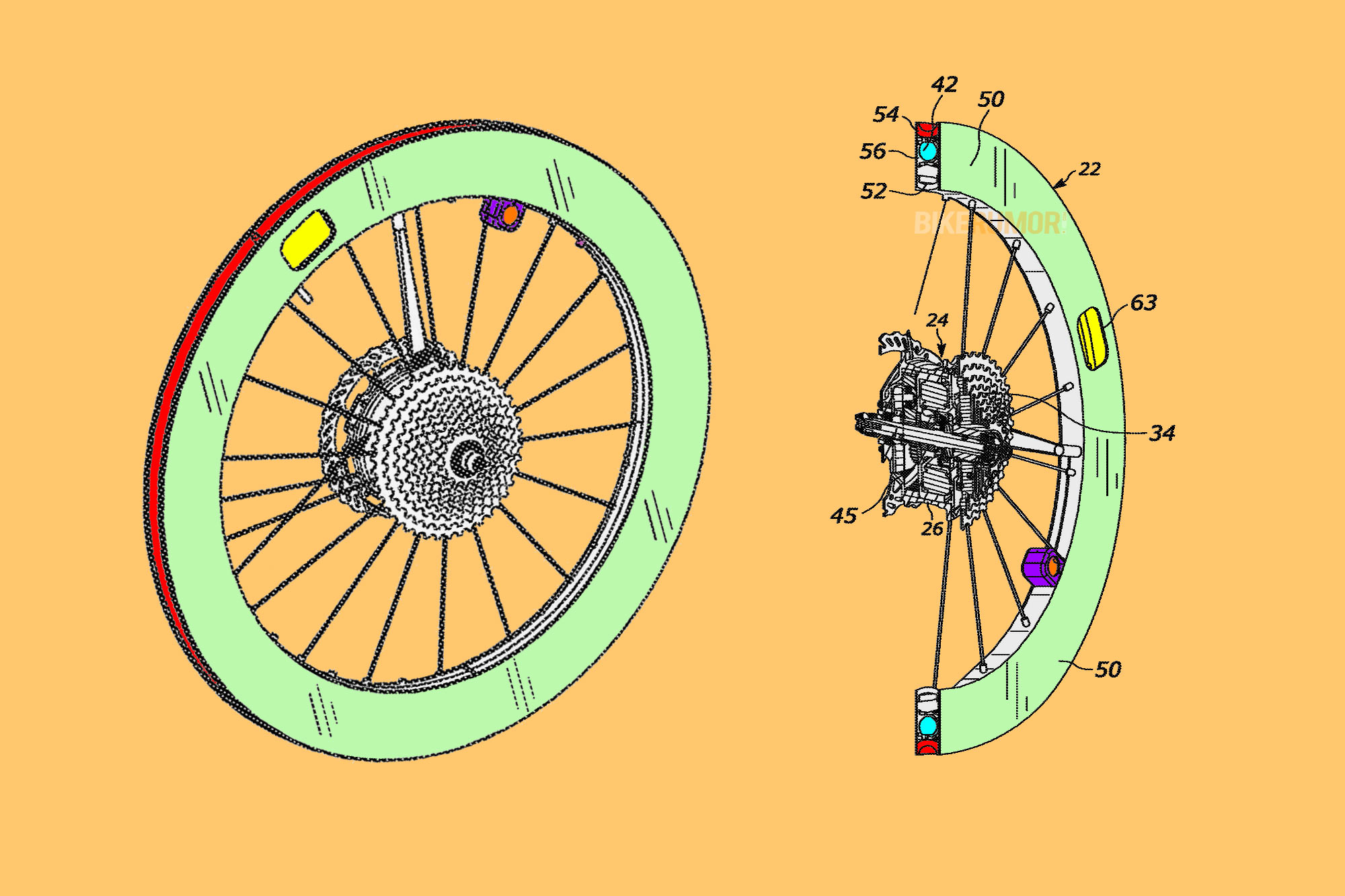

A recent patent from Cycling Sports Group details a new “Bicycle Power System” wherein a string of battery cells are located inside the circumference of the rim of a rear wheel and configured to a hub drive motor to provide pedal-assistance. The system places all the necessary components for electronic pedal-assist inside the rear wheel, offering up a way to, theoretically, convert any bike to an eBike.

While the concept isn’t entirely new, the positioning of the batteries inside the rim, so far away from the axis of rotation, is. With it comes improved heat dissipation and claimed benefits for battery efficiency and lifespan. The design is interesting from a utility perspective rather than a performance one; here’s an insight into how urban eBikes of the future may be powered…

CSG Patent for a New eBike Wheel

Cycling Sports Group is owned by PON Holdings, an industry behemoth responsible for some big name brands including Santa Cruz, Cervélo, Focus, Cannondale, and GT, but also some notable urban mobility-focused brands such as Charge, Schwinn, Gazelle, Kalkhoff, Veloretti, and Urban Arrow. To give you a sense of scale; the PON website informs us that one in five eBikes in Germany are made by a PON brand. I am no patent lawyer, but I reckon the ownership structure means the technology described within CSG’s Patent for a Bicycle Power System could foreseeably be rolled out far and wide.

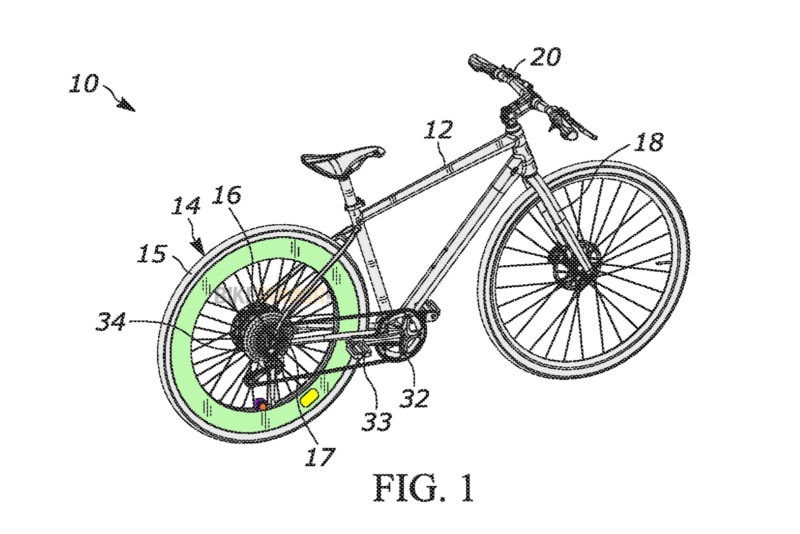

The patent (US 2023068251) shows the Bicycle Power System in use on a fairly standard-looking flat bar hybrid/commuter-style eBike. But, the patent description does mention it could equally be applied to a mountain bike – hardtail or full-suspension. Though, it does seem highly unlikely it would find a home on such performance-oriented bikes where an inordinately heavy rear wheel would have its disadvantages for overall bike handling – not to mention the idea of having so much mass located toward the outer edge of the wheel where the weight would be felt even more so. No, we reckon this Bicycle Power System is very much intended for the urban mobility crowd.

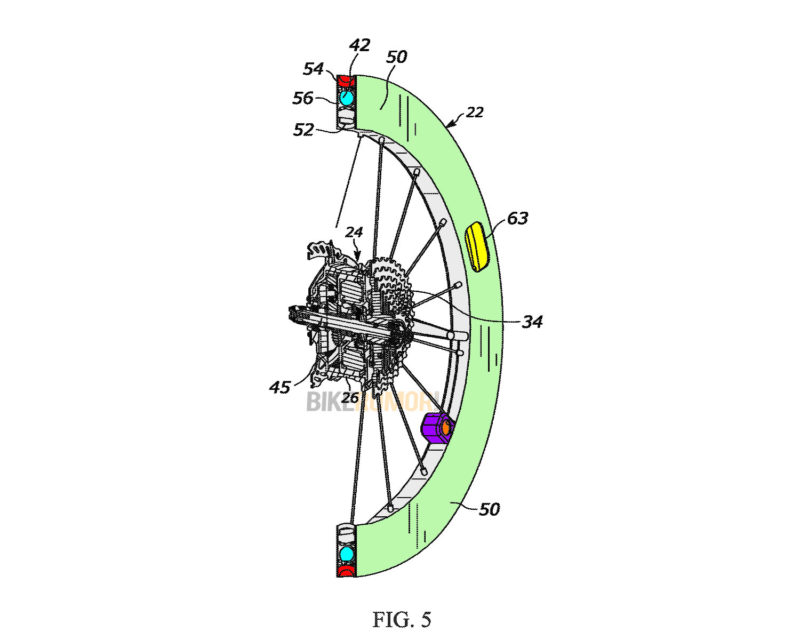

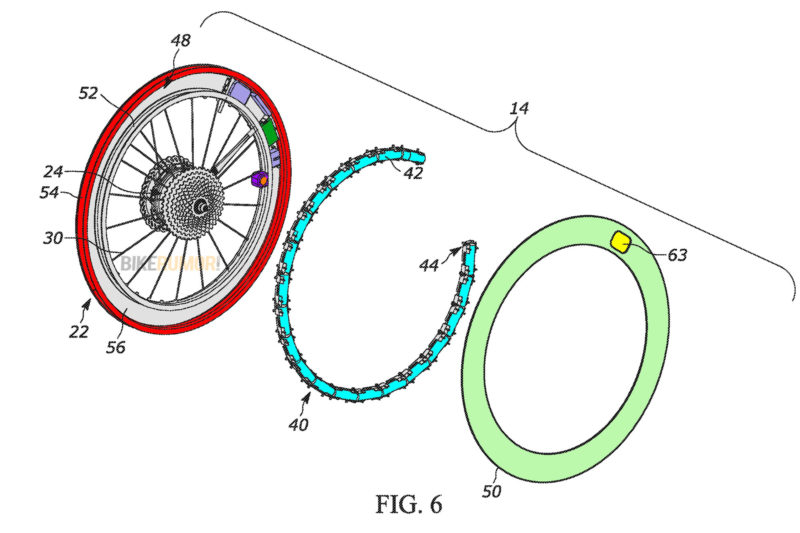

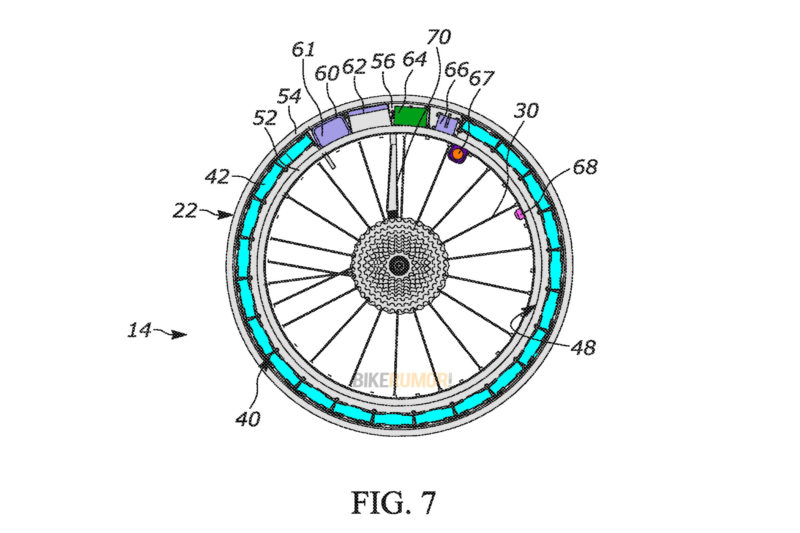

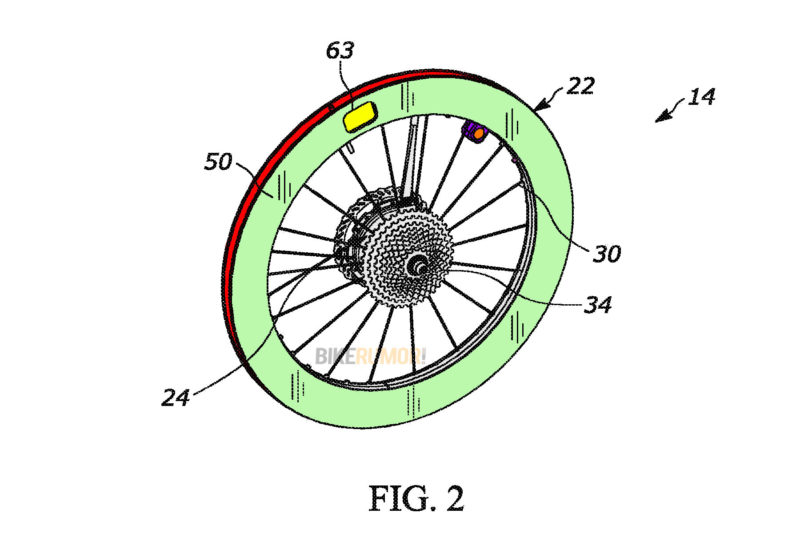

Briefly… a hub drive motor is connected, via cables running through hollow spokes, to a “sausage-string” (cyan) or circular one-piece battery arrangement disposed within the hollow of the deeper rim (56). The batteries are positioned far away from the motor, where they cannot be affected by any heat generated by its function. And, the tandem arrangement gives a high surface area to volume ratio, which itself will encourage better heat dissipation.

The main benefit here is that the batteries could run more efficiently. As compared to a system wherein the batteries are housed around the hub drive motor this one could have a much longer range, or it could have the same range in a lighter-weight package.

Isn’t this design terrible in almost every other way?

Maybe. It seems that damage to the rim could easily damage the batteries, if not the entire electrical system, sending a lot of material to the dumpster. And while it would be easier to cool, we also imagine it would be more exposed to dirt or water infiltration. That said, the patent does describe an embodiment in which the batteries held within their “carrier wreath” and the Battery Management System that is also housed within the rim, could all be removed from a damaged rim and installed within a replacement rim.

Placing so much weight so far away from the axis of rotation would also almost certainly have negative implications for general handling, too. Probably not enough to be prohibitive in the world of commuting and cargo transport, though, two areas where such technology is most likely to find its home.

Could this technology be utilized to make any bike an eBike?

Sure it could, theoretically, but only if its owner wanted to engineer it that way. A benefit of this system would be that you don’t need to find space on your frame/bar to mount a separate battery pack because it comes as part of the wheel itself. And, all the wired connections are relatively self-contained.

There are plenty of eBike conversion kits on the market, and we don’t really think any of CSG’s brands would be looking to compete with those companies directly. More likely, this technology will be rolled out on a future Charge/Schwinn/Gazelle/Kalkhoff/Veloretti eBike boasting an improved range/weight ratio over its competitors. Or, they could sell it as an upgrade to one of their non-eBikes.