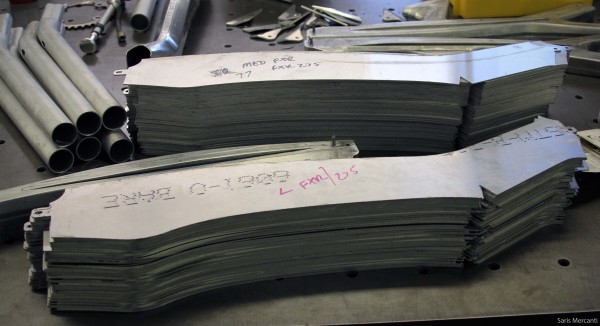

Every bike begins here, with a water jet cut piece of aluminum

Every bike begins here, with a water jet cut piece of aluminum

At a time when the cutting edge of mountain bike suspension technology features 2″ of supple elastomer based travel, Foes Racing was pioneering long travel suspension and helping push the limits of the downhill race scene. Leaving other companies to argue over the benefits of suspending the rider or the bike, Brent Foes helped push forward innovations by experimenting with the little understood field of suspension, and creating the distant ancestors of today’s modern “Enduro” bike.

Over twenty years later, Foes Racing continues to push the envelope. With suspension technology having finally caught up to the vision and capabilities of the bikes they’re paired with, the company can now focus on continuing the legacy of building burly aggressive aluminum frames for which they rose to prominence.

During a recent trip to Southern California, we had the privilege of stopping by the Foes Racing Factory in Pasadena to get a closer look at how these legendary frames are created from flat sheets of aluminum.

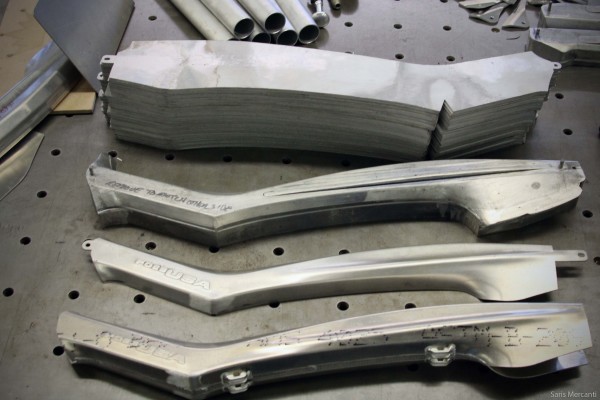

The aluminum top tubes are formed into distinct shapes by a fifty ton press. The process involves placing the precut sheets onto dies, which are left and right specific. Brent constructs the original prototype dies from wood, but they can only survive maybe a dozen uses. Once they’ve finalized the design, they create aluminum forms.

The aluminum top tubes are formed into distinct shapes by a fifty ton press. The process involves placing the precut sheets onto dies, which are left and right specific. Brent constructs the original prototype dies from wood, but they can only survive maybe a dozen uses. Once they’ve finalized the design, they create aluminum forms.

This press was built in 1953 for aerospace manufacturer Lockheed Martin, but has since been converted for bicycle manufacturing. One of the advantages of this system is that different durometer pads can be substituted to alter shapes.

From top to bottom: Precut aluminum sheets, the final mold constructed by Brent, half a hydroformed top tube, and a tack welded top tube.

The downtubes are hydroformed at a separate local facility.

Brent builds a jig for every model.

The aluminum dies used to produce every model (both current and historic) are stored throughout the factory.

Half the shop floor is dedicated to raw materials, partially constructed frames, and Brent’s welding station, while the other half houses American made Haas CNC machines. Headtubes, linkages, and everything in between are formed here from raw materials.

In addition to manufacturing bicycles, Foes also produces an assortment of things for movie studios, which we’ll cover in Part 2 of our Factory Tour coverage.

Each frame is then assembled and locked down in place on a welding jig.

Each frame is then assembled and locked down in place on a welding jig.

Now that the various components have begun to take the shape of a bicycle, they are welded by Brent.

When we were at the Factory earlier this year, we heard rumors that the Brent was considering doing some customized frame geometries for customers. Interested? Let them know in the comments

From afar, you might be tempted to assume that Foes racing is like any large production facility, but seeing the process up close gives you a very different insight into the process. Each frame is hand welded by Brent and the production batches are fairly small. For any given initial model run, they only make something like 10 frames per size.

Buying a Foes Racing frame is akin to purchasing a custom bike from an artisan builder. Not only is the craftsmanship incredible, but you also get the feeling that the bikes are built to last until long past the next big trend in mountain biking.

The Foes Factory consists of two buildings. One which houses the majority of the CNC machines and welding fixtures and the other where frame assembly takes place.

The Foes Factory consists of two buildings. One which houses the majority of the CNC machines and welding fixtures and the other where frame assembly takes place.

As we were saying our goodbye to the employees in the main CNC area and walking out towards the second building, we passed by a dark room that when lit revealed a full suspension assembly room. It may have only been presented to us as an afterthought during our tour, but a few years ago this was home base for the Foes in house suspension products.

While the company no longer really manufacturers Curnutt forks or shocks, they still have all of the tools on hand to work on them.

While the company no longer really manufacturers Curnutt forks or shocks, they still have all of the tools on hand to work on them.

The neon monster green paint scheme on the right is a new custom color scheme they are now offering

The neon monster green paint scheme on the right is a new custom color scheme they are now offering

Across the driveway there is a separate building which houses a 50 ton press, an assortment of metal working machines, a spare pit bike or two, and frames waiting to be assembled.

After Brent welds a batch of frames, they are sent to a local heat treatment facility. This is a two step process. In the first half, frames are heated and then put in a freezer to halt the hardening process. Then Foes employees hand check each frame to ensure there are no alignment issues, then the frame goes back into the oven for a second round of heat treatment.

After the final heat treatment, the frames arrive back at the Factory, where they receive another round of QC tests.

At the moment, Foes bikes are only available as a frame only option, but the company has plenty of fancy bits laying around to build up prototypes rigs, etc…

And for making it this far, here’s Ruby, the Foes Racing Mascot

Stay tuned for Part Two of our Foes Racing Factory Tour, where we’ll explore some of the awesome projects Brent has floating around the office.