Standing out against the sea of marginal gains, concept bikes allow a company to flex their design muscle and dream up something wild. For BMC, the Impec Concept project was more than just creating a new bike as they wanted to really show off the capabilities of the Impec Advanced R&D Lab. As the same lab that puts out the woven carbon fiber used for the BMC Impec Road Bike, the facility is capable of turning out complete machines from concept to completion in record time.

When it came time to do something new, BMC’s engineers and designers tried to envision what a road bike would be in the future – and then built it. Using the advanced resources at their disposal, the Impec Concept came together in just 4 months with a few design features actually seeing real world testing on other bikes. Using modular integration the bike is built with a basic structure designed for a number of add ons…

While certainly not the first bike to use a single sided fork or swingarm, BMC says they imagined the design since reducing the frontal area as much as possible will reduce drag.

Obviously the future is disc brake compatible, and the Impec concept is no different. The interesting part is the integration of the calipers into the frame and fork and the ram air scoops that force air into the rotors to cool them.

The drivetrain concept takes the modular ideal up a notch. Consumers could purchase a drivetrain module of their choice and simply install it into the bike. Want different gearing? Just change the module.

Aerodynamics were a big part of the design which is why the bike uses a twin spar stem and seat tube. The 70mm spaced stem spars drastically, and we do mean drastically, decreased the amount of turbulence coming off the front of the bike in CFD testing. In addition to being more aerodynamic, the widely spaced struts allow for an integrated stem that is extremely stiff.

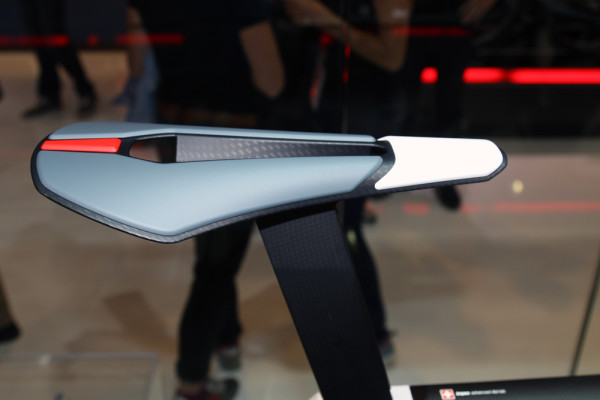

Integration continues into the bars with advanced electronics elements. The saddle is a single piece without rails that is still adjustable and has actually been ridden on other bikes.

Ultimately the BMC Impec Concept is just that – a concept. But the project shows just what BMC is capable of, and in a very short period of time. Having the ability to design a product and then simply walk next door to check on the development is what the Advanced R&D Lab is all about. Well, that, and making amazing bikes.