Last fall, Bikerumor previewed a wide selection of chainrings and derailleur pulleys from a Ukrainian company called KA Engineering. Since then I was given the chance to test out their titanium chainring & aluminum pulley wheels, which have endured this summer with hardly a scratch to show.

Read on and we’ll toss a few parts on the scale, and fill you in on how they performed.

KA offers a wide range of spiderless chainrings to fit most popular crank spindles. Buyers can choose between ti or aluminum, and round or oval shapes. Regardless of model and tooth count, KA’s spiderless ti rings sell for 179€ while the aluminum models range from 54-60€.

The Ti chainrings are made from aerospace-grade TI-6AL-4V. Weights will vary depending on model and size, but my round titanium 28t non-Boost Cinch ring hit the scale at 67g.

The aluminum rings are made from 7075-T651 alloy, and offer tons of anodized color options. This beautiful blue 30t ring weighs just 53g.

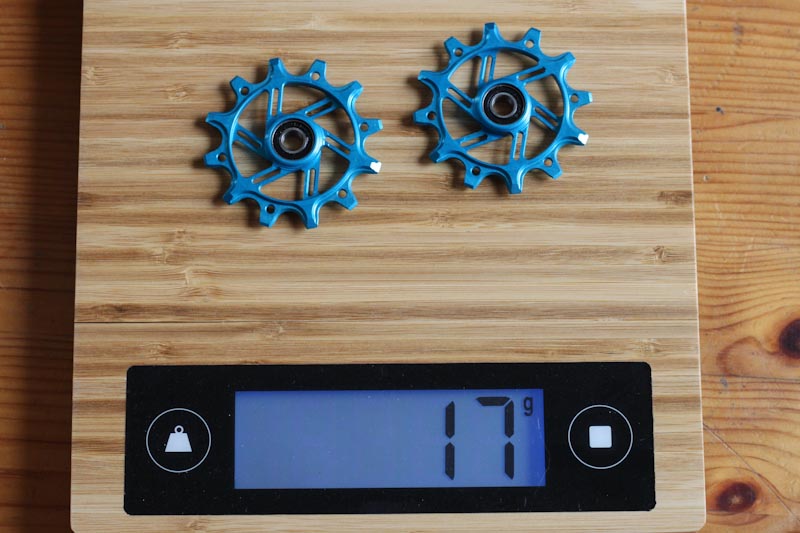

The company also produces sealed-bearing pulley wheels in both ti and aluminum. The pulleys feature narrow/wide teeth but the profile is different from the Sharktooth design used on KA’s chainrings. Aluminum prices range from 40-65€, and they come in a rainbow of colors. The Ti pulleys sell for 110€ per pair.

Ride Report:

I installed KA Engineering’s components while converting/updating an old mountain bike to a 1×10 drivetrain. So a new chain, derailleur, and cassette were all put on with the chainring and pulleys. Right away I was stoked on the appearance of the colored pulleys and machined ti ring (and that ano aluminum ring too), they definitely add a little flash for your cash.

I made this upgrade in late May, so between test riding other bikes I have ridden a little over half a season with KA’s ring and pulleys (I only briefly installed the aluminum ring until the ti version arrived). At this point the ti ring is showing so little wear that if I cleaned it up nicely it could be mistaken for a brand new part.

The aluminum pulleys are also still at 95% or better. The chain has worn down some of the anodizing, but beyond that there’s only a minuscule amount of wear on the wider teeth. I did notice that the profiled teeth tend to retain a lot of dirt and grime, but in the dusty conditions I’ve had, I never experienced any issues due to excessive buildup.

For the chainrings KA has created their own narrow/wide design they call Sharktooth, in reference to their teeth’s hooked-back shape. The width profiling isn’t really complex; every second tooth gets a thicker step on both sides. The ridge between the steps gets a little grimy, but overall the chainring’s teeth stayed much cleaner than the pulley wheels.

With no proper tensioner or chainguide in place (but a clutched SRAM derailleur), I have not dropped a chain since installing the KA components. Perhaps the retention owes something to the depth of the teeth, which actually stick out above the chain (see pic above). But between that and the Sharktooth profiling, something is working.

I haven’t felt any penalty as far as drag or friction. KA’s ring and narrow/wide pulleys run just as smooth as any other drivetrain I’ve ridden. With all new components one would expect good performance, and luckily that’s all I’ve had.

One shop guy I know thought titanium might be a bit soft for chainrings, but with 1×10 or 1×11 setups the rings are so small they’re likely to avoid most trail bashing abuse. Consequently, I haven’t smacked the ti ring on anything yet, and I wouldn’t be surprised if I never do.

I’m pretty impressed with the chain retention and lack of wear on the chainring and pulleys. Since they’re also lightweight and look great on the bike, I expect to be riding them for quite some time.