Looking for a truly custom bike? With the RM3, Argonaut Cycles is offering something truly unique with a carbon construction not seen on the small scale needed to produce one-off carbon bicycles. That’s precisely why their new carbon process is patent-pending, and how you could end up with a custom-built carbon bicycle that’s designed, built, and tested right here in the USA.

As Argonaut points out on their tech page, high quality carbon manufacturing is all about compression, eliminating air bubbles/voids, and controlling the orientation of the carbon fibers. For Argonaut, one of the best ways to handle all those variables is with an existing carbon molding technology, trapped rubber molding. This uses a rubber or silicone mandrel inside the carbon plies which are inside of the mold. When heated, the mandrel expands, perfectly squeezing the carbon between it and the mold. Only, traditional trapped rubber molding doesn’t work all that well on a small scale for custom frames. That’s where Argonaut’s patent-pending process comes in.

Thanks to the advent of 3D printers, Argonaut is able to print their own silicone bladder molds to custom form them for any desired geometry. Once the molds are printed, liquid silicone is injected inside to create the bladder.

Those bladders are then meticulously wrapped in carbon plies that have been precisely cut by their Autometrix Plotter. That all goes into a fully sealed mold which “keeps the resin from being squeezed out of the part and pressurizes the entire system, creating a 100% void free finished part. Because the plies are laid on a mandrel mirroring the final internal shape, there is zero fiber distortion.”

Not only is the silicone bladder creation unique, but Argonaut goes as far as cutting their (your?) own custom frame tooling for custom geometries. The metal molds are even CNC machined with the customer’s name on the outside. By using a lugged construction, Argonaut is able to fine tune the angles of the lugs, and then connect those with tubing to create a custom ride.

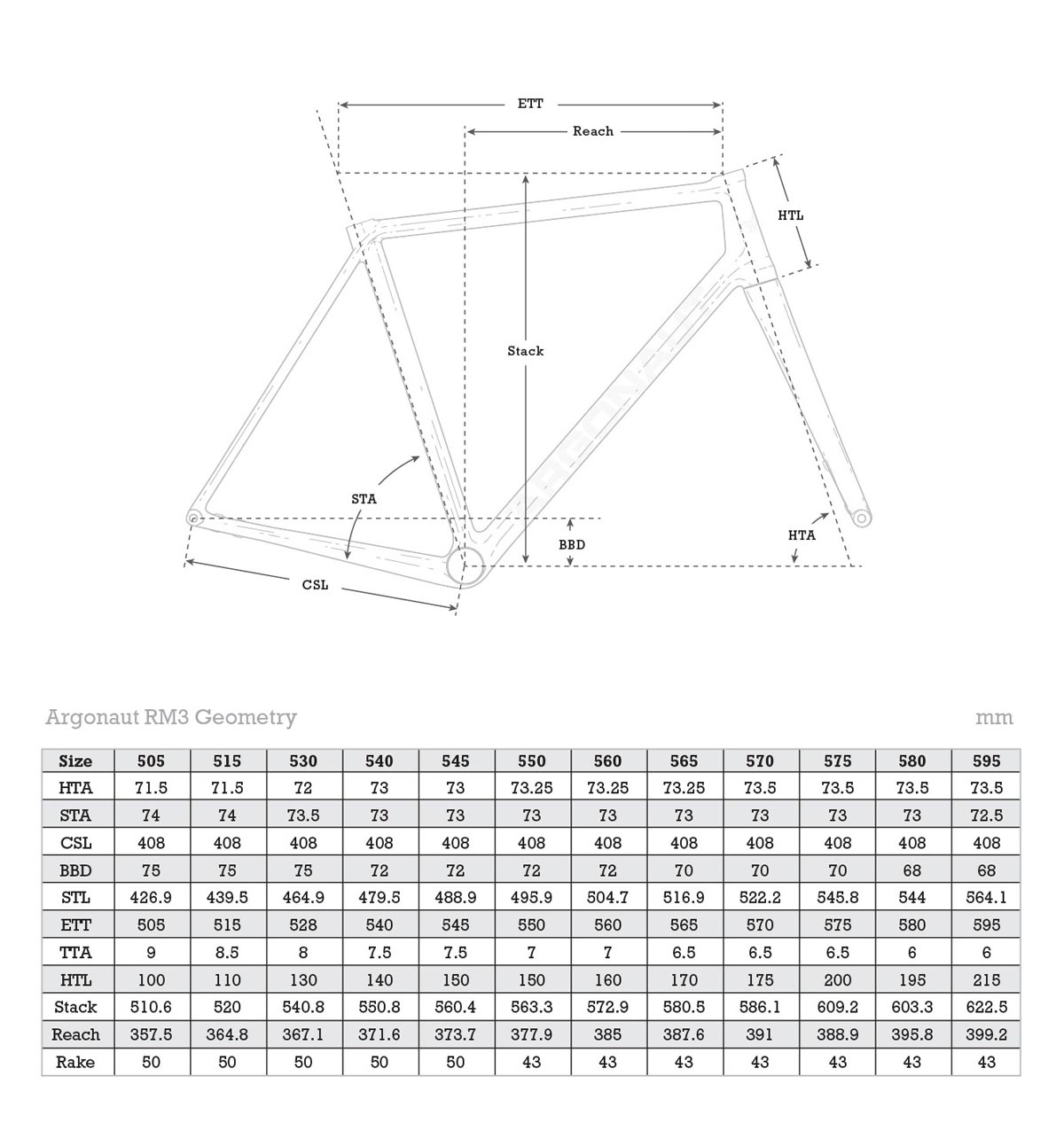

Keep in mind that even if you don’t opt for custom geometry and use one of their 12 pre-designed geometries, you’re still getting a custom bike. How’s that? Each bike includes a custom tailored carbon layup based on your size, power, and riding style.

Then there’s the new stem and fork. Not happy with creating a custom, made in the USA frame only to slap a pre-built fork on the front, Argonaut came up with a unique fork and stem for the RM3. Using the same molding technology as the frame, the fork and stem claim to be lighter than industry leading options. The fork uses standard 1.25″ lower and 1.125″ upper integrated headset bearings, and runs internal cable routing with a built-in top cap for the stem.

When built with something like SRAM eTap AXS, the front end is very tidy with brake hoses just poking out of the tape before entering into the stem. Stems will be offered from 90-120mm lengths and in -7º, -3.5º, 0º, and +6º angles.

Keeping the seatpost in place is an integrated binder, with the bolt located just behind the post.

Offered only in disc brake builds with 12 x 100 and 12 x 142mm thru axles, a threaded T47 bottom bracket, and integrated IS41/IS47 headset, the frame weights start at just 750g. Add in a 370g fork and 135g 120mm stem, and you’re looking at the possibility of some very light weight builds. Did we mention there’s also clearance for a 35mm tire?

Clearly, the most custom carbon bike can’t come cheap, but you’re also getting one hell of a build for your money. Pre-designed geometry framesets start at $6,000, with complete builds start at $11,600. If you want custom geometry too, then the price will increase. Custom geometry frames start at $7,500 with complete builds starting at $13,100, and there is also an option for custom paint starting at $600. As shown above, the SRAM Red eTap AXS build with ENVE sES 3.4 AR wheels checks in at $14,110 with a 15.1lb complete weight.

Bikes are able to be ordered now, with shipping dates selected by the buyer at first come, first served basis. Basically, Argonaut offers you the ability to choose your delivery date with a $3,500 deposit on a calendar, which are bi-monthly on Fridays. As orders are placed, those dates disappear, but it gives you a clear picture of when you can expect your new bike. Currently, the first delivery date is June 12th. That’s less than two weeks away, pretty impressive for a custom carbon bicycle!