Since August 2021, road bikes rolling out of Factor have benefited from the addition of the CeramicSpeed OHD (Optimized Headset Design) that houses their new and improved SLT Bearing technology. We saw the brand’s first incarnation of Solid Lubrication Technology at EuroBike 2018, put to use in the pivots of a rear suspension platform. CeramicSpeed now tells us that, after dedicating additional time and resources in the test laboratory to further perfect the technology, these solid lube bearings are rolling out on bikes with applications for headsets and rear suspension pivots… OE at first, but aftermarket options are on the way.

CeramicSpeed SLT Bearings

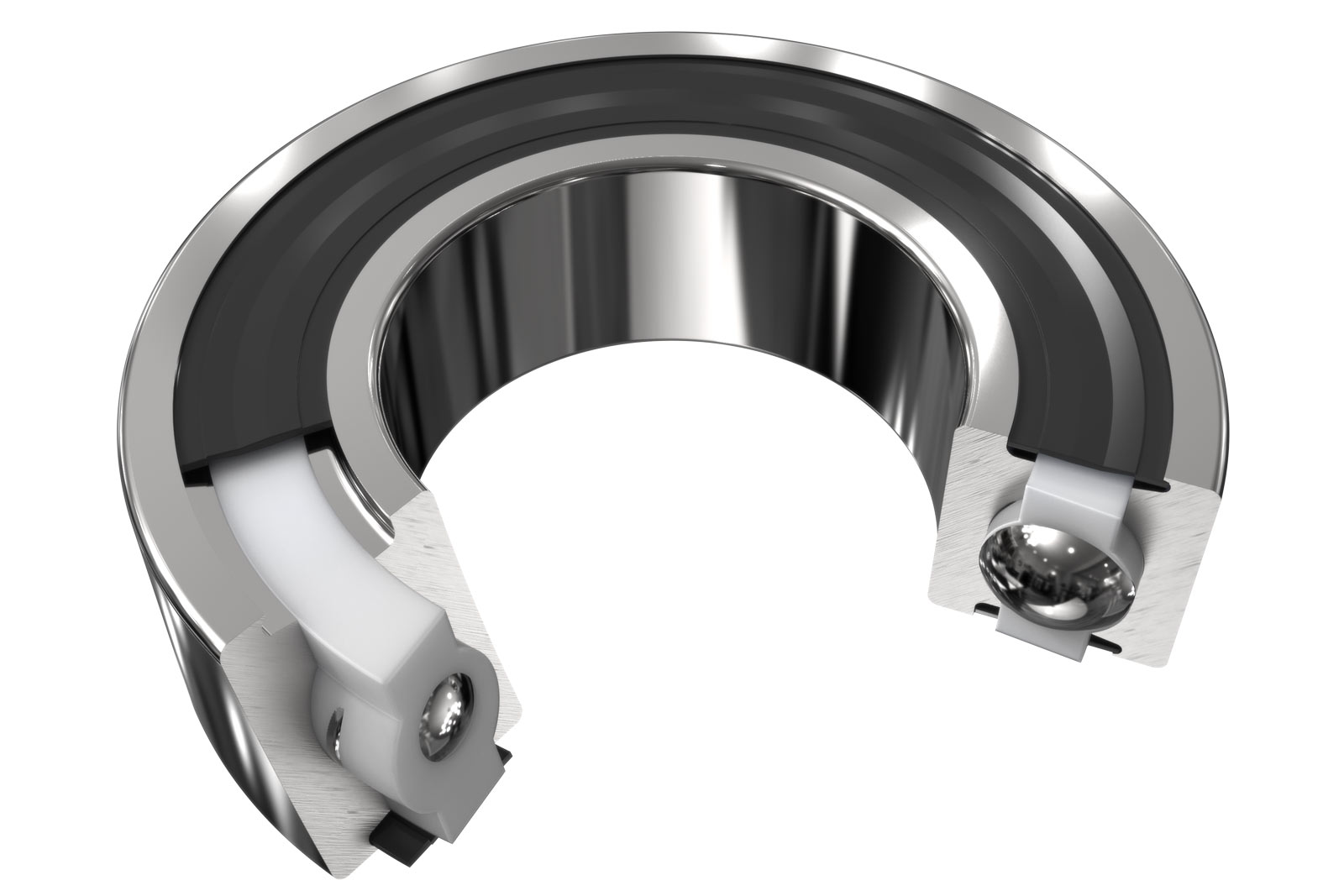

What is Solid Lubrication Technology? Typically, it refers to a bearing assembly that lacks grease entirely. While a regular cartridge bearing is lubricated by virtue of grease packed in with the ball bearings between the inner and outer race, an SLT bearing appears to run dry. Lubrication is provided by the oil-infused solid plastic polymer that holds the bearing balls in place and keeps them lubricated and protected.

The special lubricating polymer is injected into the bearing, filling the gaps between each ball bearing to fully encapsulate each one. Jonathan Small, Director of OEM Sales at CeramicSpeed, says the new SLT Optimized Pivot Design bearings that will be used on rear suspension pivots are at least three times more durable than the current market-leader, full complement pivot bearings.

Factor are the first brand to benefit from the new CeramicSpeed SLT bearings, but other OEM partners will be announced over the next few weeks and months. While CeramicSpeed componentry tends to come at a premium due to its durability and low-friction claims, you may expect those partners to be high-end road and mountain bike brands.

“High-performance race teams will be the first adopters of this SLT bearing tech. They need race after race suspension consistency in the most extreme and abusive conditions. This consistency combined with highly reduced service intervals will be why we see these bearings on world-class bikes at the races and at home”, explains Mike Garrigan, CeramicSpeed’s Off-Road Category Specialist.

Once greater compatibility has been attained through CeramicSpeed’s new OE partnerships, the Danish brand plans to bring its SLT bearings to aftermarket customers.