Time can’t be rushed. Not only has it taken the bike brand from Grenoble, France several years to release the latest climbing bike in their Altitude series, their artisans say it takes as many as 22 hours to hand-craft each frame.

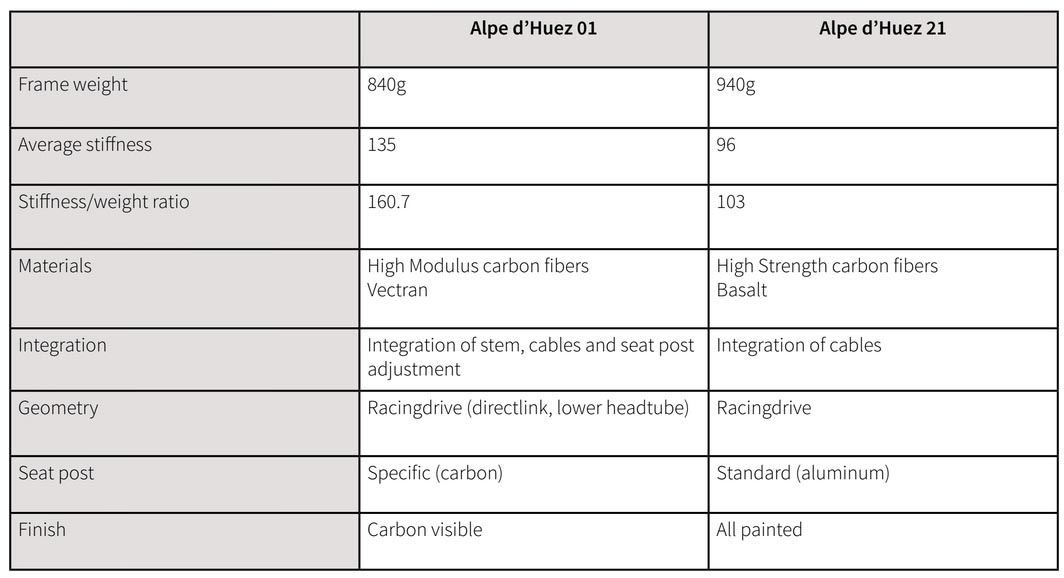

The successor to the Izon, the Alpe d’Huez is touted as the lightest frame Time has ever made. At 840 grams for an unpainted size small, it is exceptionally light. But there is more to their latest bike than a low scale weight. The proprietary carbon construction and fabrication process yields a stiffness-to-weight ratio 25% greater than the Izon.

To achieve those numbers Time starts with individually selected fibers woven on location in their factory in France. By incorporating Vectran threads into the weave, they’re able to increase strength while reducing weight and improving vibration damping. Roughly 3% of the 7,300 individual fibers used in the frame are Vectran. One of the few companies in the industry to create their own carbon in-house, they also employ a sophisticated Resin Transfer Molding (RTM) process to form their tubes.

With the carbon fiber fabric spun into soft tubular sections, the dry material is drawn over solid forms before being injected with resin. Whereas other manufacturers use internal bladders, hard forms allow for more uniform and precise distribution of resin. That translates into lower weight, greater durability, and more consistent performance attributes.

Time is not divulging the trade secrets behind their proprietary molding process, but they did disclose the basics of final construction. The forwad half of the frame is a monocoque assembly with the rear stays joined with carbon lugs. On the unpainted frames the different carbon weaves are left exposed.

The top level model in the series is the UL-Team. Fitted with ENVE wheels and Dura Ace Di2 it is slated for a limited production run of just 50 bikes. If that doesn’t put it out of reach, the $16,200 MSRP might. The frame-only O1 model sold with the elegantly simple 27.2mm seatpost carries a price of $5,150.

Available with Time’s innovative Aktiv anti-vibration fork technology, the Alp d’Huez doesn’t compromise comfort for efficiency. Inside each fork blade, positioned just above the dropouts, are two dynamic drummers tuned to absorb 30% of all transmitted vibrations. The attenuated ride reduces rider fatigue without hindering efficiency or handling performance. At only 200 grams, the weight penalty is negligible.

If the entry point of the limited edition bike is a little over your pay grade, Time achieved another all-time first with some of the least expensive bikes they have ever offered. The Alpe d’Huez 21, sold as a complete bike and named after the switchback at the base of the famous climb, starts at just $3,500.

To achieve the lower price point, the 21 foregoes the Aktiv fork, Vectran fibers in the tubing, and uses a standard headset in lieu of the integrated unit in the UL-Team and O1 frame. The resulting frame is 100g heavier, and not as stiff, but it does drop the price substantially. All three Alpe d’Huez models are available in the coming months.