No matter what the product, one facet of production always seems to stir up conversation – where it was made. For years we have seen more and more overseas manufacturing, but it seems we might just be on the cusp of more coming back state side. Then there are those companies who have quietly made things here since the beginning, like A’ME. Since making their first BMX grips in the 1970s, A’ME has proudly manufactured almost everything they make here in the US including most of their heated grips which are now available in both mountain, and the heated road wraps. After a box of heated goodies showed up, we thought it would be a great time to talk to A’ME’s Bob Rutten about the company, the state of US manufacturing, and their line of heated grips.

Plug into the conversation next.

Bikerumor: Tell us a little bit about A’ME as a company? How and when did you get started?

Bob Rutten (Gripos LLC): The company name is Gripos LLC. Our grip products name is A’ME Grips. We are an injection molding company specializing in Thermo plastic elastomers and also doing other types of custom plastic molding.

Bikerumor: How many employees does the company employ today?

Bob Rutten: At this time, we have approximately 70 full time employees.

Bikerumor: How long have you been making bike grips?

Bob Rutten: We have been manufacturing grips since the mid 1970’s. During that time we have not only made our own line of grips, beginning with BMX grips, but we have also manufactured grips for many other companies along the way.

Bikerumor: In addition to bike grips, what else does A’ME produce?

Bob Rutten: As a custom injection molder, Gripos has produced a variety of products, from medical eye surgery practice models to a simple door stop.

Bikerumor: What is the biggest category for your products?

Bob Rutten: Our specialty is grips. We manufacture grips for bicycles, motorcycles, golfing, baseball, and other applications.

Bikerumor: Is everything manufactured in the US?

Bob Rutten: All of our injection molding is done here at our manufacturing plant in Las Vegas, Nevada. Most of our sub-assembly electronics are also done here and some at a facility we have in Ensenada, Mexico.

Bikerumor: There seems to be a much higher percentage of grip companies making their products in the US compared to other components. Is there any particular reason for that?

Bob Rutten: Probably because manufacturing grips in not labor intensive, the molding machines do all the work, so there is not huge savings by going off-shore for cheap labor.

Bikerumor: What are some of the unique challenges of making things here?

Bob Rutten: Government regulations and labor costs.

Bikerumor: Some of the benefits?

Bob Rutten: Having full control how our products are manufactured. Having the pride of making a product here in the U.S.A. Supplying jobs in our community. Starting a project wth hands-on development from start to finish and then producing the product at the end.

Bikerumor: How do you see the state of US manufacturing?

Bob Rutten: Very dismal right now but perhaps turning the corner to get more manufacturing back here in the U.S. I think people are beginning to realize the importance of having manufacturing companies remain here and employing our U.S.workers.

Bikerumor: How long have you been making the bicycle heated grips now?

Bob Rutten: We are now in our third cold season of having heated grips available for retail purchase.

Bikerumor: What’s new in the heated grip world?

Bob Rutten: We are, I am not aware of another heated grip available in the bicycle industry. We also produce a line of heated grips for the motorcycle industry.

Bikerumor: Any new products on the horizon?

Bob Rutten: We are constantly striving to improve and add to our heated line of grips. We also have plans for a couple new BMX and Mountain Bike grips.

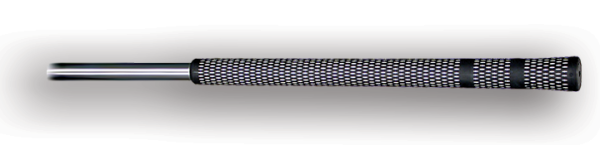

A’ME Heated Road Wraps

After spending a quite a bit of time on the A’ME heated mountain bike grips, I am looking forward to trying out the heated road wraps. Since the heated wraps are located under the bar tape, the system definitely takes more time to install and remove than the lock on mountain bike grips, but the road wraps have an additional wire segment that includes the on/off switch so that you can remove the wires and battery leaving the wraps in place.

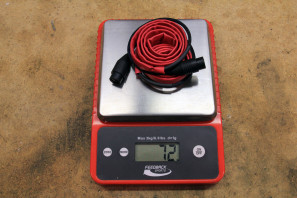

Designed to cover approximately 5-6 inches of a road handlebar, like the mountain grips the wraps work best on carbon bars since metal bars act as a heat sink and draw heat away from the target. If you are using the wraps with a metal bar, A’ME includes cork adhesive tape to place between the wrap and the bar to isolate the bar from the heat source. The total weight for the system clocks in at 536g (521g without the cork tape) which includes the wraps, wires with on/off switches, battery, battery holder, and battery strap. With 6 temperature settings for each side of the grip, the bluPulse Adaptive Thermal Regulation keeps the bars at a constant temperature indicated by the blue LED. The system retails for $199 – same for the mountain bike system, which was a substantial drop from their original retail price.

Will the heated road wraps work as well as the heated grips out on the road? Still plenty of Winter left to find out.