We know, there’s no such thing as a stupid question. But there are some questions you might not want to ask your local shop or riding buddies. AASQ is our weekly series where we get to the bottom of your questions – serious or otherwise. This one covers tire inserts! Hit the link at the bottom of the post to submit your own question!

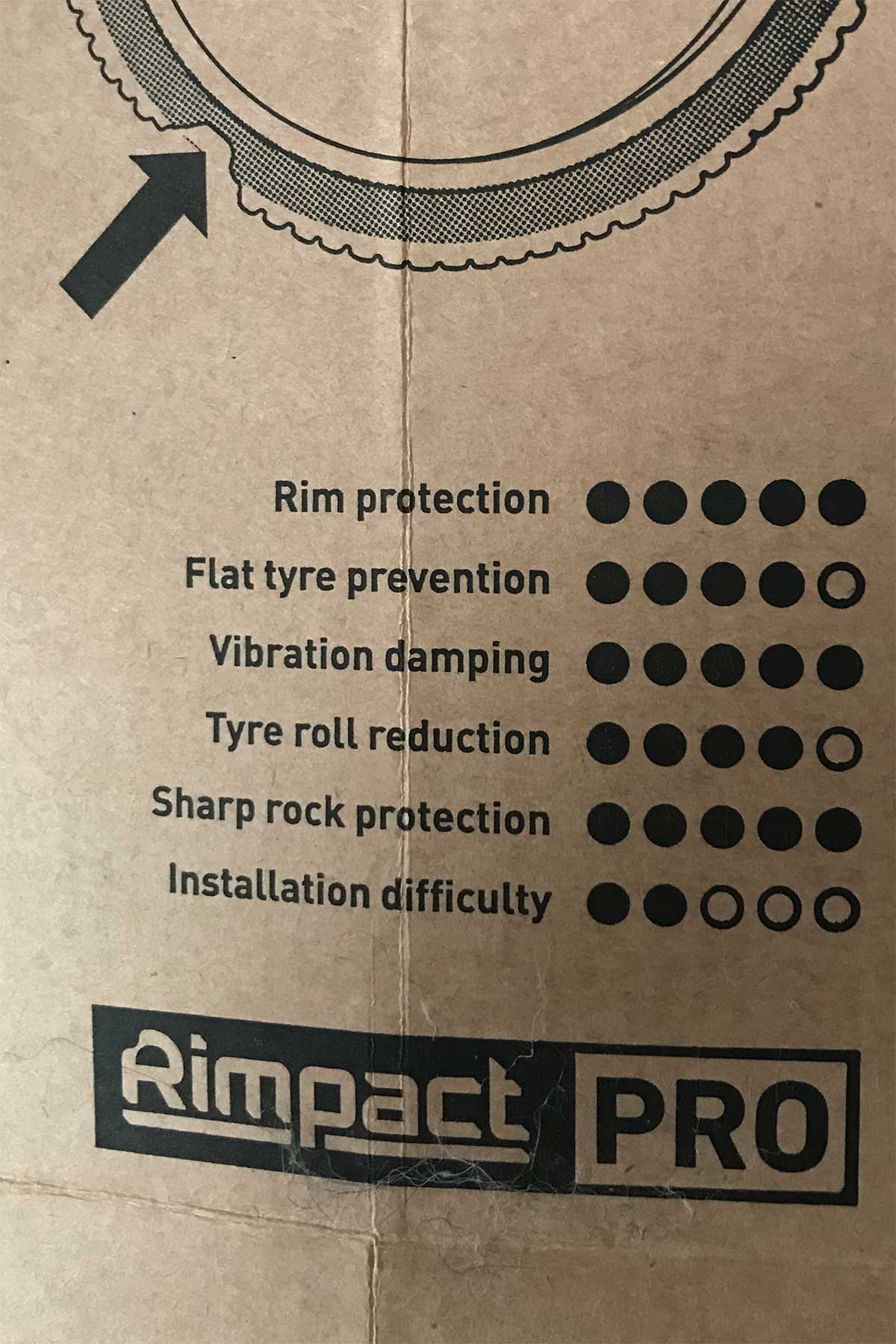

I’ve been running tire inserts on my Cannondale Jekyll enduro bike for the last month or so. I have a Rimpact original in the front tire and the Rimpact PRO in the rear. To say I’m pleased with the upgrade would be a crying shame of an understatement. I won’t go into it in full detail here as a long-term review is brewing, but what I will say is this: rim protection and pinch-flat prevention aside, the ride feel improvement is tangible.

I’m wondering why on earth I never considered a set before now, having written off both alloy and carbon rims in the last six months. Anyway, tire inserts are a thing. If you’re riding fast, rocky terrain, it’s not a question of should you run tire inserts, it’s a question of which ones you should run.

There are now heaps of tire inserts on the market, all claiming to offer at least some degree of rim protection and pinch-flat protection. Others go further claiming to offer improved traction and handling, vibration damping and thus, reduced rider fatigue.

We took a bunch of “stupid questions” around tire insert tech and put them to the brand experts, picking their brains on all the important things you need to know when considering purchasing a set. Thank you to Dan at CushCore, Matt at Rimpact, Rob Sherratt at Nukeproof, Luis Garcia at Ride Panzer and Ken Avery at Vittoria for contributing to this week’s Ask A Stupid Question.

What hacks would you recommend for installing a tight-fitting tire insert?

CushCore: We have an “Official” Install Video Here. However, here’s an unedited , “start-to-finish” video that’s super easy to follow, and frankly probably better.

-

- Another option here

- Our Bead Dropper tire lever is also helpful.

CushCore fits tight on the rim by design. That’s part of how they work, so don’t pre-stretch your inserts!

Insert will make the bead feel tighter, but a difficult install usually has more to do with the tire than the insert. Tire bead diameter can vary a lot, and the bead doesn’t stretch.

That said, there is a key technique that WILL help with a tight install. Drop the bead!

Side note – it really helps to support the wheel on something. A garbage can, 5-gallon bucket, etc. It’s not just for ergonomics, it allows the tire to flex around on the rim while you are working.

Once you have the insert on the rim and the wheel inside the tire (as shown in our installation videos), install enough of the tire to get some tension on the bead – about 3/4 of the tire. Once it starts to get tight, STOP. Go back to part of the bead that is already in the rim, and position the tip of your tire lever directly on the bead. Hold the lever perpendicular to the tire and use it to force the bead directly down towards the center of the rim. Continue adding pressure until you feel it slide down into the rim well (the little channel in the center). You will know when you get it because there will be a visible gap between the tire sidewall and the rim. Now continue along the installed portion of the tire, dropping the bead every few inches.

If the bead starts to pop back up out of the rim well, go back and install another small section or bead onto the rim. The bead need to stay in tension to keep it down in the rim well. Alternate as needed between dropping the bead and installing small sections until the tire is on.

For softer tires, skip the lubricant/soapy. It can make the bead walk. Lube can help with stiff tires, but don’t apply it too early! Only add lube after the bead is in tension.

One final tip for the last section of tire. It can be difficult to insert the lever under the tire when the bead is tight against the rim. You can avoid the problem by inserting two levers side by side for the final two bites.

Our new “Bead Dropper” tire lever is designed specifically to make it dropping the bead easier.

Rimpact: We have found that the overwhelming majority of our customers don’t really struggle to fit the tire inserts. This leads us to believe that if you use good tire fitting techniques where you don’t rush any of the steps, the inserts should be installed without hassle.

That said, if we were pressed to point out a particular part of the installation that is crucial, i’d say it’s the ‘Pinch and Roll’ technique. When the tire is almost fitted, the insert is installed and the very last 6-10 inches of bead needs to be seated to complete the install.

Here, most people fail to ensure the tire is sat on the rim correctly. They crack out their tire levers and proceed to snap them, losing faith and damaging their tires/rims. The fitted portion of the bead needs to be in the center of the rim, underneath the insert and not up high on the outer part of the rim, causing the tire to be tighter.

This is why people find Tire Inserts harder to fit, because the Insert sits where the bead is and stops if from naturally falling into the centre of the rim. We’ve seen it time and time again, where people swear they have ensured this, only to find they could have gained loads more by being more aggressive with the tire in this step.

To ensure the tire is fully unseated, grab it with both hands, pinch the sidewalls to squeeze the bead under the Insert and roll the tire back towards you whilst trying to tuck the bead in under the Insert (the same motion as revving a motorbike grip).

This will allow the bead to sit in the narrowest part of the rim relative to the hub and release tension on the unfitted portion of the tire. There are pictures and a step by step instruction on our website that better illustrates this but if done properly, you may even manage to install the whole tire without tire levers. Using one or two isn’t the end of the world though.

Nukeproof: In 100% honesty I’ve not needed any hacks with our system. The Nukeproof ARD system is pretty easy to fit. I can tell you from my experience as a unqualified/non-mechanic I can fit tyres to the rim as normal with our ARD inserted.

Just ensure the tyre bead is not on the edge of the rim and work the tyre on as normal. As with any tubeless system, if you have an “Air Shot”/Tubeless style track pump, that makes life a little easier to pop the bead on the rim, but nothing major! One of the key design requirements for the Nukeproof ARD, put to our engineer, was to have a system that was easy to fit.

Panzer: The most important thing is that they are compatible in all measurements. During assembly, the most important thing is to put the insert well lodged in the rim and put the tire on little by little, pressing the tire towards the center of the rim. That is the key point to get right in order to install it easily. Many people over-force the tire without taking that step and have major complications.

In this video the most important step is between 0:32 and 0:39.

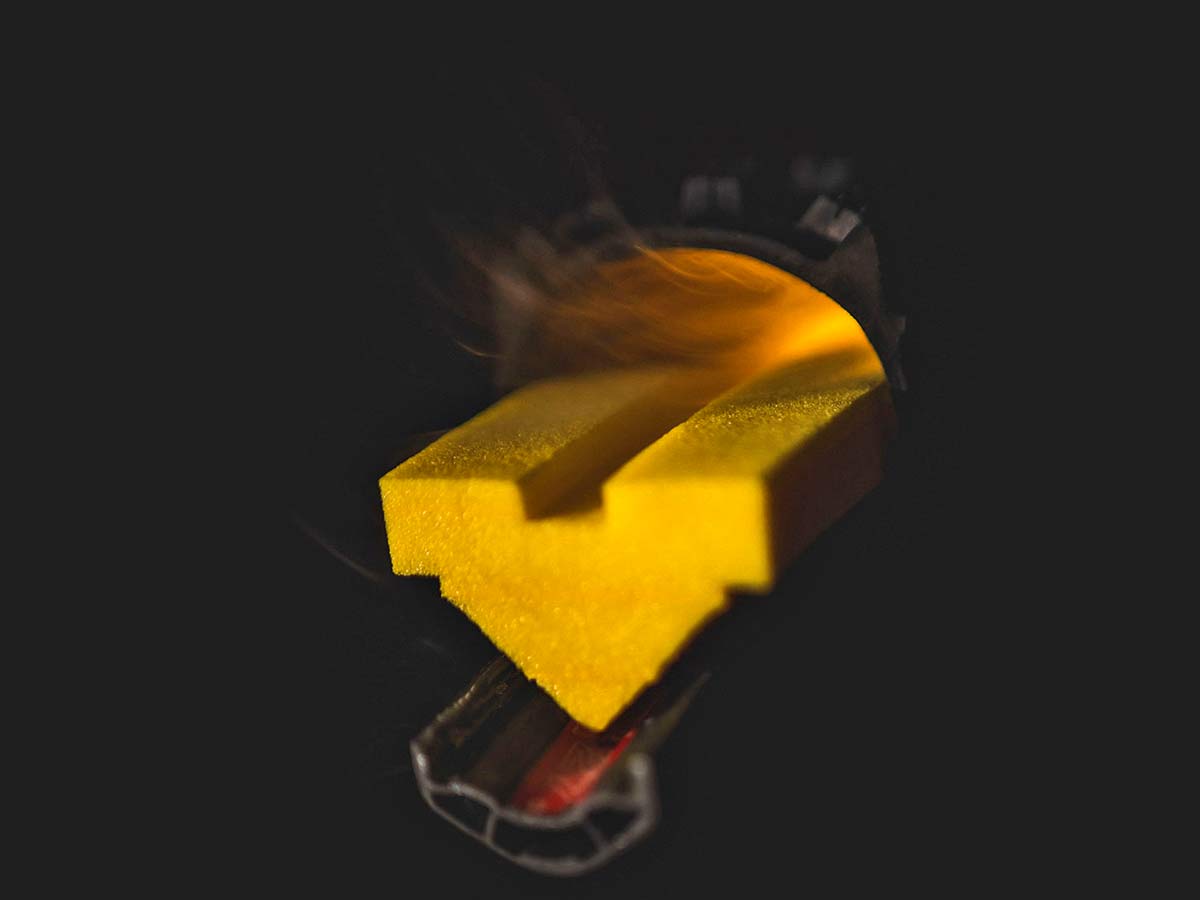

Vittoria: Even a tight Vittoria Air-Liner is not bad to install, as the groove along the belly of the liner allows you to place a rim wall there, while you work it around the rim. I actually cut my liners short, so they fit tighter, and this system still allows for easy install.

Why do riders run a light-casing tire with an insert instead of a DH-casing tire?

CushCore: Because it’s a great setup! Obviously, a lighter tire saves weight, but there is more to it. It’s a way to combine the strengths of a light casing and a DH casing, while avoiding the weaknesses of both.

CushCore does many of the things a downhill tire does, but doesn’t rely on a stiff casing. You have more freedom to run a lighter tire without the normal consequences.

A big advantage is rolling resistance. A thinner, more flexible casing, rolls faster. The stiff casing on a downhill tire saps a lot of energy, and that’s a constant penalty. People often blame the weight, but I think rolling resistance is actually the bigger factor.

A thin casing also has more supple bump response and lively feel. CushCore is designed with an air pocket under the tread to take advantage of this. The air pocket governs tire response on smaller deflections, like when you are just pedaling along, or on small bumps. The elastic quality of air is perfect in that situation. The insert has more influence on larger deflections, like sharp rocks or side loads in corners. The insert material is less springy than air, which helps manage the excess energy and keep the tire on the ground.

One thing to be aware of is that CushCore does not prevent cuts in the tire casing. If you ride in an area with sharp rocks, you may need to stick with tougher tires for cut protection.

Rimpact: When talking specifically about Enduro or All Mountain riding, some riders opt for the lighter casing with a Tire Insert because of efficiency. Doing a big day on heavy 1300+ gram DH tires is tough compared to pushing sub 1000g tires around the same route.

Our Tire Inserts weigh as little as 90g for a 27.5″ Original Insert and only 150g for a Pro Insert, so pairing this with a lighter casing allows for riders to retain the protection levels offered by the burlier casing without sacrificing on weight.

An added benefit of the Tire Insert that is often overlooked is its vibration damping qualities. This extra reduction in unwanted vibrations can lead to making the bike feel more composed and also helping the rider stay fresher on the bike for longer. This is something DH tires don’t really offer so makes the lighter tire/Insert set up even more attractive.

When considering DH riding, running a DH tire is a good idea as the weight drawbacks don’t come into play. However, it’s even more necessary to run Tire Inserts as well due to the harder hitting rougher tracks DH bikes are subjected to.

Nukeproof: The inserts are not designed to get away from using the correct casing for the intended use. If you’re running a trail tyre with an insert and racing/riding a Downhill track/ Enduro stage you’re still asking for trouble!

Tire inserts are an extra layer of protection. ARD will not 100% eliminate punctures, tyre nicks/tears, however it offers more protection and will cut down on the chance of rim damage/failure. It’s also possible to ride on the ARD to get you to a safe/convenient place to repair the tyre/puncture.

Vittoria: Yes, this is absolutely happening… I do this on my own personal bike in fact. The bead stability, and impact resistance makes such a big difference, that I can run a lighter Trail casing tire, and not have any issues.

The net weight of a Trail casing tire + Air-Liner is lighter than a 2-ply tire (by itself), and it feels more lively. That said, if you are Enduro racing, I would still recommend the Enduro (2-ply) casing, with an Air-Liner, as it’s the most bomb-proof way to go.

Do I need to use extra sealant when I run tire inserts? Do they absorb the sealant?

CushCore: Our inserts don’t and can’t absorb sealant. We recommend running the same volume of sealant you normally run without CushCore.

Rimpact: Yes, you should run more, but no our Tire Inserts do not absorb sealant. As explained in the previous question, Closed Cell foam does not absorb fluid, in fact the foam Rimpact is made from is rated with a <1% absorption specification. So why do you need extra sealant if it’s not being absorbed?

Simply put, the surface area of the inside of a tire increases when you add an Insert. Sealant tends to cling to any surface that isn’t super slick and so by upping the quantity slightly, (we recommend up to 25%), you mitigate the loss of this sealant spreading over a greater surface area and allow for enough spare to clog any spontaneous air leaks.

Nukeproof: Just set the tyre up as per normal and get out and ride.

Panzer: When we mount a completely new Panzer Evo with a new tire, there is consumption of approximately 45ml of sealant. This is because it gets deposited on the surface of the insert and the inner face of the entire tire.

So, you only have to use an extra 40ml extra in the initial assembly. For subsequent fills there is no extra consumption.

Vittoria: Vittoria Air-Liners don’t absorb sealant, so you don’t need to run extra.

How do your tire inserts differ from a bit of pipe insulation?

CushCore: There seems to be a misconception that foam is foam and it’s basically all the same. Maybe that’s because packaging and insulation foams are so common, that’s just what people think of.

“Foam” is just a generic term, like “plastic.” It covers a huge range of different materials with very different properties.

People are more familiar with plastic, though, so we know “plastic” can mean anything from the brittle material used to make cheap toys to highly engineered plastics comparable in strength to steel.

Foam is essentially plastic with a cellular structure, so the same rule applies. The properties of the foam depend on the polymer it’s made from.

Tire inserts need a high performance foam. It has to be light weight, but still be able to withstand severe impacts and abuse without falling apart. That requires a polymer that is very strong and flexible. We used closed-cell foam — open cell foam is too soft to do anything inside a tire. The “closed cells” are gas bubbles trapped in the polymer, like miniature air springs. If the cell walls break down and lose their gas charge, the foam deflates into a regular piece of plastic.

You can test this for yourself — just pinch some of that pipe insulation between your fingers and you will hear the cells pop!

Durability is very important of course, but there are lots of other considerations in getting the material right. There is a whole world to foam if you look for it. Did you know there is an International Foam Expo?

Rimpact: Density, durability, shape, fit, closed cell composition and more. Pipe lagging is many times ‘softer’ than the foam we use. This lack of density means it can’t stand up to the forces the user will put on it and thus will do nothing to protect the rim or support the tire.

So why not put solid rubber inside your tire to act as an Insert? The reason Rimpact foam isn’t just made to be ‘as dense as possible’ is due to the relationship between density and force dissipation.

Think of a coil spring that is too stiff to compress. When force is applied to the top it will pass said force through to the bottom of the spring without flexing and compressing. Due to the spring being too stiff, it does nothing to dissipate this force or slow momentum which is why we use the particular foam composition we do, to best strike this balance.

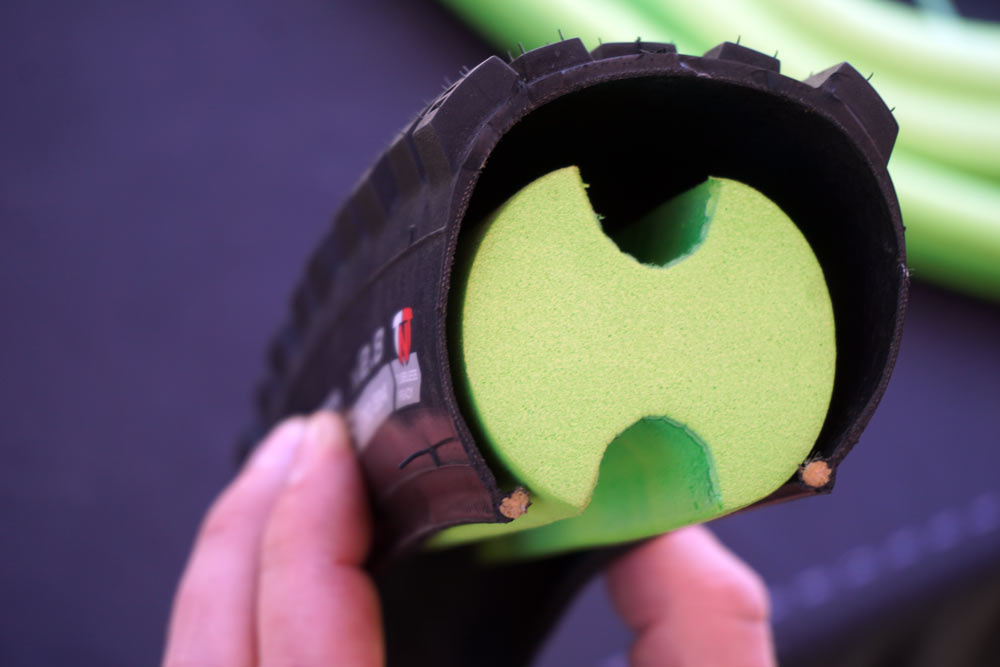

Another way in which Rimpact Tire Inserts differ greatly from pipe insulation is in profile. We carefully tested and refined different Tire Insert shapes over the last two years to ensure the Insert sat deep in the tire, supporting the bead and side walls, so that it provided as much rim protection whilst also being as light as possible.

We also bond our Inserts to form a full loop rather than use a zip tie. This means no hard components inside your tire but it also means the Insert is much higher in strength and can fit tighter to your rim. This tension will cause outward pressure on the sidewalls and ensure maximum support.

One of the big talking points around Tire Inserts, especially in their early adopter days was whether or not they absorb sealant. This was a rumor spread by DIYers that had previously used home-made pipe insulation Inserts. Pipe Insulation is made from Open Cell, Polyurethane Foam meaning each cell is open ended allowing fluid and air to pass through it.

It’s characteristics make it soft and flexible but also absorbent, like a sponge. Terrible for use inside a tire. Closed Cell, Polyethylene Foam on the other hand is made from cells that fluid cannot pass through. This makes it waterproof but also firmer as it’s cell structure is more rigid. Rimpact is made from a specifically modified Polyethylene Foam designed for impact performance.

Nukeproof: The material we use is a “closed foam” material that we have developed with our material partners to meet a list of demands. This is a special EVA “recipe” designed to give maximum density with minimum weight (in general increased density = increased weight), impact absorbency, low weight and zero sealant absorption.

We did start with a similar question, so development started from a standard pool noodle and we worked our way from there to perfect the material we needed.

Panzer: Good question! Pipe insulation is designed only to thermally insulate. It is not prepared to work under fatigue, much less to withstand impacts under air pressure in direct contact with liquids. We could comment extensively on the characteristics of the main materials used.

For these types of jobs, there are many different ones, but none are valid for the use of tire and wheel protection for an extended period of time.

Our Panzer Evo is a type of foam developed to work under air pressure and in direct contact with liquids without altering its behavior when faced with strong impacts. There is no liquid penetration to the inside, even with large cracks in the material. Only a thin layer is deposited at the surface level in the same way as it does in the tire.

It includes the insertion of 3 reinforcement sheets that increase the structural rigidity and with it, the protection and durability of the insert itself. The improvements compared to the Panzer classic are quite remarkable and the differences in compound, performance and shape with a pipe insulation are total.

Vittoria: Firstly, the material is completely different.

Vittoria Air-Liners use EVA foam, which is the same stuff found in the sole of a running shoe. It’s made to take repeated beatings, and offer a controlled rebound to its original shape. It also does not absorb sealant, which is also quite critical, as the sealant is still needed to seal small punctures.

It’s designed to sit tight against the rim (not the tire), work with any valve, and also offer a tuneable air-pocket under the tread. Pipe insulation can’t offer this.

If you try pipe insulation, it literally just compresses, and does not give you any protection or damped feel. Most pipe insulation also absorbs sealant, so it defeats the purpose.

Is the main use of a tire insert to prevent pinch flats or does it offer other advantages?

CushCore: Absolutely. Some people assume CushCore is only about protecting rims and reducing flats, but that’s not true. Protection is the foundation, since other benefits don’t matter if your tire is flat, but once we have a reliable system, the real opportunity lies in using the insert to improve ride quality.

Our core performance claims are reduced shock and vibration, improved cornering, increased traction, and reduced rolling resistance. All of these claims are quantified and supported by extensive testing in-house and by independent labs.

Here’s one example. Our website claims CushCore provides a “12% Smoother Ride.” That number is based on field tests conducted by MotionIQ, a data acquisition equipment manufacturer. They fit sensor packages on mountain bikes and gathered riding data with and without CushCore. They mounted accelerometers on the head tubes to measure shock and vibration as experienced by the rider at the handlebar. When they compared the test groups, they found that CushCore reduced the impact accelerations (“G-force”) by 12%. That is a massive improvement any rider would appreciate.

That same test also found the suspension forks used 16% less travel with CushCore fitted. The insert dissipates impact energy more effectively than air alone. It also controls tire rebound following an impact. This helps isolate bump forces at the tire so less is transmitted through to the suspension.

Details about the testing behind the other performance claims are published on our website.

Rimpact: When we set out to make a Tire Insert, rim protection was everything. After testing the very first prototype it quickly became the third most important attribute after damping and side wall support.

I remember descending on them for the first time and being blown away by how much calmer and composed the bike felt. It was like I could steam through a rock garden and just pinpoint a line and hit it perfectly, then switch between lines without issue.

As I experimented with lower pressures the sidewall support meant that I could change direction quicker, load up the tire and change direction again without the wallowing and cumbersome rebound I had become used to over the years.

Since then the Tire Insert has evolved many times but has always been about the best balance between side wall support, vibration damping, rim/puncture protection, weight and price. I will never go back to riding without Tire Inserts full time.

Once in a while I ride without them in for a refresher and struggle to ride with the confidence and accuracy that I am now used to. Not to mention, the only wheel I’ve blown up and punctured since Rimpact went to market has been when not running them or when testing a failed prototype design. All bikes should ship tubeless with a Tire Insert installed in my biased opinion.

Nukeproof: As mentioned earlier, there is an element of protection from punctures as the tyre will not pinch on the rim, but the main advantage to us is that it protects the rim of the wheel. Rebuilding a wheel or using new wheel is expensive. Extra consumables can ruin any holiday/trip/ride/race!

At an elite level, in races like the EWS your rims are sticker marked at the start of the race, so you have to finish the race on the same rims you started or get major time penalties. So any protection to minimize risk/damage is key.

Panzer: Really, if you ride at very high pressures you don’t need any type of insert. But that is not positive for anyone who wants to have grip and traction on the bike, both to go down and pedal up on loose terrain.

When you discover what it means to roll at medium / low pressures – that is when you realize that you need a Panzer, hence the importance of the first question you asked me about the use of semi-solid foam-filled tires.

The importance of free deformation of the tire is vital to obtaining positive sensations in the control of the bicycle.

Therefore, the most important thing is that it allows you to roll at low pressures avoiding most of the punctures and possible rim impacts. You can have these benefits without increasing the weight of the entire wheel by more than 90g for enduro and DH and 60g for XC.

Vittoria: Yes… to both. I’ve ridden lift runs with XC tires, and done 100 mile Gravel races using liners. The protection is the first thing you notice, but the ride feel is actually most important.

You can run lower pressures, so your tires feel more supple and grippy, as well as more comfortable. Also, the damping sensation is very noticeable, as the liner takes up air-space inside the tire, so the tire rebounds less abruptly.

While this may have originated in Enduro and DH, I actually think the other benefits I mentioned are more important in Trail/XC and even Gravel applications. I literally won’t ride off-road without liners, they make that big a difference.

Have you tested your inserts with lots of different tire sealants? What sealant is best?

CushCore: We have tested with every sealant on the market, or at least all those we are aware of, and none react with CushCore. The material is highly nonreactive — most adhesives won’t even stick to it.

We use Stan’s sealant in house, but sealant is like tires in that there is no one “best” choice for every rider. It depends on your local climate, how frequently you refresh the sealant, and how large a hole you expect the sealant to plug.

Rimpact: We’ve tested the Insert for compatibility with all the major players on the market. Rimpact is compatible with all of them. As for which is best, we really rate the tried and true, Stan’s sealant.

Nukeproof: In short, yes, we tested tubeless set ups with A LOT of sealants. Whilst most brands’ sealant work OK, it’s noticeable that some do work better than others. Some also are messier to fit/refit than others!

Panzer: Of course! Today we are the only brand that has developed a specific sealant for use with inserts. The sealants that are currently on the market are problematic when working with these systems. Large solid latex particles and residues of sealant are generated in a very short space of time.

In many cases the sealant itself breaks down and the insert structure is altered due to the use of ammonia to increase the reaction speed of the sealants. Panzer sealant is water-based and contains polymers with very large wetting capacities.

It does not contain latex nor does it contain ammonia. It has a remarkably superior sealing capacity and durability unmatched by any sealant on the market today in moderate climates. Like all sealants, durability decreases in extremely hot conditions.

It does not create solid particles in its use with inserts and does not alter any compound, be it the insert, tire or tubeless tape. The sealing ability is super powerful. I invite you to try it.

Vittoria: We have tested the Air-Liners with all brands of sealant, and all work as expected. Of course, Vittoria Sealant is an easy choice, if you want to take the guess work out of the equation.

What’s the lifespan of your tire inserts?

Roughly one set of inserts per 2-3 sets of tires. That’s an average for “typical” riders. Just as with tires, the actual lifespan depends on the individual rider and terrain. Air pressure is also a factor – extreme low tire pressure (like 15 psi for a 175 lb rider) will accelerate wear.

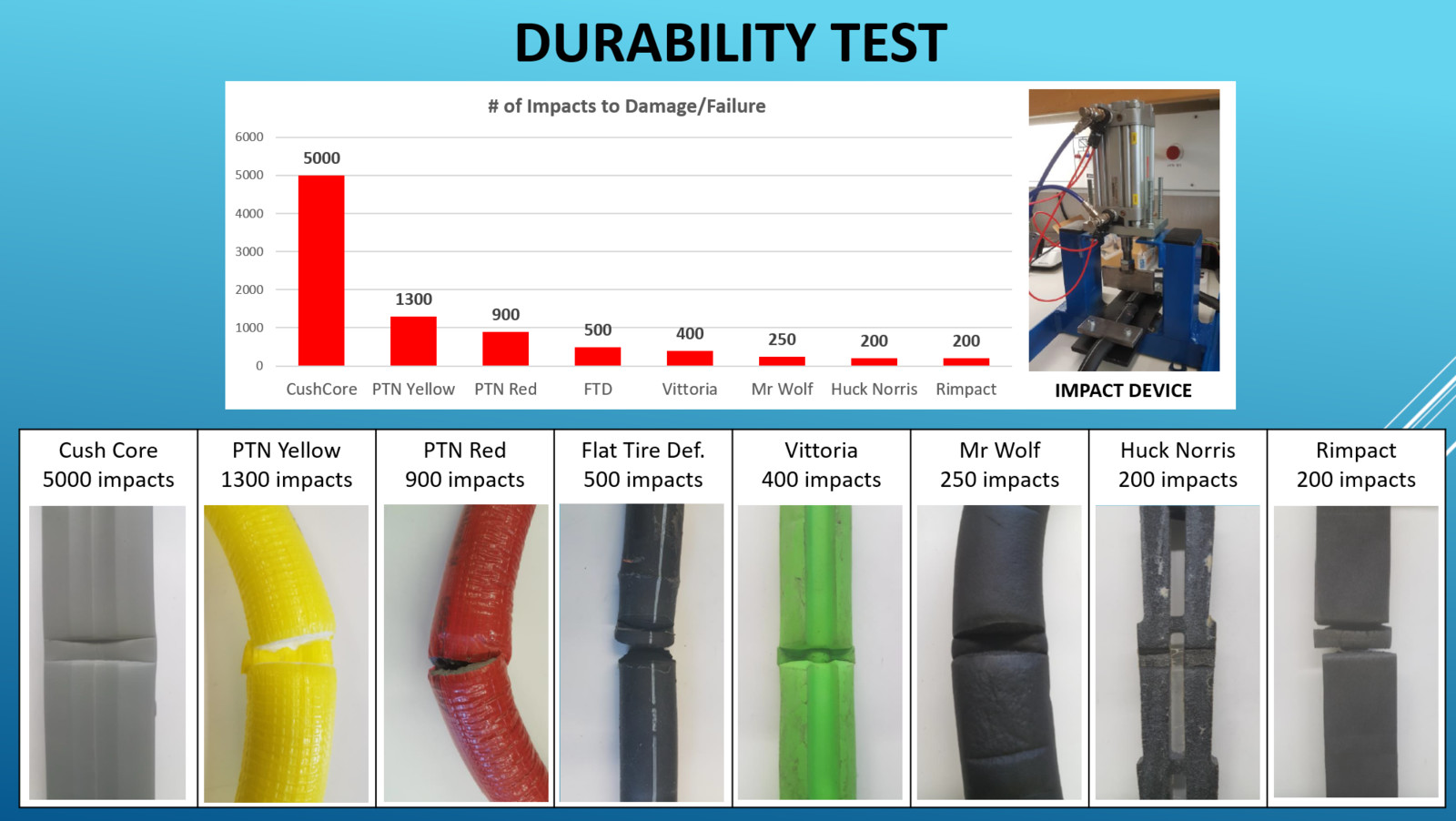

We have tested many, many types of foam, and I can say with confidence that CushCore’s material far outperforms anything else currently used to make tire inserts. For more on that, check out Wheel Energy’s test comparing eight tire inserts.

Rimpact: Like many things, this is very hard to gauge as usage cases vary drastically. The test team gets about 1-1.5 seasons out of a set of Inserts, riding up to 2 times per week and covering about 4-6km feet of descent per ride or race.

We mostly use EXO and Double Down (or brand equivalent) tires in the team and run around 17-25 psi, with riders weighing between 67kg and 85kg. However, your mileage will vary. If you weigh more, run lower pressures, ride more rocky terrain and cover more ground then you’ll get less time out of the Insert.

Inversely we’ve had messages from some of our very earliest customers who had purchased sets back in 2018 that are still riding them to this day. We offer a very relaxed one month warranty policy but if you have any issues with yours down the line please don’t hesitate to get in touch as we assess everything on a case by case basis.

Nukeproof: We don’t have a set lifespan for the inserts. They are designed to take multiple impacts and be re-usable. In testing one of our riders ran a set for a full EWS season (and practice) so that’s a fair bit of riding in some challenging conditions for wheels.

Panzer: There is a very big difference in durability for a top level rider with heavy daily use of their bike and a mid-level user who uses their bike two days a week. It also depends on the terrain for which it is used, air pressures, the type of tire, the discipline etc.

We have had clients who have used a single insert for 1.5 to 2 years, and clients and pro riders who have wrecked the insert in a single race, going down at full gas with no air in the wheel after puncturing the tire at the sidewall.

The durability of a Panzer Evo on a front wheel is very good. It lasts for years with intense use by a mid / high level rider. In a rear wheel the life of the insert is reduced. It varies between 2 years and 1 month. If you don´t descend on a flat tire at race speed then the durability is good, even with aggressive use.

I can tell you that a year has passed without us experiencing any problems using our Panzer Sealant. If you are a mid-level user with a more moderate use of the bicycle, the durability is doubled, even tripled without problems.

The same is true for wheels. There are customers who need a wheel every month and customers who use the same wheel for a whole year every day.

Vittoria: We have data that shows a 2000 hour life (of riding) per liner. In other words, that is 1000 2-hour rides, which for many people would equate to 3-5 years of ownership (maybe longer).

Why don’t we use semi-solid foam-filled tires instead of entirely separate tire inserts?

CushCore: See video above for explanation why.

Rimpact: The non-pneumatic tire (solid or semi-solid) is something that many companies and inventors have struggled with over the years in Motorsport. Finding the balance between a material density that offers the right amount of support but also the right amount of suspension is a fine line.

Too hard and the ride is harsh and grip is low. Too soft means the rim isn’t supported and rolling speed is affected. To add to this issue, the goal posts change depending on the speed/force, changing weight of the vehicle and severity of the terrain.

This is why pneumatic tires (air-filled) are prevalent. They offer adjustability. Pressures can be raised or lowered depending on the use in order to find the best performance balance available. A light rider can have comparable levels of grip vs a heavy rider by running appropriate pressures.

However, pneumatic tires are not perfect, especially in performance applications such as cycling. In our world we often lower the pressure in our tires to gain as much traction as available, allowing the tire to conform to the terrain and grip the dirt.

The problem with this approach is finding a pressure where the tire grips to a particularly slow section of trail littered with wet roots but also doesn’t wallow or roll during a faster sections of hard packed berms.

Without Tire Inserts, the user has to compromise between traction and stability but with an intelligently designed Tire Insert this is not the case. Rimpact Inserts allow for lower pressures by adding stability at the sidewall of the tire, changing the rate at which the air pressure increases and also acting as a bump stop to mitigate punctures.

The reason Rimpact doesn’t fill the entire tire is because it can supply all of these benefits without interfering with the slow speed deformation of the carcass meaning the Insert doesn’t make you ‘ping’ off of roots, rocks and other trail features. The tire is allowed to act as it was designed but with added benefits when you push harder.

Nukeproof: Sounds very heavy to me!

Panzer: The air inside the tire is of vital importance, without it, we would not be able to change the pressure and obtain that crucial change in operation that we achieve using different pressures.

If we were to use a foam compound to completely fill the inside of the tire, we would several versions of different densities. With each of them we would obtain a different behavior and sensation on the bike.

Apart from needing a considerable amount of varying densities for the same tire, there would also be the problem of degradation with use. Over a short period of time the filling gradually loses firmness and no longer performs as it did initially, making it impossible to achieve the point of firmness that we want every time we use the bicycle. This problem is already seen with mousse for enduro motorbikes.

In summary, our tire insert allows us to:

- Adapt the hardness of the tire instantly based on the type of tracks or circuits, rider weight, and track conditions

- Degradation of our tire insert does not affect air pressure, so the bike will always behave in the same way regardless of the degradation of the insert

- The Panzer EVO for enduro and DH riding weighs 90g for a 29” wheel; that’s a quarter the weight of the filling that would be needed for a semi-solid foam filled tire which weighs more than 350g

Vittoria: Pneumatic tires have always been effective due to their ability to provide cushion, low rolling resistance, and pressure adjustability… which all leads to grip on a mountain bike tire.

A separate insert is the perfect solution to maintain all of these positive traits, but add further impact resistance and bead stability. If it was molded as a single unit, the waste of a worn tire, production cost, and complexity would all be huge.

Got a question of your own? Click here to use the AASQ form to submit questions on any cycling-related topic of your choice, and we’ll get the experts to answer them for you!