Sold on the new Parlee Z-Zero GT road bike? Curious how it’s made? We swung by their Beverly, MA, headquarters to check out the new bike and get a closer look at their all-new fork, their first ever designed and manufactured in house.

While there, CEO John Harrison took us for a tour of the entire factory and their Paint Lab, and we video’d the whole thing. Here’s the full walk through, followed by more pics and details on the bike and fork…

The video above shows their factory and facilities. The pics below focus mostly on the fork, but first a few shots of the new GT and how its headtube compares to their other models.

Parlee’s current catalog consists of the RZ7 (aero road bike, on left), the new Ouray all-road bike (center, on pedestal), and the Taos gravel bike (back right).

In the foreground is the prior generation Z-Zero custom road bike platform (dark bike) and the new Z-Zero GT (white front end). The GT effectively replaces the Z-Zero and will be available in stock and custom sizes.

This one is the 25th Anniversary Edition celebrating the life and work of founder Bob Parlee. Note the gold leaf inlays and detailed painted graphics. Click any photo to enlarge.

One of the most unique features of the new GT is the slim headtube that’s still able to hide the brake hoses internally. From left to right, these are the head tubes for:

- Z-Zero GT

- Prior Z-Zero

- RZ7

- Ouray

Note how slim the GT’s is, particularly at the top. This is thanks to their new fork:

This is the finished product. Here’s what it starts out as:

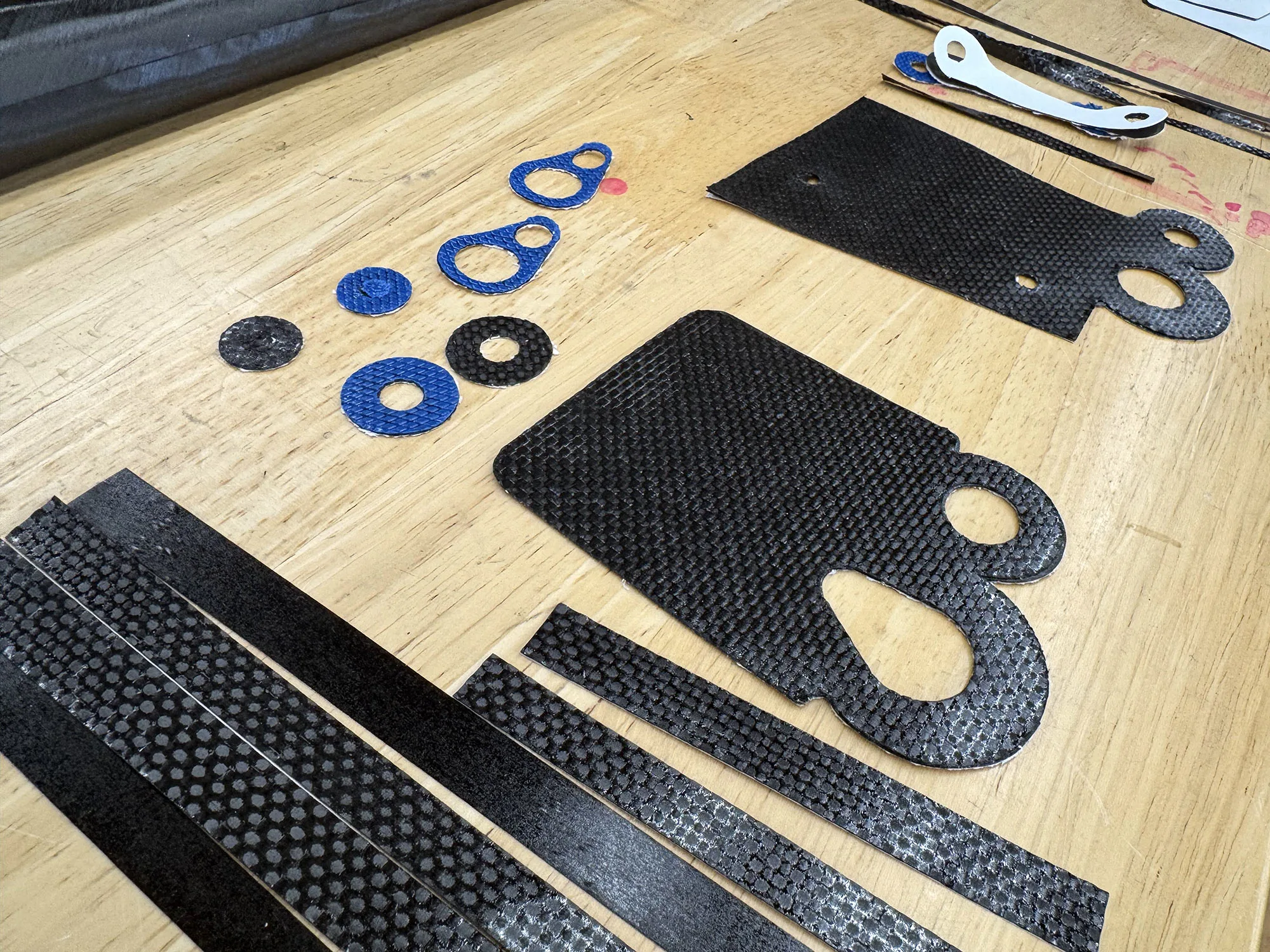

Parlee spent many months refining the layup, with hundreds of unique pieces of unidirectional and woven carbon fiber used to make a single fork. The pic above shows just some of them.

The most critical, and difficult, part is the dropouts, where most of the unique pieces are stacked and layered to make them strong enough while also delivering a comfortable ride.

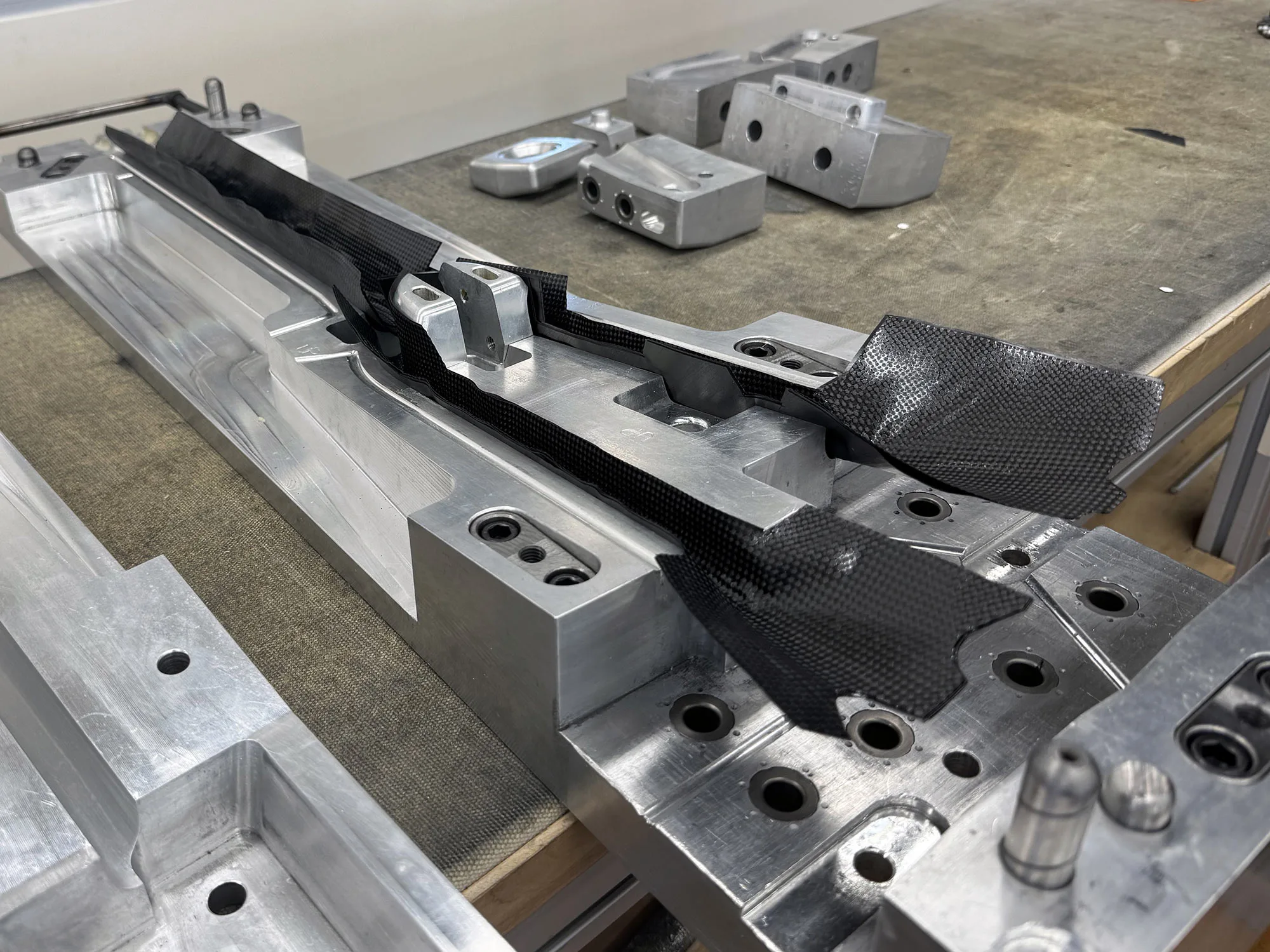

The outer layer is all UD, which is what gives the fork its smooth finish. They use hard outer molds with expandable inner molds to press the carbon against the metal during molding.

The forks come out nearly finished…just a bit of mild sanding to remove the flashing (those little wisps you see on the crown) from resin as it’s pushed out of the seams and ports.

From here, you could just wax the fork (and frames…they come out just as clean) and leave that beautiful carbon visible to all. That’s the lightest finish, and you won’t have to worry about scratches!

The most unique feature of the fork is its D-shaped steerer, which allows them to run the brake hoses into a standard-sized headset and then down into the frame. A port at the base of the steerer feeds the front brake hose down into the leg to reach the caliper.

During development, they tested different layups and sent them to a German testing facility for impact, flex, and other traits. Check the video to see some of the early flaws they caught and you’ll understand why this process is so important.

They also cut them apart to see how the carbon layered and formed during molding, allowing them to identify weak spots, folds, and other non-idea results and work those out by refining material placement and layering.

The end result is a bike and fork they say rides better than anything they’ve ever made while staying true to their classic Z-Zero aesthetic.

Hit up these links to learn more about the new Z-Zero GT and the very cool, very expensive 25th Anniversary Edition shown in this post.