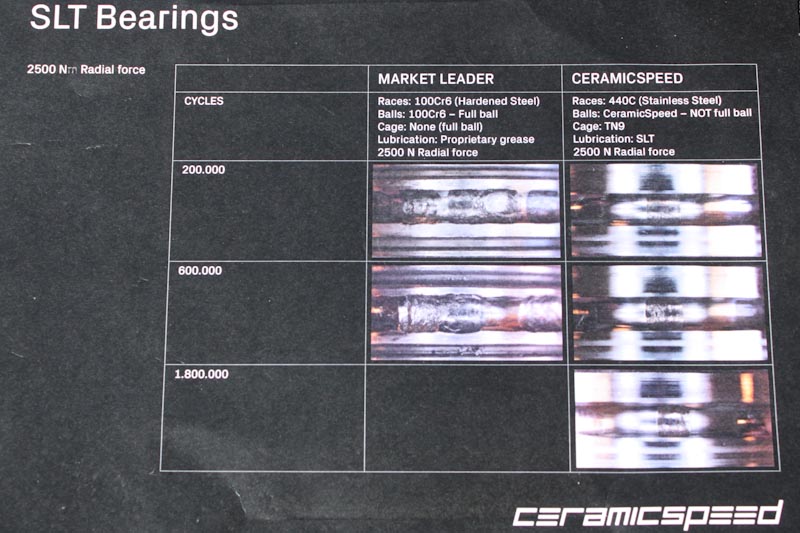

Well, it seems as though Ceramicspeed has finally decided to play dirty! After many years of developing high-performance bearings for road riders, they’re now stepping to the MTB table with an intriguing first offer- Pivot bearings that will last for at least four years with no maintenance.

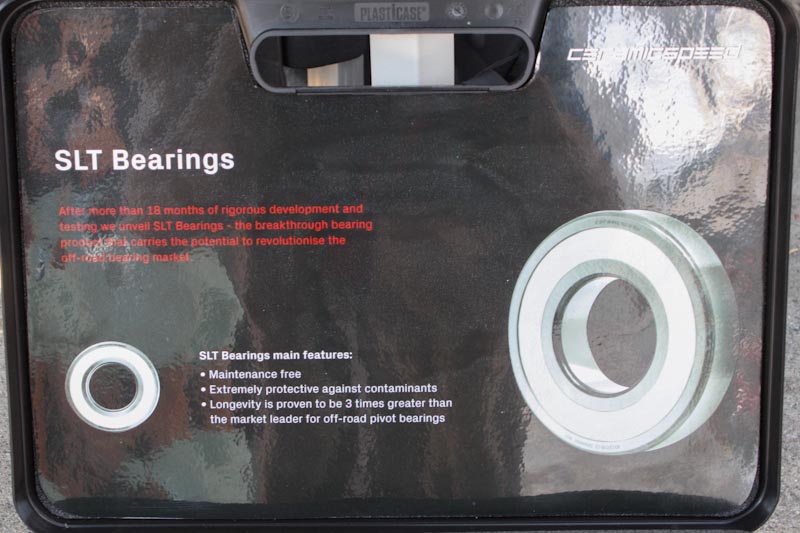

The most interesting component of the Ceramicspeed SLT pivot bearings is their lubricant. See the white piece that’s sitting where the seal would normally cover? That’s the lube, also seen on its own in the tray to the right. It’s a plastic polymer that starts as a liquid, then gets infused with oil and baked at over 150ºC (302ºF) changing it into a solid form.

The polymer fills up the bearing like an ice cube tray, and is cooked into the assembly. The solidified polymer fits so precisely around the races and ball bearings that it very effectively seals the bearings and cage on its own, without a typical seal. In MTB applications the production bearings will still use seals, but they’re merely for UV protection.

This polymer technology was actually created for the bearings Cermicspeed makes for meat processing machinery, which gets powerwashed daily. These bearings have been in use for two years already, and that’s how Ceramicspeed estimated the 4-5 year life span for them. So, feel free to hose down your bike.

Word is this solid polymer lubricant is ideal for applications where the bearings move back and forth rapidly, rather than spinning continuously as wheel bearings would. So, don’t expect it to show up on wheel or drivetrain bearings anytime soon.

The lubricant works in temperatures exceeding 100ºC (212ºF), which is well over what it would endure in a bike frame. Oil infusion life is 4-5 years, and again there is no maintenance required. Eventually the polymer lubricant layer will dry out, but until it does it should deliver consistent performance.

While many pivot bearings are full-ball style, (built with ball bearings completely circling their inner race) Cermicspeed’s SLT bearings use a cage assembly with anywhere between 8-12 ball bearings.

Pivots aren’t the only application for the SLT bearing tech- Ceramicspeed is also already working on headset bearings too. Since the company already makes headsets, these might actually beat the pivot bearings to the aftermarket.

The pivot bearings will first be marketed directly to manufacturers, as OEM equipment for high-end bikes. Depending on who hops on board and how quickly, they could begin to appear on 2020 model year bicycles. Cermicspeed does hope to move these bearings into the aftermarket, but the massive range of bearings out there (some bikes have up to 12 bearings, and there are no industry standards) will likely take a while to sift through. Consumers will likely see some of the bigger MTB brands’ bikes covered with upgrade kits first.

The SLT pivot bearings will cost more than other high-end bearings that are currently available (exact pricing is not yet determined), but Ceramicspeed feels their longevity will more than offset the cost difference.

And just for fun, Ceramicspeed had this interesting little piece to show off too- This tiny bearing was developed for a European telecommunications satellite. It had to be maintenance free, and withstand five G’s of force to survive takeoff.