As more bicycle brands switch to the new-ish T47 bottom bracket standard, which means that bottom bracket companies are busy coming up with the right solutions to run specific cranksets. C-Bear has been working on their T47 range for around two years now, and they just recently added a new option that should make Campagnolo fans happy.

New to their extensive collection is the external T47 bottom bracket for Campagnolo. That seems to include options for both the 25mm spindle Ultra Torque cranksets (T47-CAM-68, not shown on chart), and the 30mm spindle Over Torque cranksets using the T47-30-68/73-R/C/A. All of their bottom brackets use ceramic bearings, but you do have a choice of Race, Cyclocross, or MTB (A) bearings which have varying levels of sealing and specific grease for longevity in different conditions.

Priced at €179 which includes ceramic bearings, the T47-cam-68 Ultra Torque bottom bracket has a claimed weight of 69g for two cups without bearings, and 15g for the sleeve. They are available now.

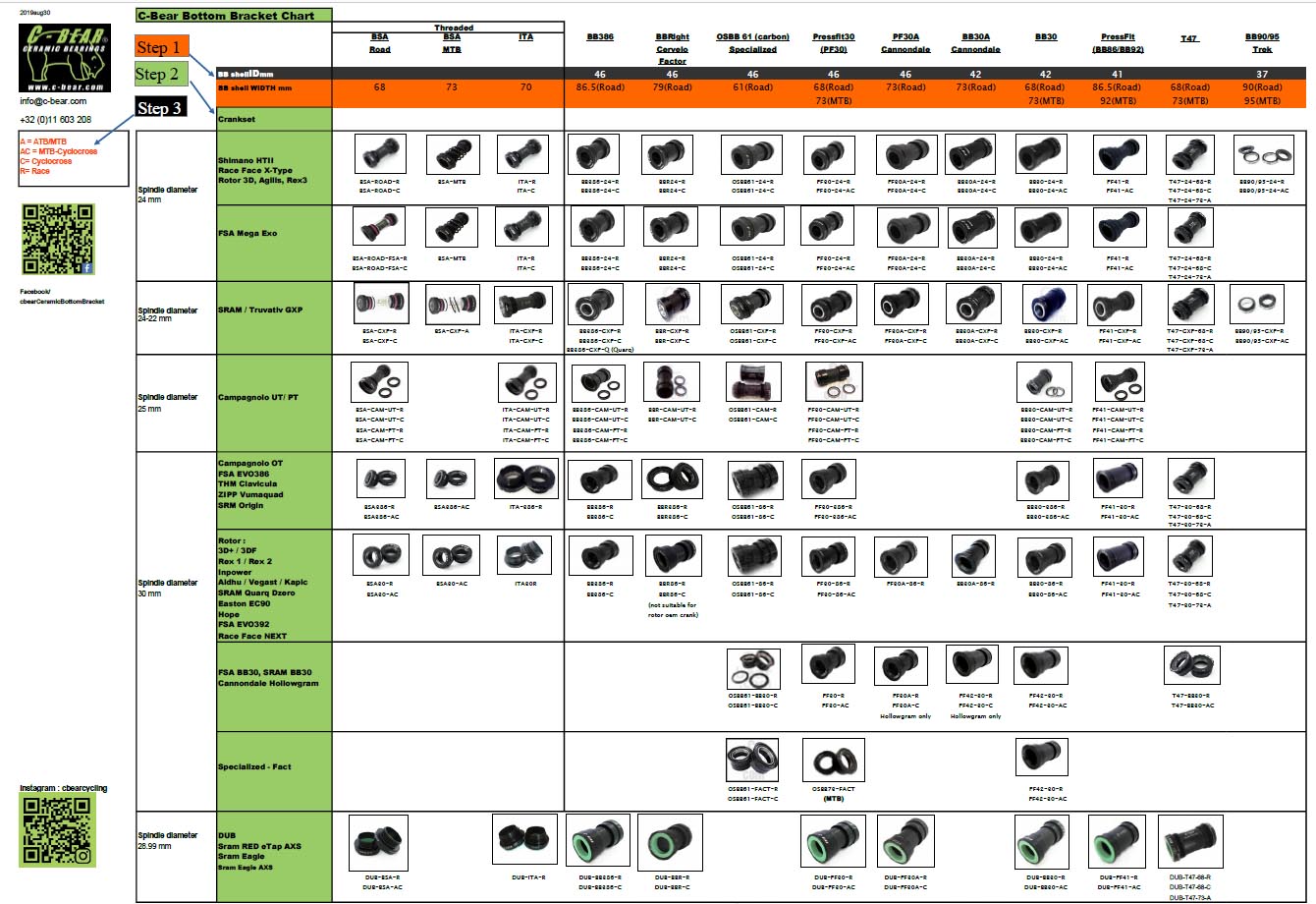

With the addition of the external cup T47 Campagnolo bottom brackets, C-Bear now has options for internal, external, 68, 73, and 86mm BB shells, and 24, 25, and 30mm crank spindles including options for GXP, DUB, BB30, Shimano, and Campagnolo. For a larger version of their Bottom Bracket Easy Finder, you can download it from their home page here.

C-Bear also points out that they have been working with a number of frame builders to improve their designs, including 22bicycles and Sturdy who have helped develop a slim fit sleeve to allow for easier cabling.