaining popularity at an impressive rate, it seems like more and more riders are curious about what actually makes a gravel bike, and how premium components from brands like ENVE can make for a better ride. Also, make sure to read to the bottom to find out how you can still win an entry into this year’s Dirty Kanza race plus ENVE wheels and a gravel handlebar!

Like mountain bikes, it seems like gravel rims are getting wider and wider. Is there a rim width that is most ideal for gravel? – Luke

ENVE: This really depends on what tire size you’re running. One thing to consider is that as you add width, you add weight, so for ENVE we are always trying to strike just the right balance to make the best rim possible. In other words, as light, durable, and best riding as possible. Our G Series G23 (23mm internal width) is a 700c wheel and intended for primary use with a 38-42mm tire. Our G27 (27mm internal width) is a 650b wheel and primarily intended for use with a 1.9-2.1” tire. We could’ve gone wider on both these rims, but felt these widths maximized the rim’s design objectives allowing each model to be very lightweight and comfortable while providing ample tire support.

It seems to be an industry wide agreement that gravel specific wheels (rims) should be quite shallow. As the American gravel scene seems to be the main motor in gravel R&D, with popular events like DK and others, why have the industry and ENVE in particular, decided that the aero benefit of a taller rim + a well-fitting tire, is less important on gravel, even when the ride is 200km + long?

Would love to hear your thoughts on this, both for your own company and others. Shout out from Norway! -JD

ENVE: Sure, and a great question. ENVE has been looking at this for many years at this point and we asked ourselves the question of “aerodynamics in gravel” back in 2014 in the development leading up to the launch of the SES AR Series of wheels. What we learned is that basically once the tire exceeds 32mm and gains any side knobs/tread, you lose the majority of aerodynamic benefits. To make an aero rim for a larger tire is possible but it starts to get crazy wide and therefore exceedingly heavy, and again, this is assuming there is little to no tread on your tire.

In short, the value proposition just isn’t there. On top of that, there is the fact that gravel riding is often on rough roads, if you’ve ridden or talked to anyone who’s raced DK, you know that the race is rough and also pretty slow. On a long, rough course like DK, a shallow rim with a refined laminate like the ENVE G23 provides unprecedented compliance and therefore comfort which is so valuable. Also, most gravel rides and races include a lot of climbing. DK is over 11K feet. Again, lightweight trumps aerodynamics at the speeds most are climbing gravel roads at.

With all the research behind aerodynamics with road wheels and road tires leading to the 1.05 rule of thumb between the tire and rim width, how does this apply to gravel tires? Will we one day be running 45mm wide rims at Kanza? What research has been done on gravel bike aerodynamics? With 10 hours spent at 20mph a very slight difference in aero drag can make a huge difference in finishing time. – Michael

ENVE: We won’t pretend to have all the answers here, but what we do know and have learned is:

- Knobs and tread make it nearly impossible for air to transition smoothly from tire to rim, and therefore, aero efficiencies are essentially nullified by tread.

- The longer you spend on a bike, the more important light weight and comfort are. This is what we’ve developed the G Series to achieve. We made the rims as comfortable and compliant as possible to reduce rider fatigue. We made them as light as possible for the obvious reasons and that most gravel races include substantial elevation gains.

- Most riders are not averaging speeds of 20mph racing/riding gravel. Few average over 15mph, and most are in the 10-13 mph range. If you are a top fuel 20mph kind of guy, and the course is relatively smooth, we’d recommend something like our 3.4AR w/ a 30-33mm tire. This will provide some aero advantages, but only if you’re willing to say goodbye to tread or keep it to an absolute minimum. Colin Strickland won DK running our 3.4AR…

- Oh, and to actually answer the question. We don’t foresee 45mm wide rims at DK anytime soon.

You have been making rims wider and wider and tires became fatter and fatter. Despite better tire integration, the first one has been proven to ultimately be less aerodynamic (larger frontal area) than less extreme rims and the second one showed that except being able to use lower minimum pressures and a bit better grip, they were not bringing more absolute performance (to keep same comfort, wider tires need lower pressures and RR ultimately remain the same)… why are you pushing those 30+mm rim widths from an engineering point of view? – Jordi

ENVE: Hopefully we understand your question well enough, but it sounds like what you’re asking is “Why if 30mm isn’t more aero, and if large volume tires aren’t higher performance, then why do it? For ENVE, we engineer our SES lineup of wheels for holistic performance. Yes, an SES AR wheelset w/ a 28-30mm tire is going to have more frontal drag than a standard SES wheelset with a 24-26mm tire. What we achieve with the AR series is first, greater aero stability. A 4.5AR w/ a 28mm tire is extremely stable in crosswinds and at yaw. Also, there is rolling resistance. The rougher and more imperfect the surface, the more a high volume tire plays into your favor. On a rough road, the gains achieved in rolling resistance, will outweigh the losses caused in aerodynamic drag from an increased frontal area. It is also worth noting that these gains are further pronounced at slower speeds.

Given that most roads people ride aren’t perfectly smooth, these same people are simply realizing that 28mm tires are more fun/enjoyable to ride than 25mm tires. We say, if you’re going to ride a large volume tire anyway, you might as well have the option to have a high performance aero system. This concept was originally born from testing with our World Tour team at Paris-Roubaix. PR is a perfect example where you have to run a 28-30mm tire to survive the cobbles, but the majority of the race is on smooth pavement. Well, making a rim aerodynamically optimized for use with those tires was a substantial efficiency gain over running the same tire on a more traditional width aero rim. The width of the rim is simply determined by the width of the tire we are optimizing around, and the goal being to make the system as aero as possible.

If you’re a light-weight racer looking for maximum efficiency, you should still only be looking at our SES (Non-AR) wheelsets, and running 25mm tires. If you’re not racing in traditional road events, and looking for aero performance, more confident handling, comfort, and fun – then SES AR with a 28-32mm tire is going to be the ticket.

You developed a wide range of rims but it seems like little work has been done on spokes. We see carbon spokes on Cadex (Giant) and from Farsports, after Mavic did several attempts. Isn’t it a major possible improvement to bring back stiffness on rear wheels? – Jordi

ENVE: This is a great question. In short, carbon spokes have been on our radar from day 1. We’ve seen the pros and cons of various designs, ridden and tested most of them and are now beginning to understand if there is a real performance gain to be had. Additionally, there are materials other than carbon that we have been investigating. Stay tuned.

When or if are you going to adopt the proposed and/or new ETRTO/ISO tubeless rim standards for road bike rims? -Lawrence

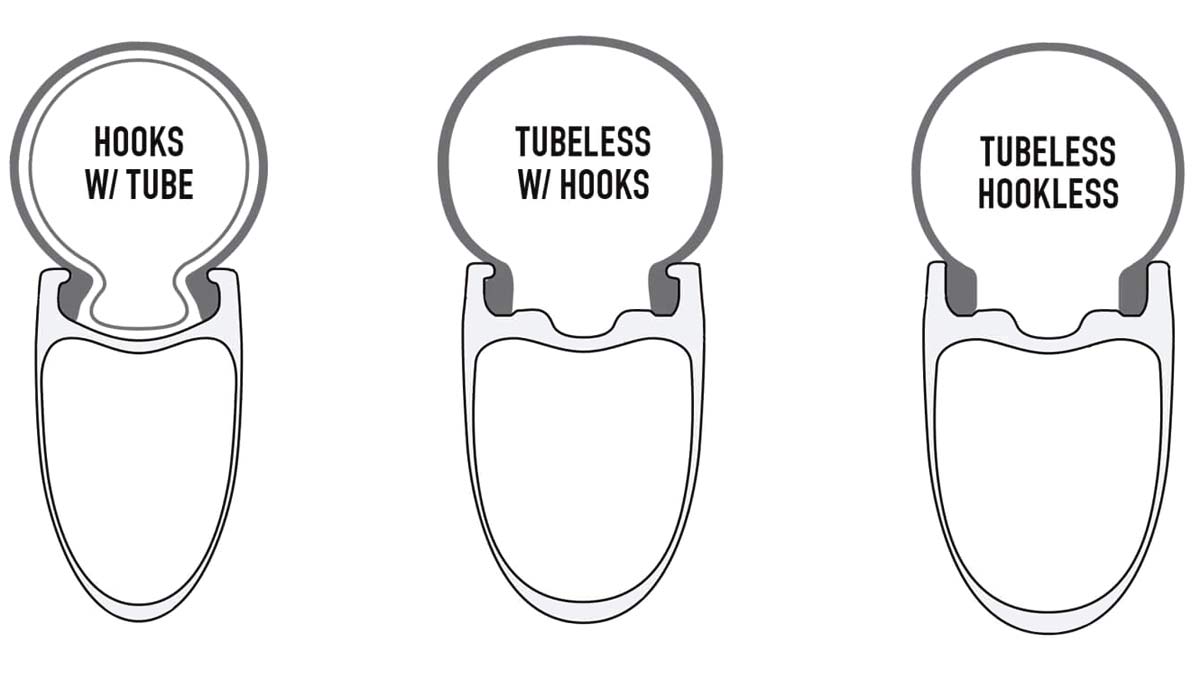

ENVE: Thanks for your question Lawrence. There is certainly a constant push in the bicycle industry specifically as it relates to wheels, for balance between the adherence to existing standards and being able to develop new product with real world advantages. Since ENVE’s first tubeless product offering in 2009 with the XC and AM mountain wheels, and continuing until the present, ENVE has always used the ETRTO standard as the basis for the design. This includes using the provided dimensional ranges in the design.

Over the past decade, improvements in tooling, molding, layup, finishing, quality control, and other manufacturing processes has allowed us to target more precisely where in the standard range we fall to improve product performance. An example of this is the bead seat diameter (BSD) dimension. The ETRTO requirement for this dimension has been 621.5+/-0.5mm. Early ENVE tubeless products had a range of 0.75mm from rim to rim, which used most of the provided tolerance band. Due to the aforementioned improvements, current product offerings have a reduced range of variation that is less than 0.2mm. This in large can be attributed to the introduction of straight sidewall rims which benefit from machined hard molding vs. soft molds that can be extracted from between the bead hooks of a crochet type rim. This improvement results in a consistent, more user friendly tubeless setups.

When you look at the ETRTO standards as they relate to rim and tire compatibility, most modern wheels do not strictly adhere to this standard which states that a crochet style rim when paired with a 28mm tire can have an internal width no greater than 19mm, while a straight sided hookless rim can be no wider than 20mm. There are many rims on the market today that are wider than 20mm because going wider delivers better performance. So what does this mean to ENVE as a wheel manufacturer? Well, we have to do a lot of testing.

A tire manufacturer is only required to pass their tire on a rim that is 19mm wide and therefore, the onus is put on ENVE to ensure the safety and compatibility of rims that fall outside the recommendation of the current ETRTO standard. For this reason we test extensively to ensure that our customers are running tires that are safe and designed to the demands of modern tubeless optimized aero road wheels.

However, we are not doing this testing in isolation. We are working closely with tire manufacturers to share test data between rims and tires so we can all produce compatible and safe product. To date we have a few examples of tires that formerly were not compatible with our hookless rims, and since we’ve been working together, changes have been made to tires in question and these tires are now safe to run with a hookless ENVE rim.

As far as the new standard is involved, we have been involved from the beginning and in many ways driving the proposed changes. The new standard does open up the opportunity for future development possibilities with wider rims and tires. The new standard is also better at defining how rim and tire dimensions are to be measured. For example, the old standard doesn’t explicitly consider the added thickness of tubeless rim tape to the rim’s BSD and the new standard requires the rim to be measured in its tubeless compatible configuration.

As for the future, we’re ready – given that our current product offering already complies with the proposed new standard.

First, do carbon wheels go out of true?

ENVE: Yes, a carbon wheel can go out of true. We can’t speak for all rim manufacturers, but an ENVE carbon rim when it comes out of the mold is perfectly flat and the rim once cured wants to stay flat forever. In other words, if your rim is out of true, it is being distorted against its will by the spoke tension. So, in order for a built wheel to go out of true, something has to be wrong with the wheel build itself.

Second, all things being equal between a carbon and aluminum rim (size, inner width, application), would you use the same spoke as an aluminum rim? Thanks, John

ENVE: Sure. There are many examples of this. It really comes down to the objectives of the wheelbuild in terms of ride characteristics, weight, and price.

Hey, I’ve got 2 questions: First: what is the difference on riding a wider rim? Any benefits for going 25-622 and not 20-622 (ETRTO) for example.

ENVE: Chris, there are a few factors to consider as they relate to rim width. In some cases, aerodynamics will dictate the width of the rim (ENVE SES AR wheelsets for example). In others, the width of the rim allows for more volume and support of a wider tire (ENVE G Series and M Series gravel and mountain wheels for example). Again, the widths of these rims are decided by tire size as well.

Ultimately, the width of the rim is a result of the design’s intent. We are always trying to strike the perfect balance of width, depth, compliance, stiffness, weight, aerodynamics, etc… If you haven’t ridden a wider rim, you should. It’s really the only way you’ll know the difference. Just remember that by increasing width, you increase volume and your tire pressure will need to come down from what you were running on a narrower rim, assuming the tire size is equal, to capitalize on the benefits of adding volume.

Second, this might be a bit rude. Since there are not a lot of factories who produce carbon rims, how do you justify your prices in comparison to other competitors? Thanks in advance, Chris

ENVE: Chris this is a fair question. We answer it all the time. Simply put, with carbon rims, you get what you pay for, both in terms of product performance and service. Many people think that ENVE costs what it does because we are manufactured in the US. While direct labor does impact the cost of an ENVE rim, this is not why ENVE are priced at a premium compared to rims manufactured elsewhere.

If you ever get the chance to visit our factory in Ogden, Ut, we’ll be able to show you, as we’ve shown many others, that it’s what happens behind the scenes that drives the price of an ENVE rim. What you’ll see when you visit is that ENVE is constantly investing in R&D, testing, customer service, etc… We prototype and test more than anyone else can because we do nearly everything related to making a carbon rim under this one roof. We aren’t simply designing a rim and decal, and placing an order with the manufacturer, we do everything here.

When you buy ENVE, you are buying the most advanced carbon rim structure available (as defined by the design’s objectives) and you become part of the ENVE family which means we want you to be happy. This of course starts with delivering a product that exceeds your expectations, and is followed by making things right if something goes wrong. Unlike many brands, when you call, you’ll talk to another person who is likely as passionate about riding bikes as you are.

What is ENVE doing to improve quality control? Are rims given any sort of scan (ultrasound, X-ray)? Batch testing? Outside of catastrophic impacts, carbon rims seem to fail where there are production flaws. – Maxwell

ENVE: Continuous improvement is one of ENVE’s core values. We’ve been making carbon rims for well over a decade now and have always placed strength, durability, and reliability as top priorities for our rim projects. QC is everyone’s responsibility at ENVE and each step in the process to making a carbon rim has numerous sign-offs and redundancies to ensure quality is met. To ensure quality in production, we perform regular testing of inline product to prevent quality issues from cropping up. The beauty of US manufacturing for ENVE is that we control all of this. Because we manufacture and test product under one roof, we maintain a very close relationship with our product. If something is identified as questionable or wrong, we can simply stop production, do inspections, make a corrective action plan, and implement it. Quality is our number one priority as a premium rim and component manufacturer.

If you’re ever in Ogden, UT feel free to stop by the factory and we can give you a tour.

Has all this talk about gravel bummed you out since you missed the chance to register for this year’s Dirty Kanza? Well, there’s still a chance. Technically 10 chances, since ENVE is giving away 10 entries to the Garmin Dirty Kanza. As an added bonus, one grand prize winner will also receive a set of ENVE G-Series wheels and handlebar along with their entry to DK to try them out! Winners can choose their DK poison with your choice of the DK200, DK100, DK50 and DK25. However, the DKXL is excluded.

To enter, follow the link below, fill out the form, and subscribe to the ENVE newsletter. The contest ends February 18th, and the winners will be notified by the 21st.