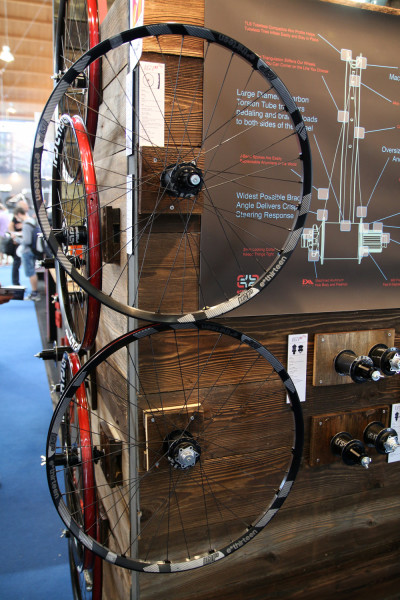

While many companies have a few new products for trade show season, but in the case of e*thirteen almost everything in the booth has at least changed. From chain guides to wheels, to completely new products like their tubeless sealant, e*thirteen is bringing the goods. After integrating the Hive hubs into their wheels, the product story has always been about placing the mass where it matters the most which is usually around the hub. In order to demonstrate their wheel design, the company had a pretty interesting display which you can see in action after the break…

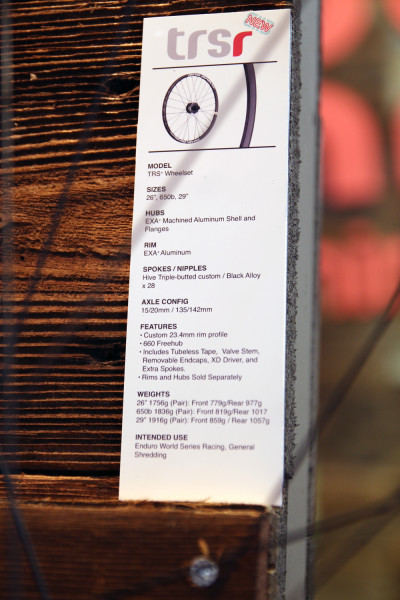

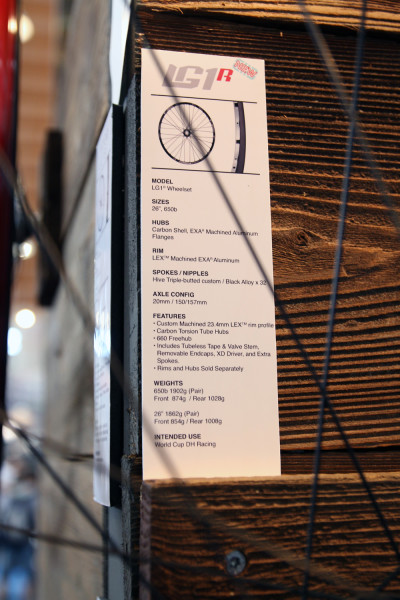

On the wheel side, the biggest change is new LEX machining to the rims. By removing material where it isn’t needed (like the spoke holes on the lower tension side) e*thirteen was able to remove about 20g per rim while keeping the same strength. The newly machined rims will be found on the Lg1 for DH use, and the Trsr for trail and enduro. The Trsr wheels are available in all three sizes with 15/20mm and 135/142×12 axle compatibility, but the Lg1 is 26 and 27.5″ and 20mm 150/157mm only. Both wheels feature at 23.4mm wide rim channel.

Click on the photo to enlarge for weights.

The hubs continue with their 60 points of internal engagement, a carbon shell, and one of our favorites – steel inserts in the aluminum cassette body to keep the cassette cogs from digging. Wheels are shipped with Shimano and XD freehub bodies in the box, pre-taped for tubless, and include extra spokes.

Above is the display that got everyone talking. The two wheels weigh exactly the same, but one has the weight centered around the hub and the other has the weight towards what would be the rim. As you can see the wheel with the weight towards the center accelerates faster than the other which e*thirteen uses to show that it’s more important to save weight at the rim rather than the hub.

One of the products we didn’t expect to see on e*thirteen’s shelves was a new tire sealant. The space age sealant uses oxyplatelets that go to the source of the leak and begin to plug the hole by sticking their hands into the cuts. Ok, oxyplatelets might not be little creatures plugging holes, but it is a non-toxic coagulating sealant. In development for 2 years, it is based on an acrylic binder with particulate matter to seal up to 4mm cuts.

e*thirteen will also be offering their own tubeless kits that use the same nylon based tape as their wheels. The kits will include their new super light aluminum tubeless valve which has been designed to be more robust than standard offering. Designed with a bigger diameter, the valves will still fit standard wheels and pumps. Sealant will be available in 250ml bottles for 2 tires, or 1000ml bottles for 8.

Chainguides have always been e*thirteen’s bread and butter, and the new crop are some of the best yet. The Plus level guide has been reworked with technology trickling down to the Race and Base level next year. Designed to be more modular, the guides have a removable lower roller and have different direct mount bash guards for 30, 34, and 38t rings. The honeycomb pattern you see on the back of the guides makes it so that under harsh impact the guide will deflect away from your crank, hopefully saving the pricey bits.

Other improvements include tool-free openings on the upper guides, more rotation adjustments, a new PC formula that isn’t prone to solvent contamination, and quieter performance thanks to a co-molded upper guide with shore 80 rubber inserts and a smaller profile rear roller. Guides will be available in black or grey.

Many of the changes have also made their way to the top guide and High Direct/seat tube guide.

Fans of the e*thirteen cranks will also be happy to see the updates which should make them more durable in the long run. In addition to simple things like adding clear protective skins on the crank arms, the polygon shape has been updated with a new 1 degree taper instead of the original 3. The change results in more surface area for 18% increase in strength while being easier to install and remove and no additional weight.

The press fit bottom brackets have been updated with post machining around the bores for better tolerance and threaded sleeves for all models. A new external shield will help the bearings spin freely in the worst conditions and the APS adjuster will now only rotate one direction making installation easier.

bythehive.com