Earlier this month, we had plans to visit the headquarters of Rolf Prima in Eugene, OR. The plan was to check out their space, get the full factory tour, and hopefully ride some Rolf equipped bikes. When we were planning the trip, we had no idea that Rolf was about to launch a new line of rims. Then, Rolf made the announcement that they would be offering U.S. made aluminum rims with non-paired spokes under the name Astral by Rolf Prima. All of a sudden, the trip was more than just a factory tour – don’t worry though, that’s coming soon. But first, Astral rims…

While it may seem like Astral is Rolf saying uncle on paired spoke designs, to co-owner Brian Roddy it’s a way to double down on the superiority of the paired spoke deign. They still firmly believe that when you take the time to design and engineer the hub and the rim together you end up with a better, stronger, and lighter rim with a paired spoke lacing pattern. But at the same time, Brian says that if you can make a rim work for paired spokes, you can definitely make it work for traditional lacing.

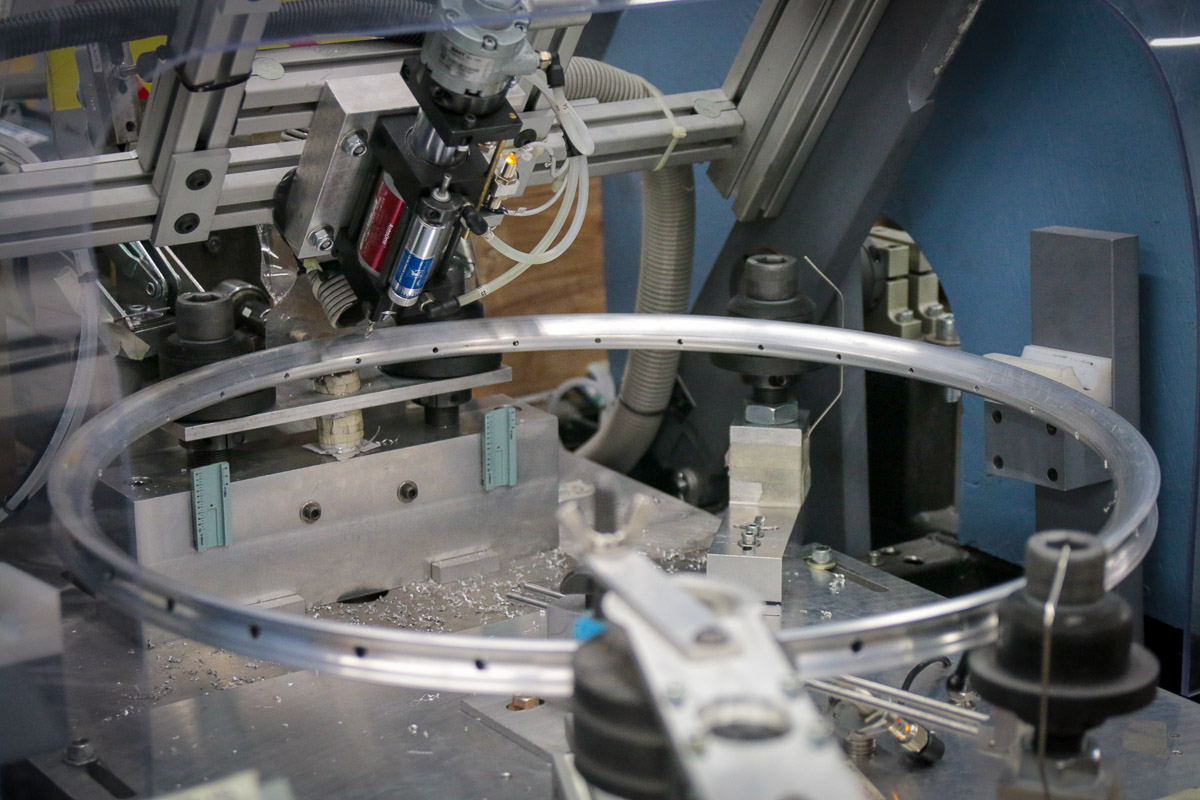

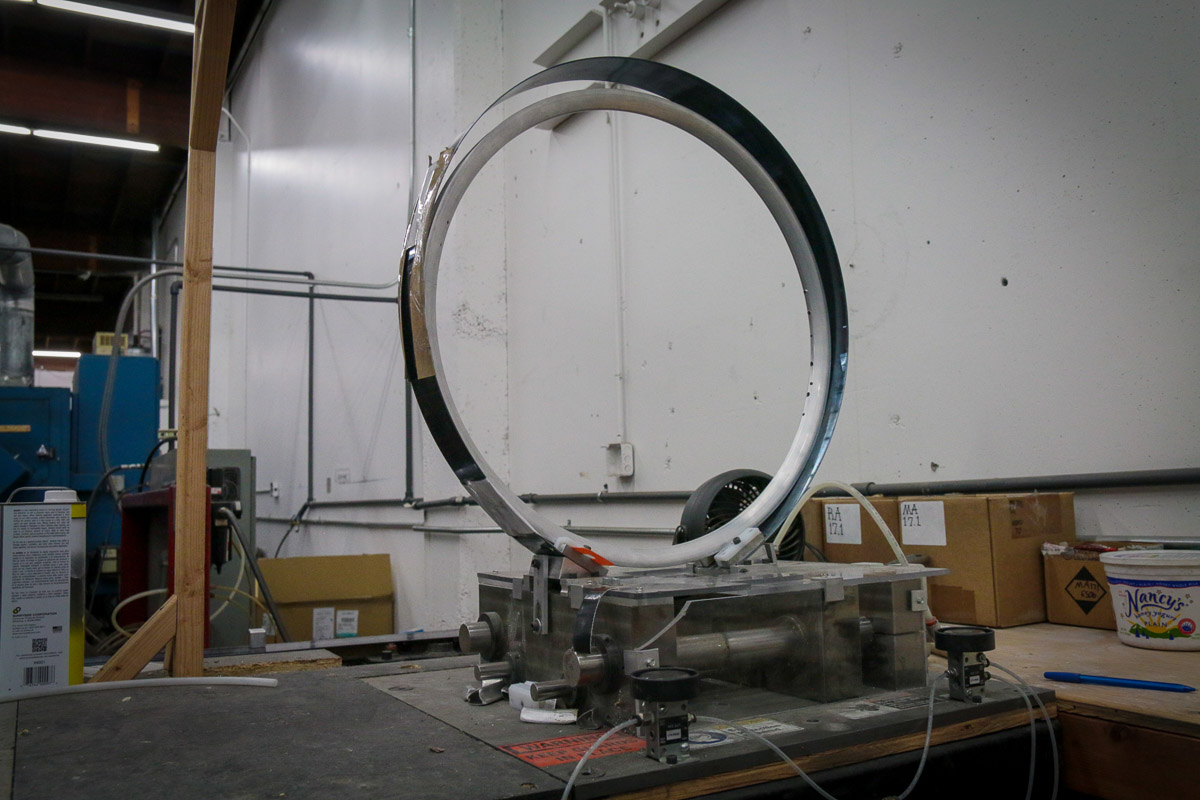

So that’s exactly what they’re doing. Starting with the same extrusions as the Rolf Prima aluminum rims, Astral is simply adding a different lacing pattern. The Astral concept has been in the works for Rolf Prima since 2011, but they finally feel like they have the space and the people to make it work. It wasn’t until 2014 that Rolf started making aluminum rims in Eugene, and Brian admits that it took a long time to get the process just right. When dealing with aluminum rims there are a lot of variables to contend with from the straightness of the extrusion that comes from a supplier in Arizona, to the rim diameter, the cut, the brake track machining, and the drilling. Not to mention heat treating and finishing. That’s led Rolf to design some of their own tools like the spoke drilling machine above which was completely built in house.

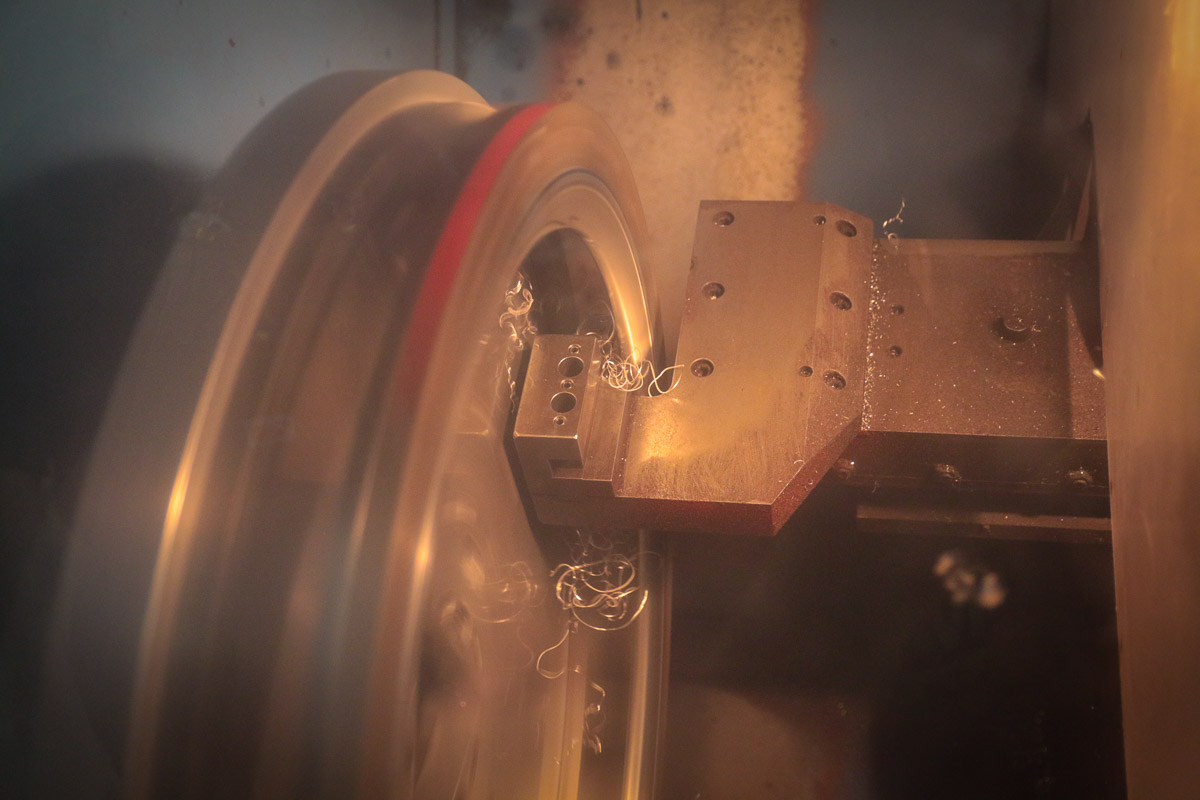

Everything Rolf and Astral does is meant to provide the most consistent and precise rim dimensions possible. That’s why all Rolf and Astral aluminum rims that have a brake track where both sides are machined at the same time. This ensures that both sides are perfectly parallel. Ever had a rim that shuddered when braking no matter how the brake was adjusted? Brian mentioned that this could be a result of unparallel brake tracks.

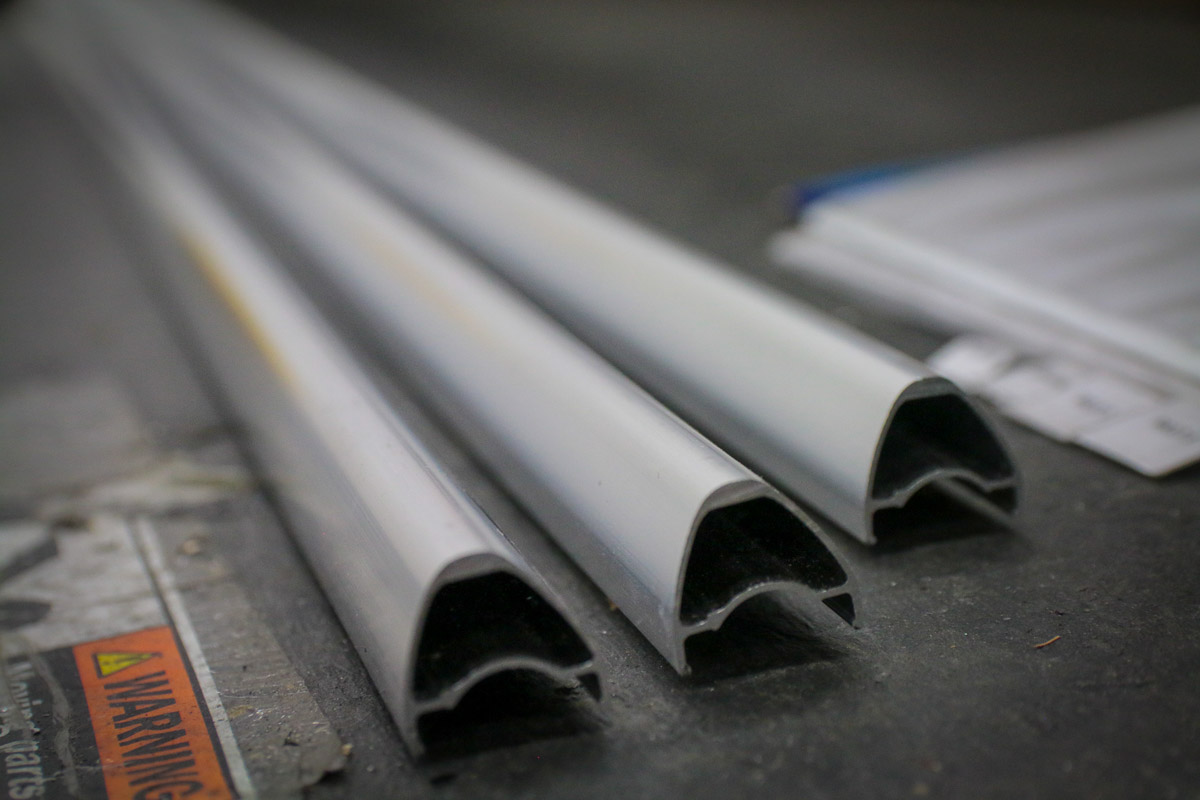

Rims start as 14ft extrusions that will end up making two rims. If you’re wondering about the price of Astral rims, consider this: the cost of just the raw material is about the same cost as a finished rim from Taiwan. Clearly, Rolf is not doing this to compete on price – but quality.

In order to dial in the process, Rolf’s Manufacturing Engineer Willy Reen redesigned their whole process a year ago which has increased precision, repeatability, and reigned in time and costs. Spitting material out of the roller and the saw is the easy part, Brian says it’s the last 3% to get it right that was the hardest part.

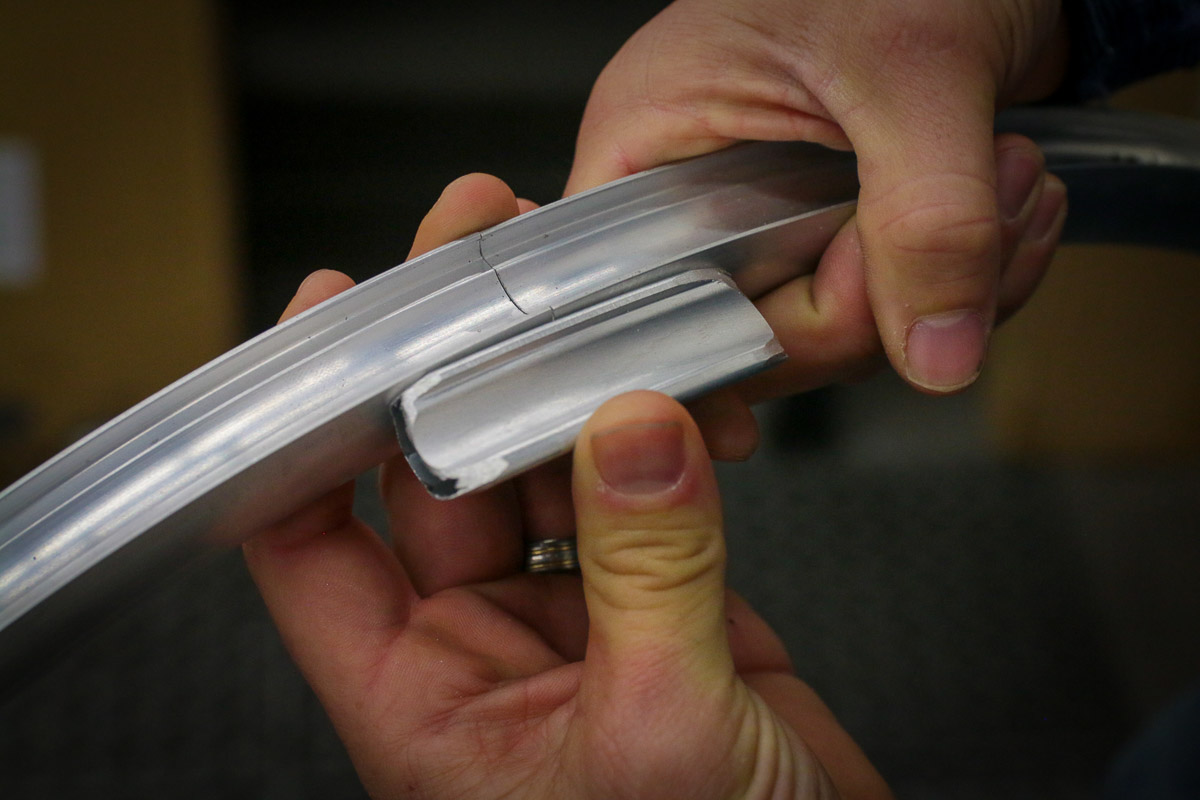

Rolf and Astral rims are also all made with sleeved joints rather than welded. It’s not that Rolf can’t weld the rims. In fact they have all of the equipment necessary sitting shrink wrapped on pallets in their warehouse. Stating that sleeving or welding are certainly the best ways to go about it, Rolf refrains from welding their rims because it adds a ton of heat to a very small zone on the rim which then becomes the weakest part of the rim – and you still have to sleeve it. By only sleeving it, the joint then becomes the strongest part of the rim – as long as it’s done right. Rolf ensures that the joint is perfectly flush, and super clean with the joint deburred, abraded, and then cleaned with acetone to make sure the epoxy sets properly. It’s important to point out though that the epoxy is just for quietness and not structural. According to Rolf the rims could be joined with just the sleeve only and they’d be structurally sound with a tight fit, but the epoxy guarantees the joint is silent in the long run.

As for the additional weight of the sleeve? It’s opposite of the valve, so it works out in the end.

Just as important as the building of the rim, Rolf performs the same extensive testing on Astral rims in house as well. From their fatigue tester which was built in partnership with Michigan Tech that can perform ISO fatigue testing and brake track heat testing (and go way past ISO standards), to impact testing, lateral stiffness, and spoke pull through testing, Astral rims are put through the wringer.

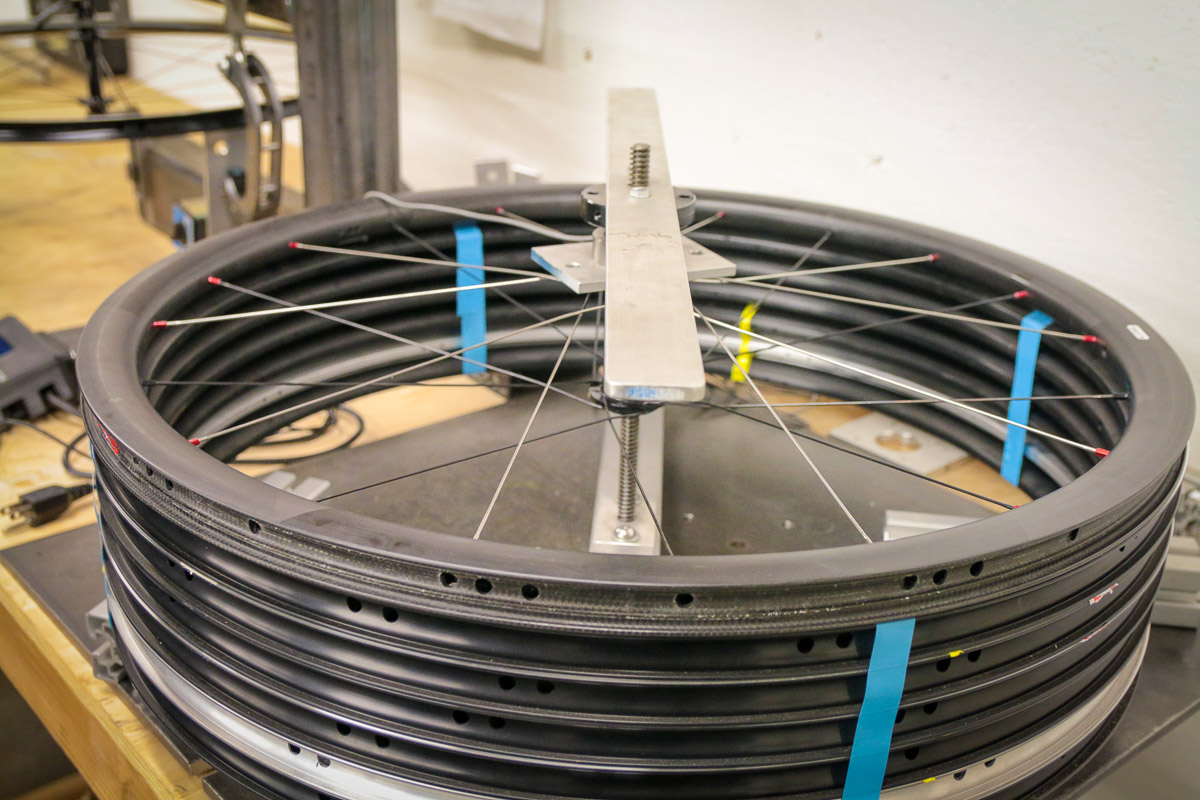

With all the testing in house, it’s enabled Rolf to test the exact same rim with the same number of spokes, with one drilled traditional and one drilled paired. Both wheels test just as well with the exception of the paired spoke rim offering better lateral stiffness for the same number of spokes, or the ability to build the same lateral stiffness with fewer spokes than a traditional wheel. Rolf also took the opportunity to show the difference between paired and non-paired designs in terms of spoke failure. By completely detensioning a single spoke on both wheels above, with the same rim, same number of spokes, and same hub, we were able to see that there was a negligible 0.03″ difference in lateral run out between the two.

But that doesn’t mean that consumers don’t still want traditional lacing, which is why Astral exists. They are the exact same rims that Rolf Prima offers as paired spoke builds, but with traditional lacing patterns. At the moment, each Astral rim has a corresponding rim in the Rolf Catalog though Rolf has the ability to make custom rims if say, a bike company wanted their own design and enough of them to make it worthwhile.

Rolf/Astral was still in the early stages of the roll out so they didn’t have all of the rims on hand during our visit and many of the graphics were still samples rather than finished production. But we were able to get a look at some of the first runs.

Every single one of the Astral rims is tubeless ready including their top level Prevail 700c carbon clincher. They call it Tubeless Easy which means you should be able to seat tubeless tires with a floor or even a hand pump.

One of their carbon rims that are made in Washington by an unspecified aircraft company, the Prevail is meant for rim brakes and is available in 20 or 24 hole traditional drillings. Measuring 33mm deep and 17.5/24.5mm internal/external, the claimed weight is 410g and it sells for $900 a piece. There’s also the option custom colored decals if you choose.

The Veil is the corresponding 700c disc brake rim which not made in the U.S. Measuring 32mm deep and 19/27mm internal/external, the rim also comes in a 410g and costs $650 and 24 or 28h drillings.

The Wanderlust is more of an all purpose road rim with an aluminum build and 700c or 650b sizes. Offered in 24, 28, or 32 hole drillings, the rim measures 23mm deep, 21/25mm int/ext and comes in at 425/450g. Like their other aluminum rims, you can get the Wanderlust in custom powercoat or ceramic coatings for an additional $150 (with custom decal colors as well) or just custom decals for $40. Otherwise, the stock rim will set you back $135.

Additionally, Astral will offer the lightweight and aero Radiant and Solstice in both rim and disc brake models, plus the Leviathan which is naturally meant for Clydesdale or tandem builds. Hollywood and the Jester offer carbon profiles for offroad use.

For the moment, Astral will only be available as rim only, though complete builds are always a possibility in the future since Rolf Already has the infrastructure. More on that in the full factory tour coming soon!