In a Press Release published by Outdoor Sportswire, W. L. Gore & Associates (Gore) announced its plans to introduce two new 2-layer Gore-Tex Laminates with Bionic textile made from plastic waste partially collected from coastal environments. The new PFC-free Laminates are intended to be used in waterproof clothing, with the first jackets to be sold by Patagonia in Autumn/Winter of 2023.

Gore-Tex Laminates with Bionic Textile

The announcement follows news that Gore Shakedry is to be discontinued, something that will come as a disappointment to many fans of the industry-leading waterproof fabric. It is so impressively waterproof due its use of a chemical called Perfluorooctanoic Acid, a member of a group of chemicals referred to as “PFCs of Environmental Concern” set to be banned in the European Union. It is a chemical that Gore Fabrics Division, as well as many other outdoor clothing manufacturers, have committed to being free of.

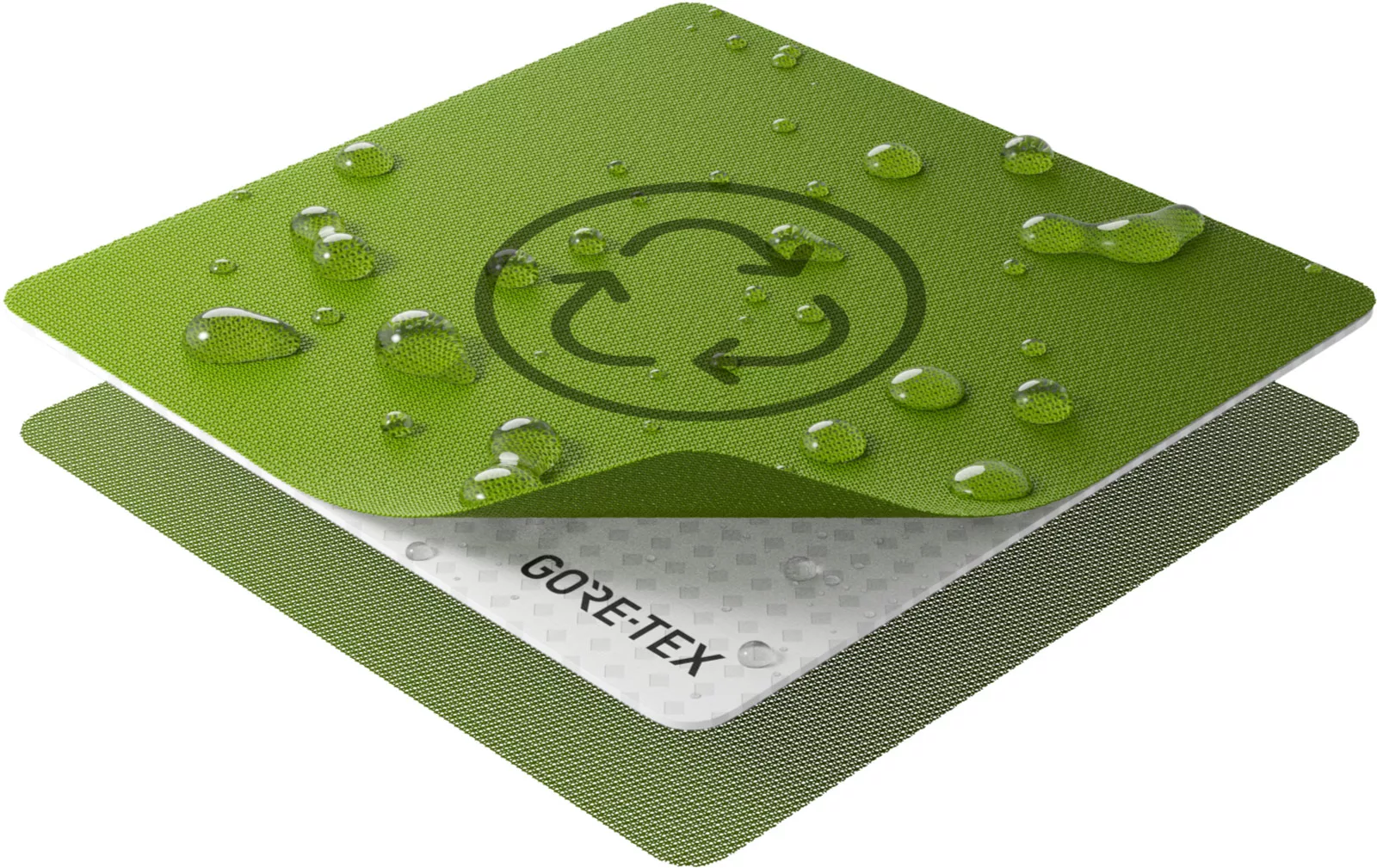

Hence, the development of new 2-layer Gore-Tex Laminates set to be used in the brand’s coming waterproof clothing that will be covered by their renowned GUARANTEED TO KEEP YOU DRY Promise. The Gore-Tex Laminates are constructed with their PFC-Free ePE membrane announced last year.

The latest news surrounding the durably waterproof, windproof and breathable ePE membrane is that it will be made from 100% recycled Bionic polyester textile, half of which is made from plastic waste collected from Bionic’s operations in coastal communities, and half of which is made from recycled plastics from other municipal collections. All of the material is certified according to Global Recycled Standard (GRS).

The Press Release reads, “Gore has collaborated with the Bionic team to support their mission of reducing ocean plastic through community engagement by investing in their plastic recovery and sorting facility in Cóbano, Costa Rica. Through this effort, the operation collects plastic waste so it does not end up in the ocean. Sorted plastic waste is then turned into materials used in the textile component of these new GORE-TEX Laminates”.

Erik Schrej, W. L. Gore & Associates Consumer Garments Product Specialist says, “From a performance perspective these textiles are very similar to laminates made with equivalent (denier, laminate construction, etc.) recycled textiles. The uniqueness of these laminates is the mission they support, allowing the brands we work with, and ultimately consumers, to directly support the environmental community efforts that Bionic initiated.

The details of the process start in the local community of Cobano, Costa Rica where the plastic is recovered from the coastal environment. In Costa Rica, Bionic collects, sorts, and chops the plastic waste. The chopped plastic is then sent to Gore’s certified textile manufacturer where this plastic is turned into yarn, which is then woven into a finished textile. The textile is then sent to Gore for lamination to our new innovative ePE membrane and application of our best in class PFC Free DWR. The end result is a 2-layer laminate Gore sells to our brand partners.

The two new 2-layer GORE-TEX laminates with BIONIC recycled textile meet the same performance standards as the other 2-layer GORE-TEX laminates in the collection – all are durably waterproof, windproof, and breathable and are covered by Gore’s GUARANTEED TO KEEP YOU DRY Promise. These laminates are used to make 2-layer lined and insulated garments made for general outdoor and lifestyle use. Targeted activities for these end-uses can include outdoor pursuits like hiking and lift-served ski to everyday use like commuting”.

“Great partnerships are built on shared vision and passion, complementary expertise and the collaborative skills and discipline to see things through. This innovative project between Patagonia, Gore, and Bionic represents that shared vision and what the future can, and should, look like for high performance outdoor protection – same waterproof performance, no forever chemistries, and radically recycled NorthStar material inputs,” said Mark Little, Global Product Director, Men’s Life Outdoors for Patagonia.

“This launch is the culmination of years of close collaboration with Gore, the development of novel processing techniques, and the creation of an entirely new and traceable supply chain. Raising the profile of BIONIC textiles to the standards of the GORE-TEX Brand has been the best kind of challenge and resulted in a truly special material that has found a perfect home at Patagonia, with its long history of high-performance innovation and stewardship,” said Tim Coombs, Bionic co-founder.