Industry Nine is introducing a new hollow-walled rim on its flagship aluminum wheelset for enduro riding; the EN300 Hydra. Built up the Industry Nine’s Hydra Hubset, the new EN300 Wheelsets are around 20g heavier than the outgoing EN305 equivalent, but in-house impact testing demonstrates the rim’s superior strength. Here’s more.

Industry Nine EN300

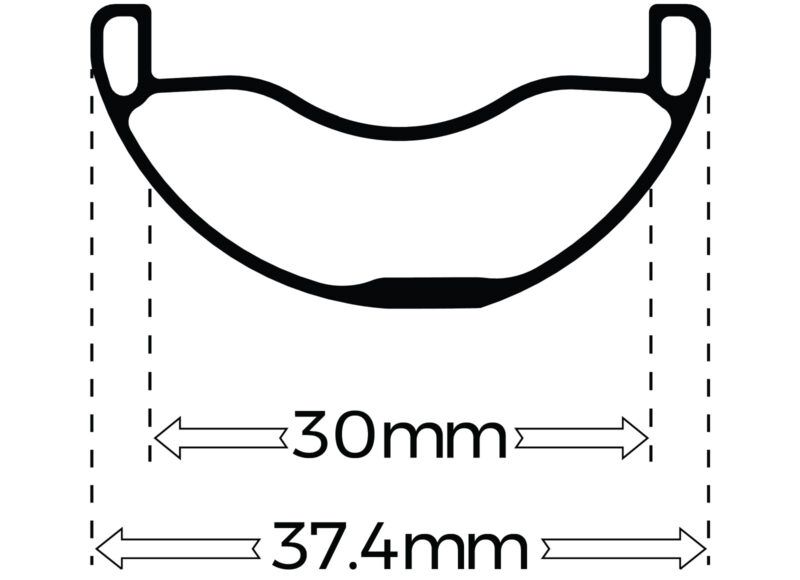

Industry Nine’s rims have been steadily growing in width over the last few years, and that trend doesn’t end with the new EN300 Alloy Rim. It has an internal width of 30mm, a dimension that most of the industry appears to have settled on for tires in the 2.3″ to 2.6″ range. Meanwhile, the external width grows to 37.6mm in a bid to both reduce bead shelf and bead wall deformation during impacts, and to reduce the risk of pinch flats.

The real new-ness here cannot be seen with the naked eye. While the EN305 featured a solid bead wall, the new EN300 aluminum rim gets a hollow bead wall extrusion, said to help the rim shrug off impacts while maintaining a competitive system weight. The rim depth remains relatively shallow at 18.5mm, with an asymmetric bed profile that allows for more balanced spoke tensions between the DS and NDS.

Industry Nine’s in-house impact testing quantified just how much stronger the EN300 is as compared to the EN305. Numbers in the table below pertain to the percentage improvement in deformation of the EN300 over the EN305.

“We set a number of test wheels up in a vertical impact testing fixture and impacted with a sliding anvil and measured the rim damage from increasingly rising heights. We used a smooth 29” tire for tread uniformity that a regular MTB tire might not provide. After the test was conducted, we measured the deformation in a few different rim locations – the movement that the bead wall defected towards the rim center, and the deformation we measured on the bead shelf, where the base of the tire bead would sit against the rim. The results we shared are our results from testing the EN305v3 against the EN300. We saw improvement on both “minor impact events” and “severe impact events” in the bead wall and bead shelf deformations on the EN300 over the EN305″ – David Thomas, Industry Nine.

| Moderate Impact | Severe Impact | |

| Bead Shelf Deformation | 41% | 28% |

| Bead Wall Deformation | 22% | 35% |

The EN300 will be sold as a complete wheelset only, laced up with 32 spokes to the 6-Bolt Hydra Hubset. Claimed weight for the complete wheelset with XD freehub is 1,870g for the 29″, and 1,800g for the 27.5″.

Pricing & Availability

Pricing for the Industry Nine EN300 Wheelset starts at $1430 USD, with black spokes and hubs, and the choice of HG, XD or MicroSpline Freehubs. Part with an extra $50 USD to get coloured spokes, an extra $150 USD to get a coloured hubset, or an extra $250 USD to have your spokes in multiple different colors. In Europe, pricing starts at 1,535 EUR.

The 29″ Wheelset is available to order now in Standard, Boost, SuperBoost, and Single Speed hubsets. The 27.5″ wheels are to be ready to ship by June, with MX Wheelsets also available thereafter, though pre-orders are open now. Industry Nine’s warranty policy on this wheelset extends to two years for the original owner only, and covers manufacturing defects only – not any damage caused during riding.