Previewed earlier this year, Tennessee-based Predator Cycling is working on a new custom carbon RF20 disc brake aero road bike, entirely made to order in the US. Using Autodesk Fusion 360 generative software to virtually optimize the structure & aerodynamics of the design, Predator says they have created “the most efficient frame on the road”.

Predator RF20 custom, US-made carbon aero road bike

Having built everything from fully-custom aero ti pursuit bikes, aluminum cruisers & carbon cross bike over the last 15 years, in addition to cockpits & carbon repairs, Predator Cycling is dialing back their frame production to focus on one product – the RF20 aero road bike.

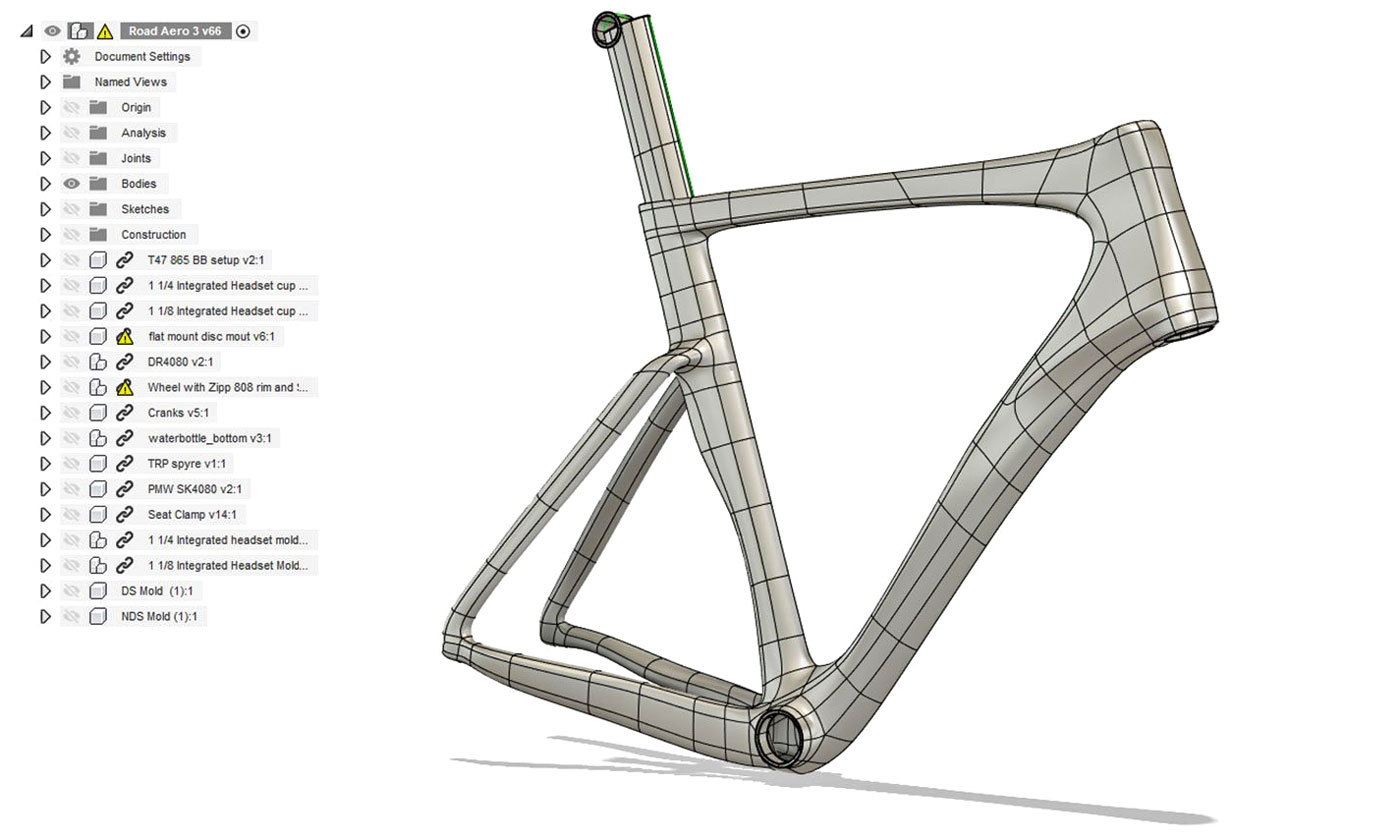

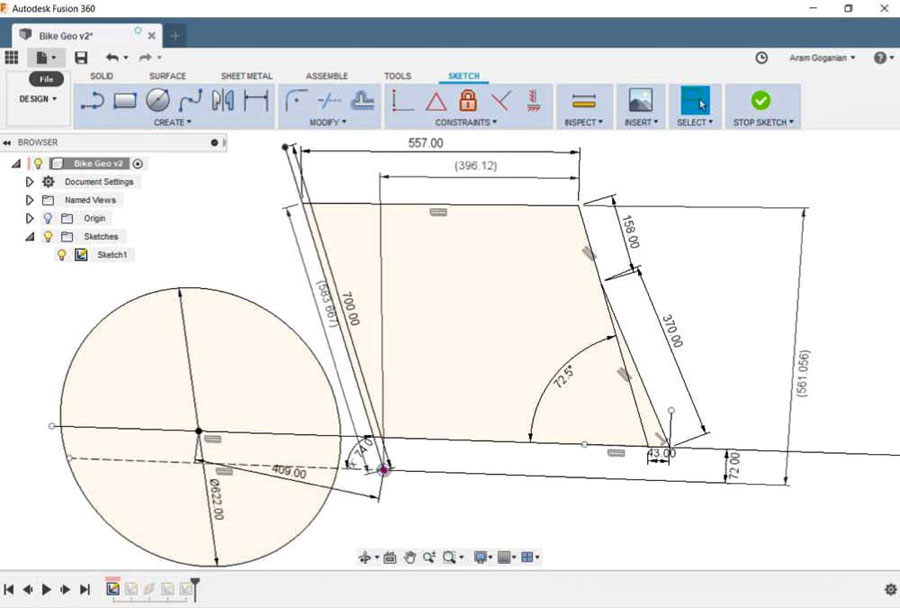

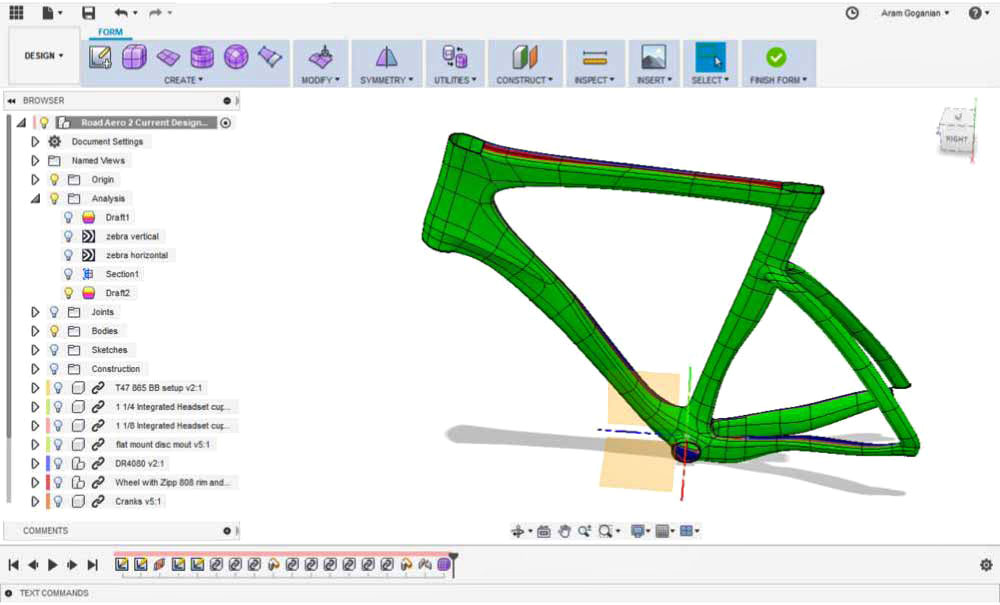

Using Autodesk’s powerful Fusion 360 generative design software, Predator has created a modern aerodynamic disc brake road bike frameset that they can customize to each buyer.

Custom carbon development

The Predator RF20 aero road bike still seems to be a project, as we’ve only seen documentation of one complete bike as a proof-of-concept. But the concept has piqued our interest.

Leveraging Predator custom carbon experience, the RF20 was completely designed & developed virtually – from aerodynamics, to force-optimized tubing profiles & individual elements, to carbon ply layups, to structural integrity testing.

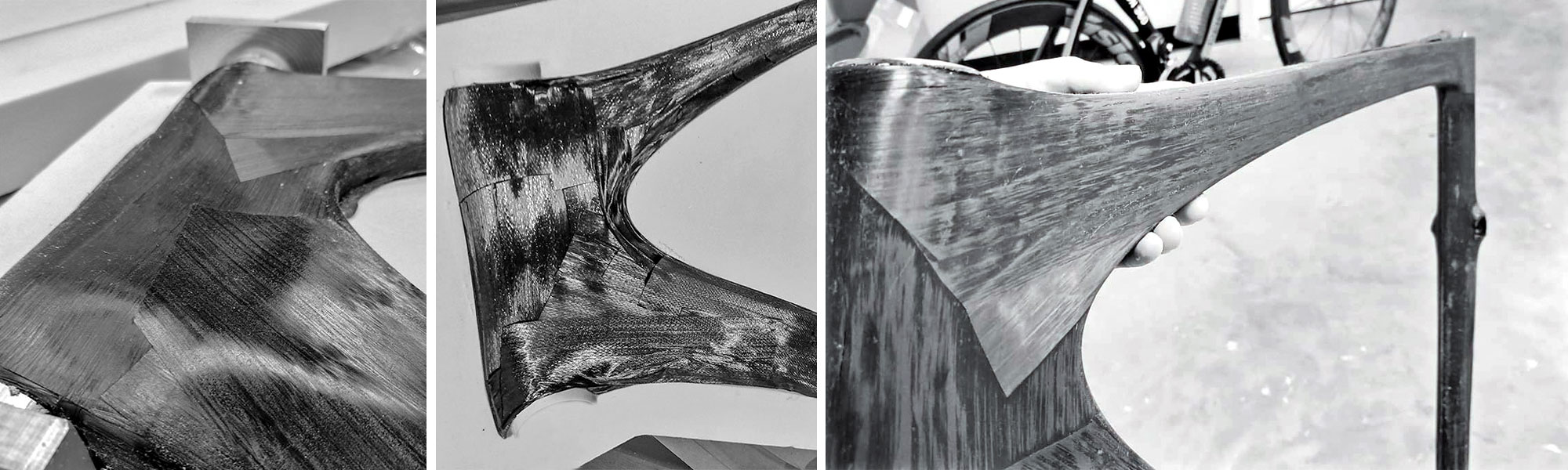

From that point, Predator 3D-prints & CNC-machines their own molds & bladders in-house, just outside of Nashville, TN. Laying up the RF20 by hand, one-at-a-time – Predator creates the frame from a one-piece monocoque front triangle, mated to separately molded chainstays, seatstays, dropouts, and their own seatpost.

Tech details

The complete details remain quite thin for a bike at this price point. But that can possibly be chalked up to the fact that Predator hand crafts each bike specifically for the buyer, giving them the chance for further customization – with custom molds possible for every frame.

What we do know is that the RF20 has a sleek aero-optimized profile with minimized frontal area, including an hourglass headtube for the tapered 1.125-1.5″ fork. Its frame shaping is quite similar to many modern aero road bikes, with a horizontal toptube, deep aero seatpost with a hidden clamp, dropped seatstays, and a rear wheel cutout.

The RF20 does however have a slightly more organic shape, with the downtube pulled back from the front wheel, and narrow fork spacing.

The bike is disc brake only, featuring flat mount calipers and 12mm thru-axles. It also gets a T47 threaded bottom bracket with an 86.5mm wide shell for max stiffness.

Predator does not specifically define the RF20’s cable routing, but complete bikes are only available with electronic groupsets.

Predator RF20 – Pricing, options & availability

Predator Cycling says they have been facing pandemic supply chain delays throughout the year, but are still accepting pre-orders for the new RF20 which they expect to be able to deliver in early 2021. Current lead time is claimed at 8-12 weeks, putting likely delivery into late March or April of the coming year. The custom RF20 is available as a frameset of frame, fork, seatpost & headset for $5250 with standard geometry in five sizes. Fully custom geometry adds an extra $1500.

Or standard complete bikes start at just under $9000 with a Ultegra Di2 build. A discount of 10% off either option is being offered now for all pre-orders, as Predator’s “production preparation continues in full swing”.