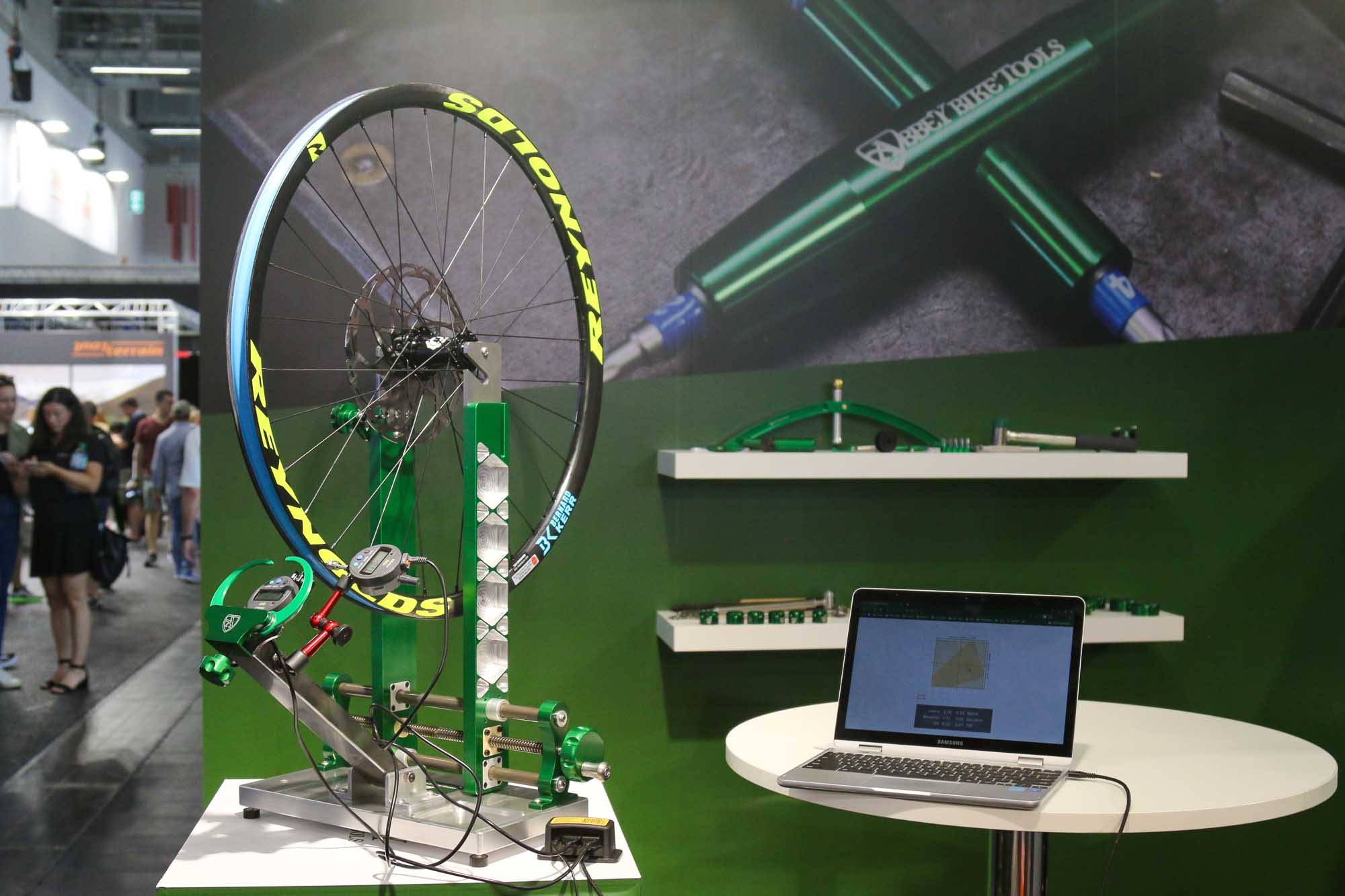

The newest tool from Abbey is here, and it’s a big one. After years of obsessing over the details about what would make the ideal truing stand, Abbey Bike Tools is finally releasing it into the wild.

The Truing Stand as Abbey puts it, is more than just a device to hold the wheel while you turn the nipples. Built from the ground up to allow for obsessively precise wheel building, the design is perfectly mirrored from side to side so you can build a wheel with perfect dish regardless of hub or rim width.

Built with a substantial machined aluminum base plate, Abbey founder Jason Quade tells us that from the beginning, they wanted the foundation of the tool to be included – not some DIY option that was added after the fact. The 6061 aluminum base is an inch thick, and includes four adjustable feet that can be used to perfectly level the truing stand.

The arms are machined from aluminum as well and will accept thru axle hubs without the need for adapters. The truing stand will still accept standard QR hubs and bolt-on hubs with axles up to 14mm, but thru axle hubs can use the integrated cones eliminating the step of placing an adapter in the hub end caps. The cones will work with thru-axles up to 25mm as well, so even your old Maverick hubs will fit. It will also fit hubs from 70mm to 220mm in width, so even those who build fat bike wheels will be set.

And in the case that you have some crazy hub that doesn’t work with the existing stainless steel plates, Abbey can custom machine additional plates based on the need.

The dropout plate also features an insert for truing disc brake rotors from 140-220mm in diameter. Since the truing arms are mirrored from side to side, you could also swap the arms around if you wanted the brake truing indicator on the other side, and on the back of the arm.

At first, the indicator arms may look similar to the typical truing stand, but that ends when you view it from the back. Not only do the indicator arms ride on sealed bearings, but they are a push-pull design which makes it ridiculously fast to move through the adjustment range. The knob is so smooth and balanced, that you can give it a spin, and it will spin for another few rotations. Coupled with the fact that you can move the main arm that the indicator is mounted to without any sort of knob or dial, The Abbey Truing Stand should save professional wheel builders a good amount of time over the long run.

The vertical arms use a linear rail system for incredibly smooth movement, which is helped by an Igus Drive bushing for the main lead screw. Abbey found that a different solution worked better for the pillow blocks, but the whole system is designed to run dry – no need for any lube or oil that will collect dust in the shop.

When it comes to using the indicators themselves, they will fit rims 15-65mm wide, and tires somewhere in the 2.6-2.8″ range (the production indicator arms aren’t finished). The green 3D printed arms will be metal for production, and are not capable of being used individually, but if you want to use just one indicator, or need to work on rims wider than 65mm, you can use the single dial indicators on the red multi-adjustment arms to measure just one side of the rim. That same indicator can also be used to measure vertical runout – either below, or even on top of the rim in the casse that the tire is still mounted.

The truing stand will be sold in different configurations, one with a single ‘feeler guage’ type radial indcator, with either mechanical or digital Mitutoyo indicators, or with the Islandix digital system.

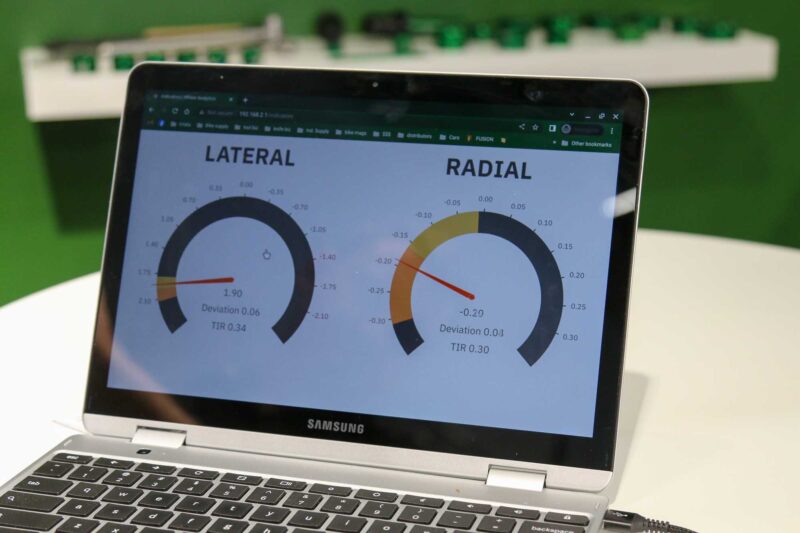

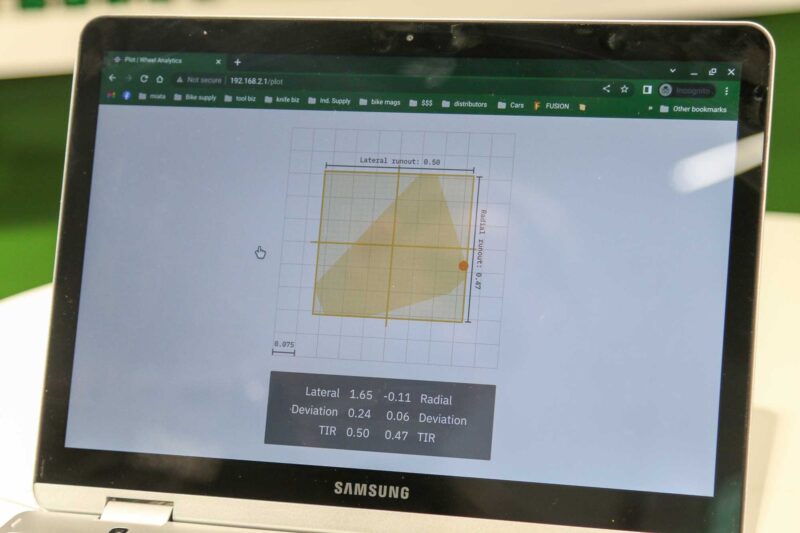

Abbey decided to work with Islandix to offer the system as an option after demoing the system themselves. Essentially a real-time digital output of vertical and horizontal runout, the system connects digital sensors to your computer or connected device so you can see a visual representation of the wheel build. There’s also a spoke tension component that can be added aftermarket, making it an impressive way to build insanely precise wheels. It also will run $2,350 for the full setup.

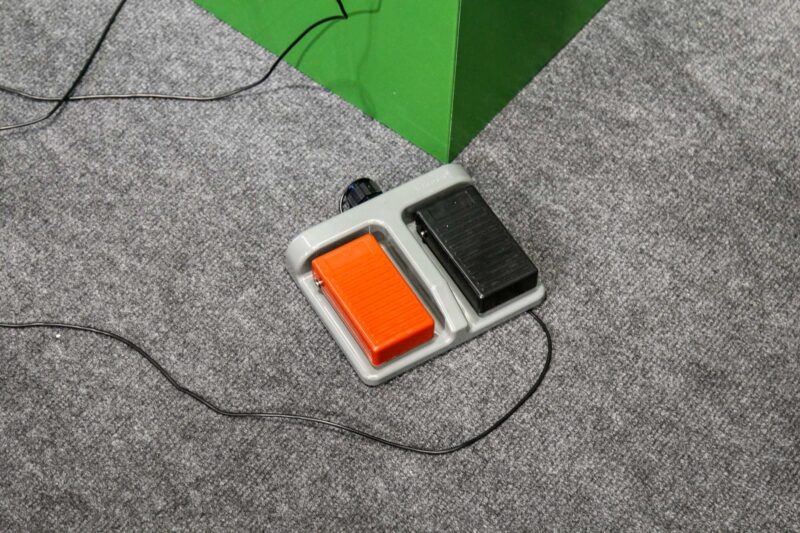

The kit also includes a foot pedal to work the system while you’re truing so you don’t have to take your hands off the spokes.

Abbey plans to sell the truing stand in batches, and is taking pre-orders for the first batch now. They expect to have only single digits of exess stock from each batch, so if you really want one, you should get in on the pre-order. Pricing starts at $1,450, and all models include a customized name plate – whether that’s your name, or a character from your favorite movie…

Pre-orders placed now should ship in September, with Abbey planning on deciding the size of the first run around July 9.