Nestled deep in the coastal redwood forests of Northern California, acclaimed custom builder Rick Hunter quietly builds hand made bicycles for clients from around the world.

Nestled deep in the coastal redwood forests of Northern California, acclaimed custom builder Rick Hunter quietly builds hand made bicycles for clients from around the world.

Starting with steel tubing, and dabbling in carbon, over the past twenty years he has created a reputation for clean lines and a unique aesthetic.

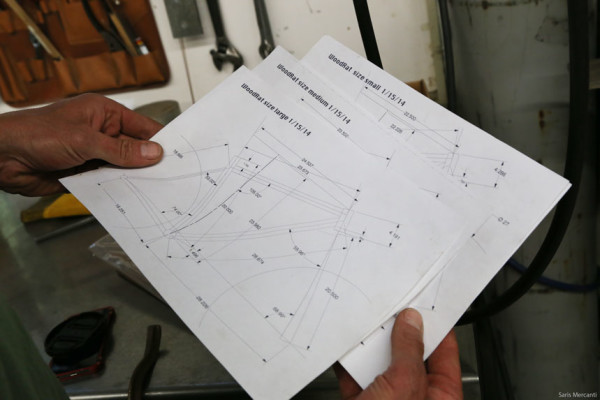

Each frame begins on paper. While Rick has achieved prominence due to his custom frames , he also builds small production batches for stocking dealers.

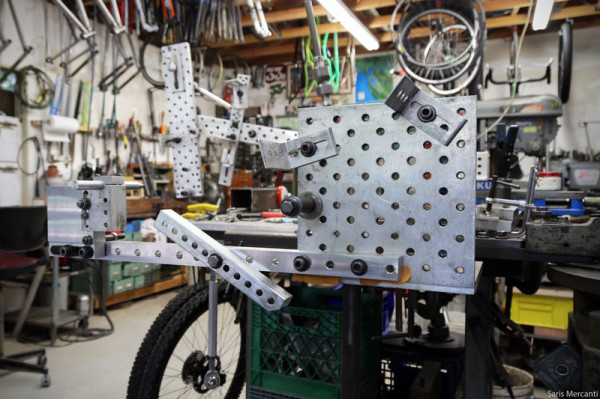

The numbers are translated into steel via one of Hunter’s two custom jigs.

Rick created these units many years ago because commercial jigs were not yet available. They would have also been out of the price range of a young hobbiest frame builder.

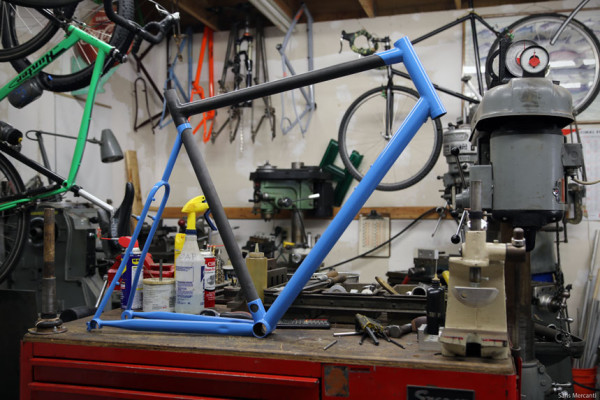

Traditionally, Hunter frames have been built from steel, but he began experimenting with carbon several years ago. At first, it was just top tubes, but this prototype features both a carbon seat tube and top tube.

Each carbon tube helps shave about a quarter of a pound, and also ads additional strength and stiffness. He purchases the carbon tubes from Rock West composites, then sends them out to Ruckus Components (factory tour here) to have the sub assembly completed. When the parts arrive, he uses a two part epoxy process to complete the frame.

Rick recently finished building this hardtail for himself. He’s a touch shorter than the average NBA player and prefers not to ride with a hydration pack, so he’s been known to squeeze 3, 4, and even 5 water bottle mounts on his frame.

That distaste for riding with a pack has also lead him to collaborate with Porcelain Rocket on a little fanny pack side venture.

He’s also experimenting with a similar carbon process on his cyclocross frames.

We feature lots of incredible frames on this website everyday, but this simple frame has to be one of my all time favorites.

Many custom builders purchase premade dropouts, headtubes, and bottom brackets from machine shops like Paragon, but Rick prefers to make everything in house.

Both his front forks and rear dropouts utilize the same convertible pinch bolt system to make his bikes compatible with any number of current and future standards.

Rick also builds his own forks in house. This combination of burly welds and delicate arches is one of his signatures.

While he has been recently doing more and more small batch runs, Rick is a custom builder at heart. Whether you want disc brakes on your road bike or fancy a fattie, he can make it make happen.

Scattered throughout the shop and lining the rafters are dozens of spare parts.

Like his frame jigs, Rick has built, customized, and even bartered for many of the machines in his shop. Some didn’t exist when he started, while purchasing others new might have been too cost prohibitive.

Behind the row of metal working tools hang several of Rick’s personal bikes.

Like any good shop, Rick has countless small drawers filled with various fasteners and other odds and ends.

The walls of the shop are largely uncluttered but little details like these pins give the space character.

Just a few pedal strokes from his workshop is Rick’s glorious pumptrack.

To tear the berms a new one, he built a small batch of dirt jumper frames. At well over 6 feet, on his personal bike he uses a setback post, and handlebars with a lot of rise.

He is currently working with Nitto to develop a line of handlebars. We’ll share more details on that project as we get them…

In addition to all of Rick’s personal bikes, this little Pixie was also hanging from the ceiling in the workshop. One of three, this one was originally built for his nephew. The other two can be seen around town being ridden by two up and coming rippers.

It may be for kids, but it would probably be the ideal Parkfield Pixie Bike.

And for making it this far, here’s a picture of Rick’s best friend Woody.

There is currently a year long wait time for a Hunter frame, but you can learn more about his custom builds, or check out the online store here.