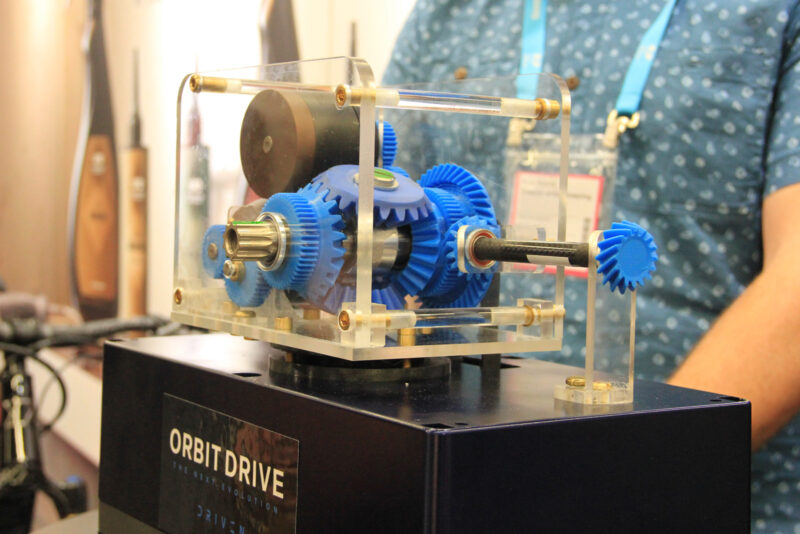

Driven, a new company spun out of CeramicSpeed, has shown its innovative Orbit Drive transmission for the first time at Eurobike, Frankfurt. The working prototype of this all-in-one gearbox eBike motor weighs a claimed 4.6 kg – including all gears, electronics, and power delivery to the rear wheel – and can be configured to produce up to 90 Nm torque.

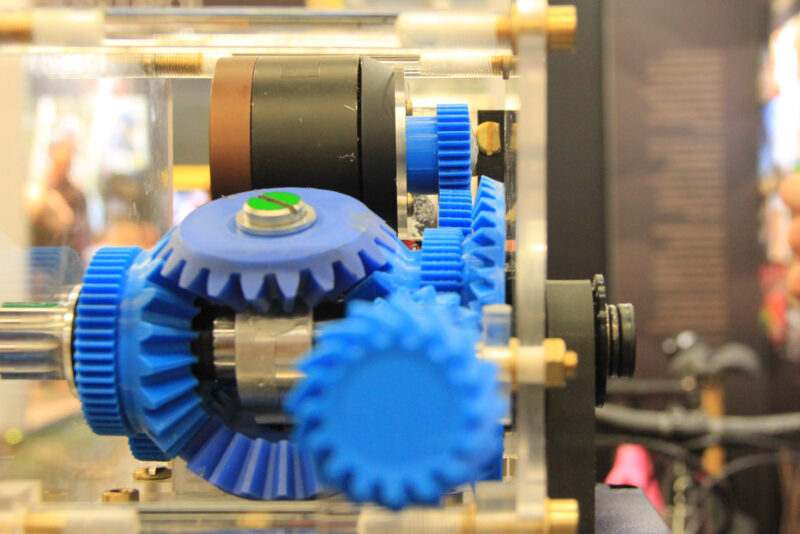

The design takes inspiration from systems found inside hybrid cars – like the Toyota Prius, for example. Therein, planetary gears are utilized to mesh the input of the combustion engine with the input of an electric motor, to deliver power to the vehicle.

Driven are taking that concept and, instead of using flat, planetary gearing, their Orbit Drive relies upon a rotating ball-like mechanism that delivers a variable speed ‘bevel differential’. Though the layout is certainly not novel, its application in eBike technology, is.

We are told by Driven, “This is a game changer for the e-bike segment, bringing the highest level of efficiency (more battery range), a more pleasant riding experience, almost zero-maintenance, and a bolt-on solution for e-bike manufacturers”.

Here, Driven’s Head of Engineering, Ryan Norris, takes the time to explain the mechanism using a neat 3D printed model of the concept. And, he does so in terms that don’t require a PhD in mechanical engineering in order to comprehend.

Driven Orbit Drive All-in-one Gearbox eBike Motor

The Driven Orbit Drive is a little further along in its development process than the above 3D printed model might suggest. The company has a working prototype they say is significantly more efficient in its energy usage than any production eBike motor on the market today – upward of 85%, is the claim.

Not only that, but maintenance intervals are set to once every 10,000 miles, with only an oil change required at that point. Clearly, such a design boasts some serious advantages over commonly available eBikes that rely upon a motor and an entirely separate derailleur-operated drivetrain – the pitfalls of which many of us know all too well.

Driven tell us their system also offers a smoother ride experience, with an automatic mode offering step-less shifting with gearing automatically adjusting speed, with the assist motor complementing the rider’s input. Manual mode is also possible, allowing riders to shift through gears as they would on what Driven are calling a “legacy bike”, i.e. a regular bike.

In addition to the claimed higher efficiency over comparable systems, we are told the Orbit Drive also has a regenerative braking feature to compound that.

Driven plans to offer three variations on the Orbit Drive to its OEM customers:

- Direct Drive – this configuration uses a shaft drive to deliver power from the Orbit Drive to the back wheel. This is the brand’s most efficient unit and it is fully enclosed

- Chain Drive – the Orbit Drive with a chain, partially enclosed

- Belt Drive – the Orbit Drive with a belt, partially enclosed

We asked Brian Baker, CEO of Driven, why has no one done this yet. His answer…

“One of our marketing pitches is – why hasn’t anyone done this? I’ve been the CEO for one year, and I do not have an answer for that. Everyone took what they are doing at Toyota, on the Prius, and at Stellantis for example – those are all flat planets and sun gears. All we did was take the planet and do that [make it that 3D orbit shape]. Now, it fits right in the middle of a q-factor, and we can get a 1:1 ratio out of the motor. We don’t have to downshift the motor, so we can use smaller motors, and so this whole thing works quite a bit better than a flat, planetary system”.

Driven has more technology packed into there, too. Unlike most eBike motors on the market today, this one lacks a torque sensor, at least in the traditional sense. Driven hold a key patent for a sensor-less torque sensor.

CEO, Brian Baker, explains…

“There’s an algorithm we’ve developed based on how much torque you’re putting into the system – and thus how much torque the motor sees – from that you can calculate the speed, so you don’t even need sensors at all“.

Ryan Norris continues…

“We’re using the electronics of each motor, and how they talk to each other. So, when they sense you pressing down on the pedal – they know it within about 40 ms, and we’re gonna get that down to about 20 ms, so that’s as fast as a regular torque sensor is. So, we don’t need the torque sensor. And torque sensors are actually pretty expensive, so we’re actually pretty excited that this algorithm works. It’s nothing new. It is used in industrial mechanical design all the time but no one has ever used this in the bike industry before”.

How much will the Driven Orbit Drive actually cost eBike manufacturers?

We are told that, in terms of the Ride Share market, the Orbit Drive will come in at a middling price point – more than the $800 USD that the cheapest offerings go for, but less than the $1,500 USD that higher-end options go for.

Brian goes on to tell us he is confident that gearbox eBike motors of this design, and similar, will become the most common design in the market over the next 10 years.

Indeed, with the launch of Pinion’s Mission ON:E eDrive earlier this week, the industry certainly seems to be pressing on with integrated solutions to shifting and assistance. Likely, we will see many more such offerings on display in the vast halls of Messe Frankfurt this week.