The Big Three of bicycle drivetrain have been all been busy at work with updates. Will the future include faster, more precise rear shifting? Or perhaps a new method of mounting up cassettes with a 10-tooth cog? Or is the entire drivetrain as we know it heading internal? Let’s dig in.

SRAM

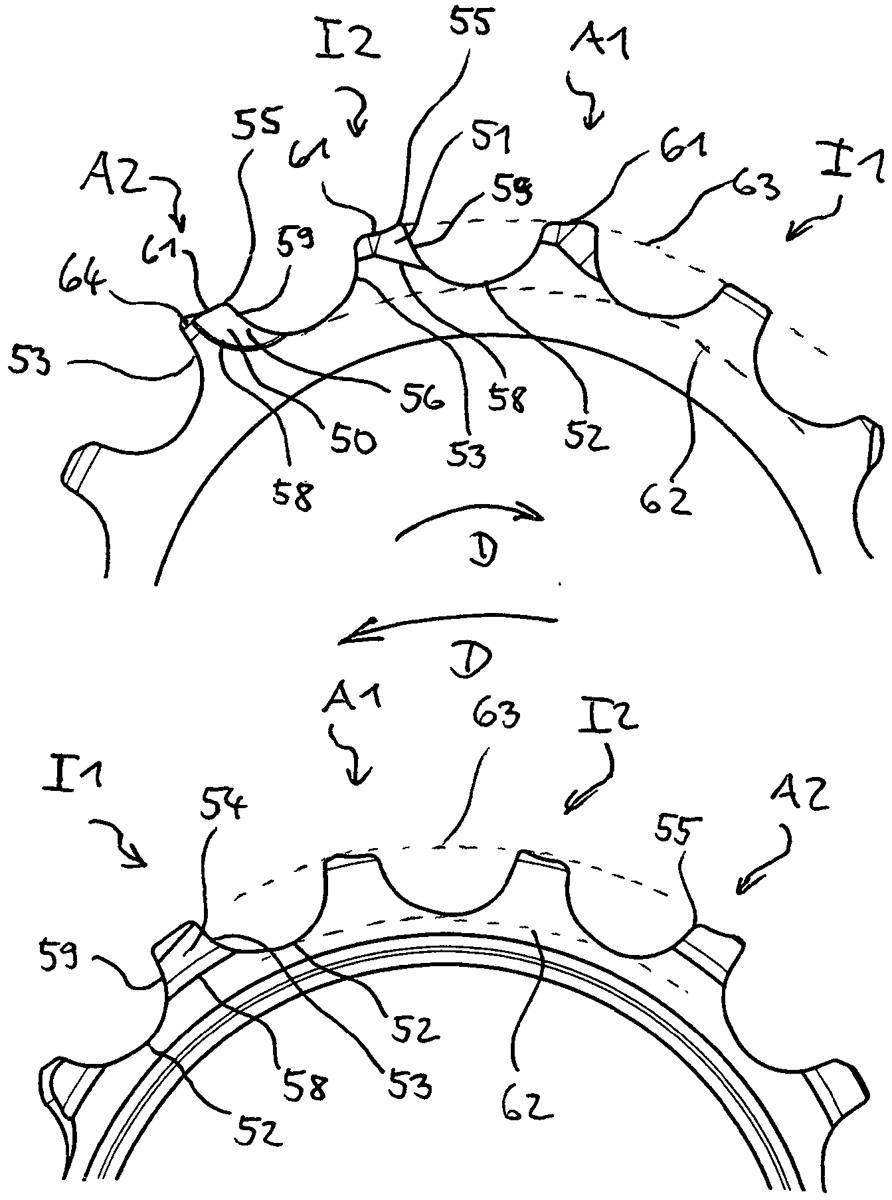

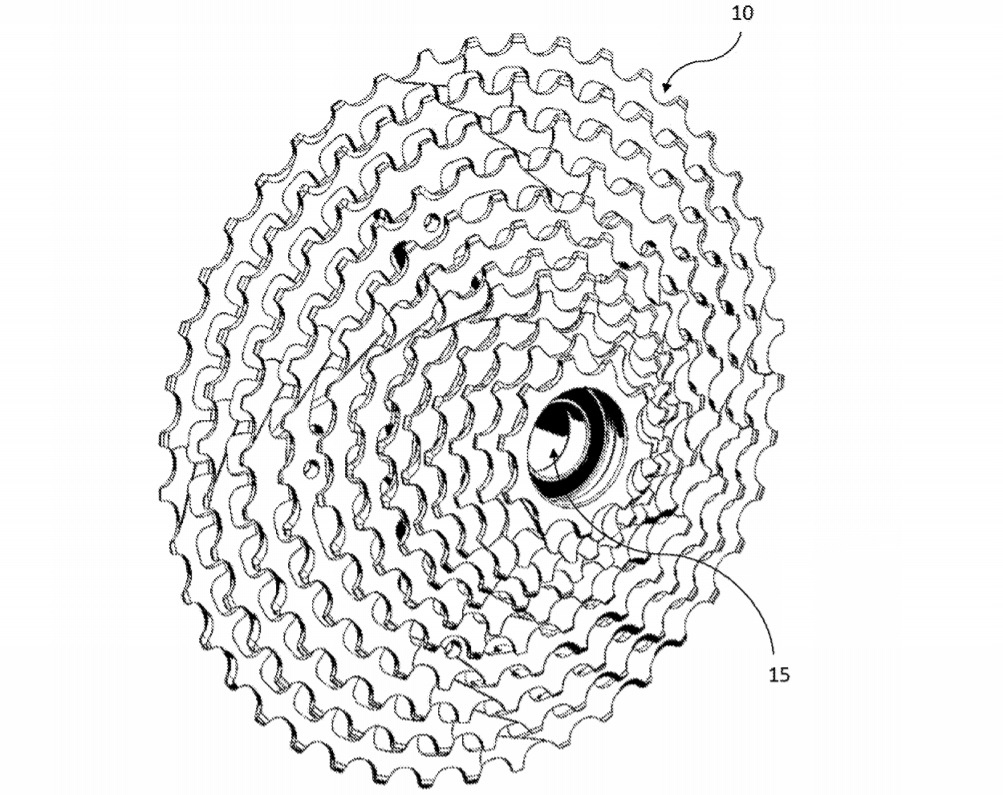

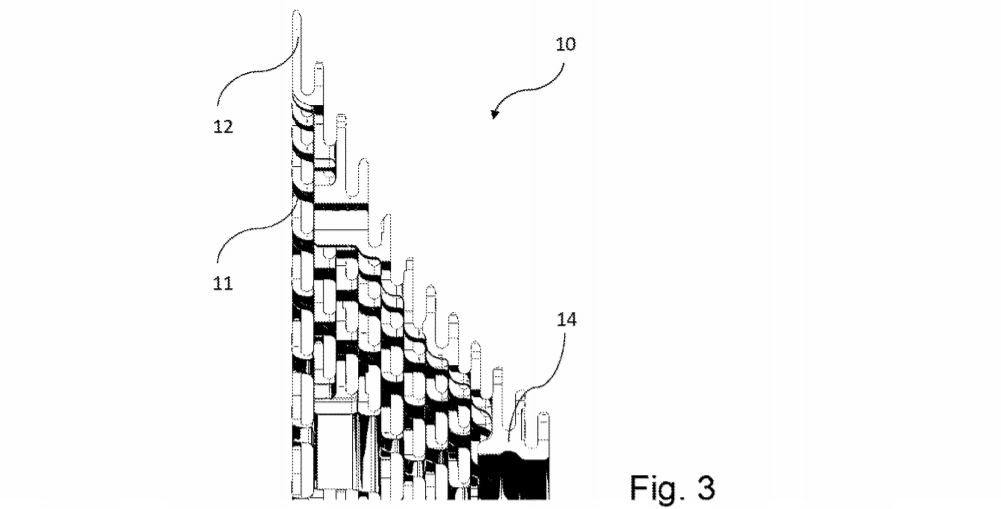

First up is SRAM, who filed a patent to further refine the shift ramps in their cassette cogs. By adding a recess on the outboard side of a tooth, shifting is improved while wear is diminished.

In addition, there is an intentional number of teeth to which the new profiling is applied:

“A particularly advantageous further development of the shift gate is obtained if elements for forming this shift gate are arranged on four directly successive teeth. These shift gate elements cooperate with immediately following the chain links, namely with an inner link member, an outer link member, another inner link member and a second outer link member, so that the chain disengaged from the larger start pinion without riding on the tooth tips.

The tip circle radius of the tooth tips on the smaller target pinion is then greater than the root circle of the tooth space on the larger start pinion with a tooth number difference of one tooth. This means that in the case of a switchover, the process of disengagement has not yet ended, and the engagement has already begun. Both processes take place simultaneously for at least a part of the time span for switching over.”

Campagnolo

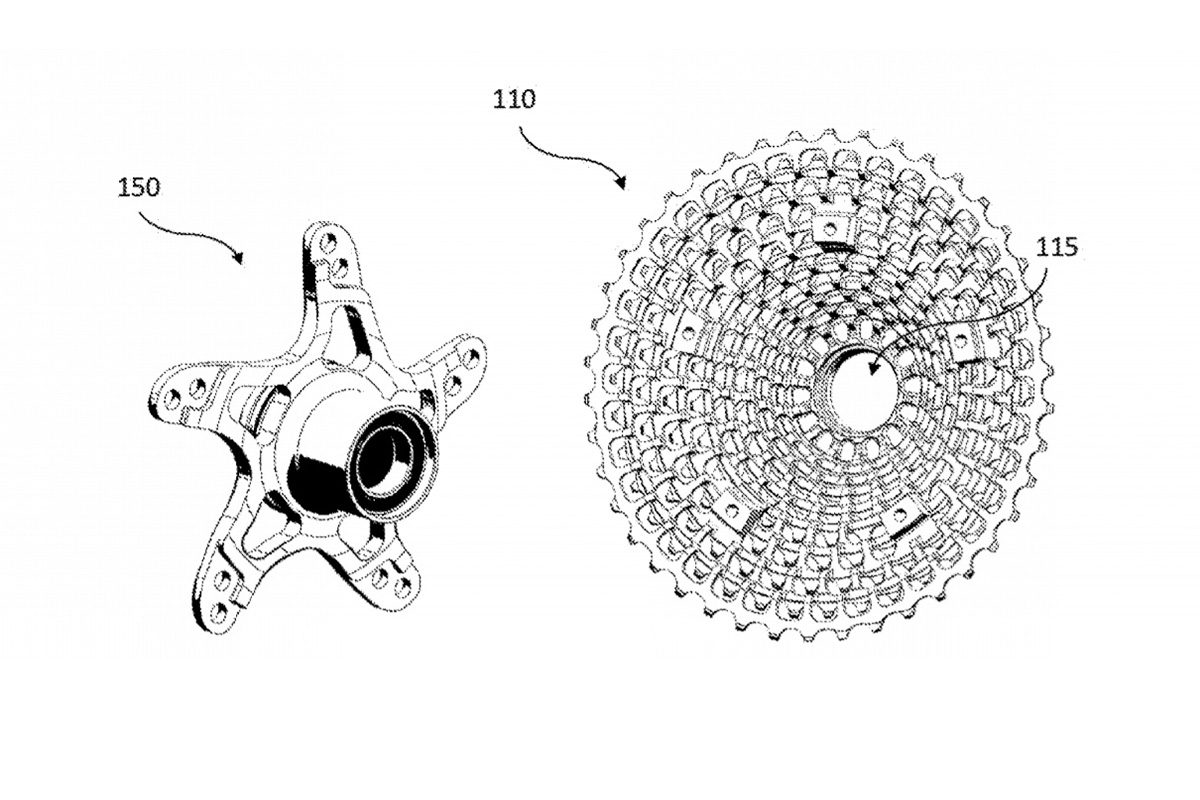

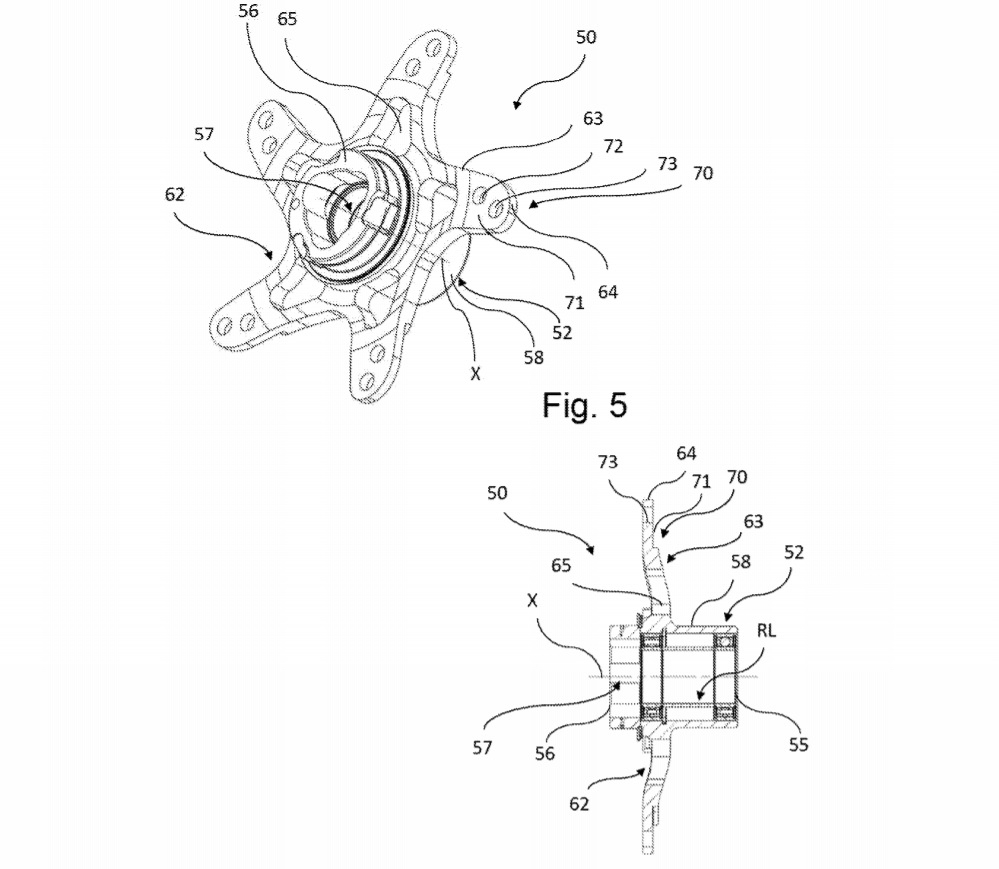

Next up is Campagnolo, who filed a patent covering an all-new cassette and cassette body for rear wheels. At first glance, this might appear to be a standard cassette with alloy cog carrier, mounted up to a standard freehub (a.k.a. cassette body). However, if you do some careful counting…

…you might notice that it has a 10-tooth small cog. Indeed, it appears that Campagnolo is finally jumping in to cogs smaller than 11… which may also suggest single chainring (1x) options in the future.

The cassette mounts up to the freehub via several attachment points, with the patent suggesting that it would be secured by some type of threaded fasteners rather than a lockring. Below, we’ve pulled out a few pertinent portions of text:

“With this cassette, the attachment to the body does not take place through a grooved profile formed on the first portion of the body, but rather through the attachment areas, arranged in a radially outer position with respect to the centering opening. Therefore, the diameter of the centering opening is not constrained by the need to transmit the pedaling torque and therefore it can be less than what is normally provided; consequently, the first sprocket is not constrained to a minimum diameter and therefore its number of teeth can also be very low, for example 10, 9 or even less.

Furthermore, since the attachment of the cassette to the body takes place in a position far from the axis of the cassette, therefore with a favorably large arm, the stresses transmitted between cassette and body are less, for the same torque transmitted. This advantage can make it possible to reduce the dimensions of the parts that transmit the stresses, or also to select lighter materials even if they are weaker.”

In addition, Campagnolo suggests that the cassette itself should ideally be machined from a single piece for optimal performance:

“Preferably, the sprockets of the cassette are formed from a single piece, suitably machined. For the purposes of the invention, as stated, it is necessary for the sprockets to be fixedly connected to one another, i.e. they for a monolithic assembly; this feature can also be obtained by joining together the sprockets, through whatever suitable means, like for example screws, couplings, gluing, welding; however, if the cassette is obtained from a single suitably shaped piece, it is possible to obtain the maximum rigidity and strength for the same weight, or lower weight for the same strength.”

Shimano

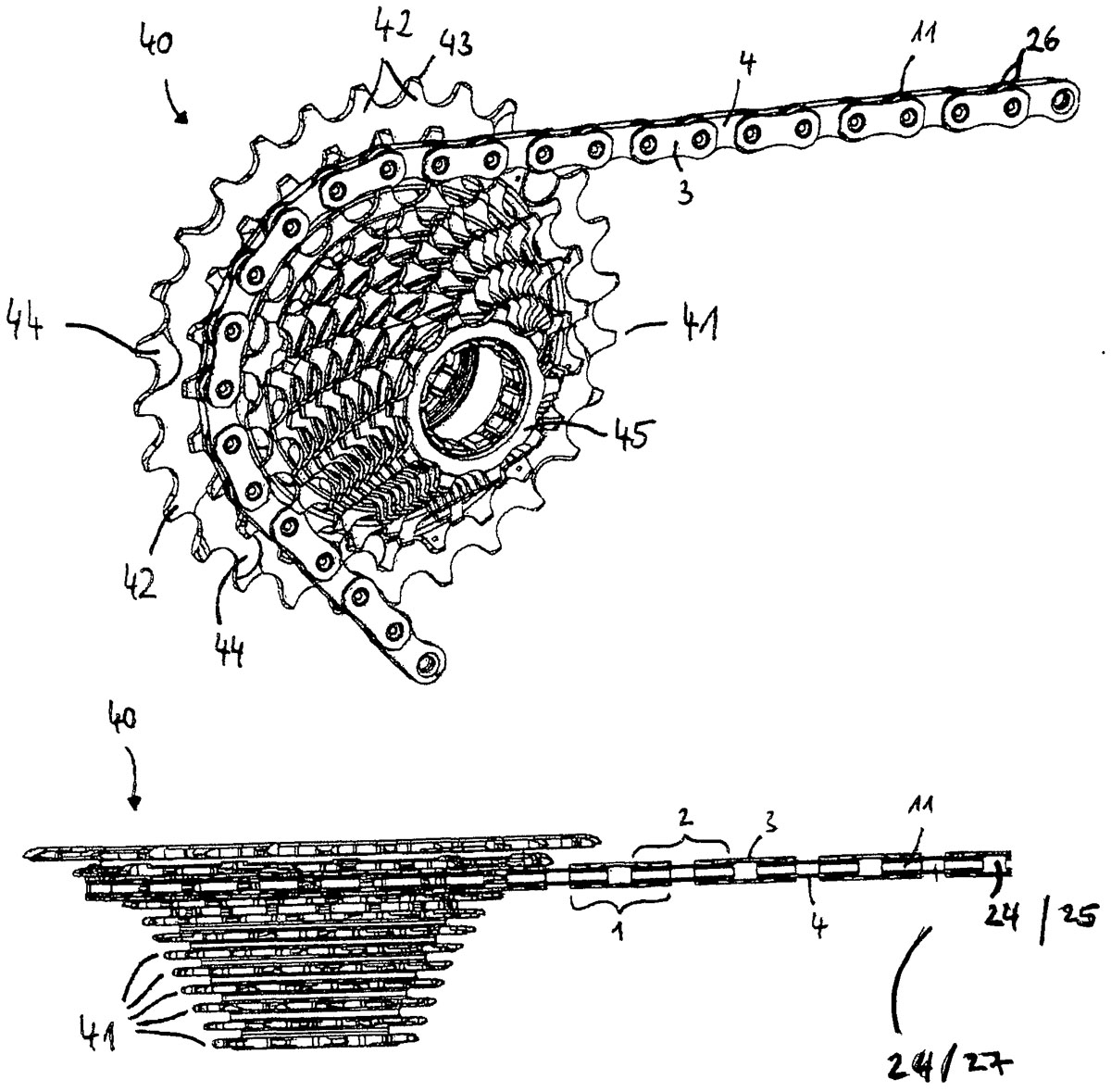

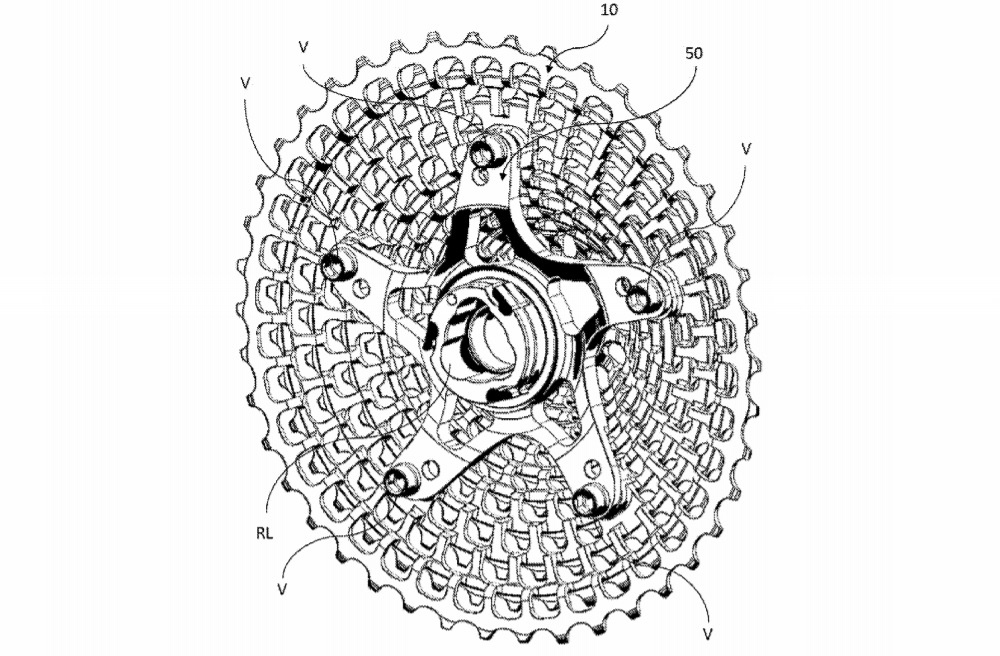

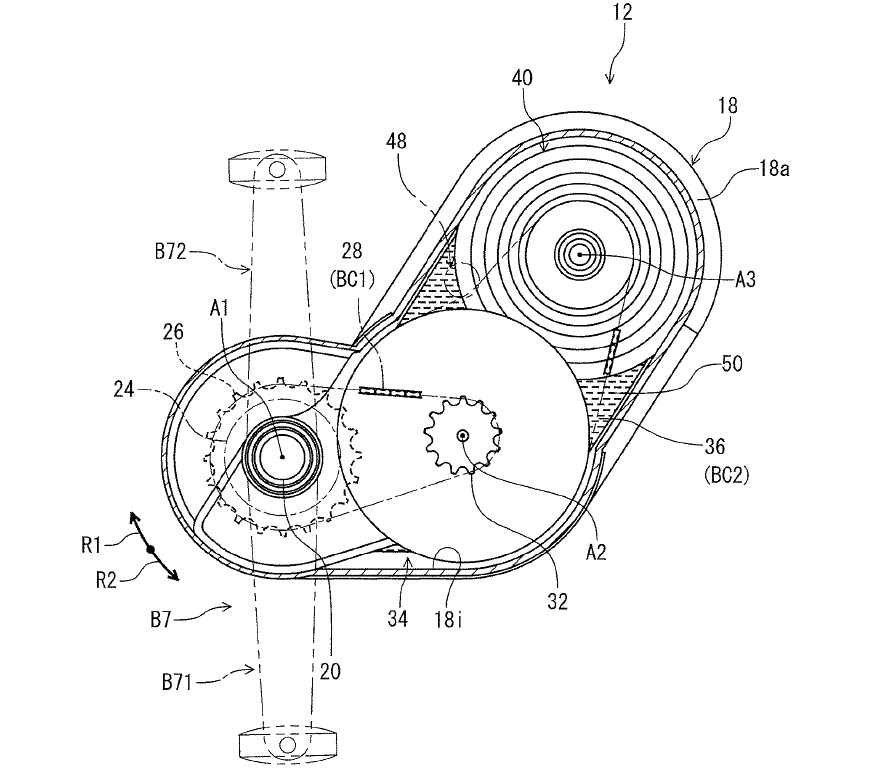

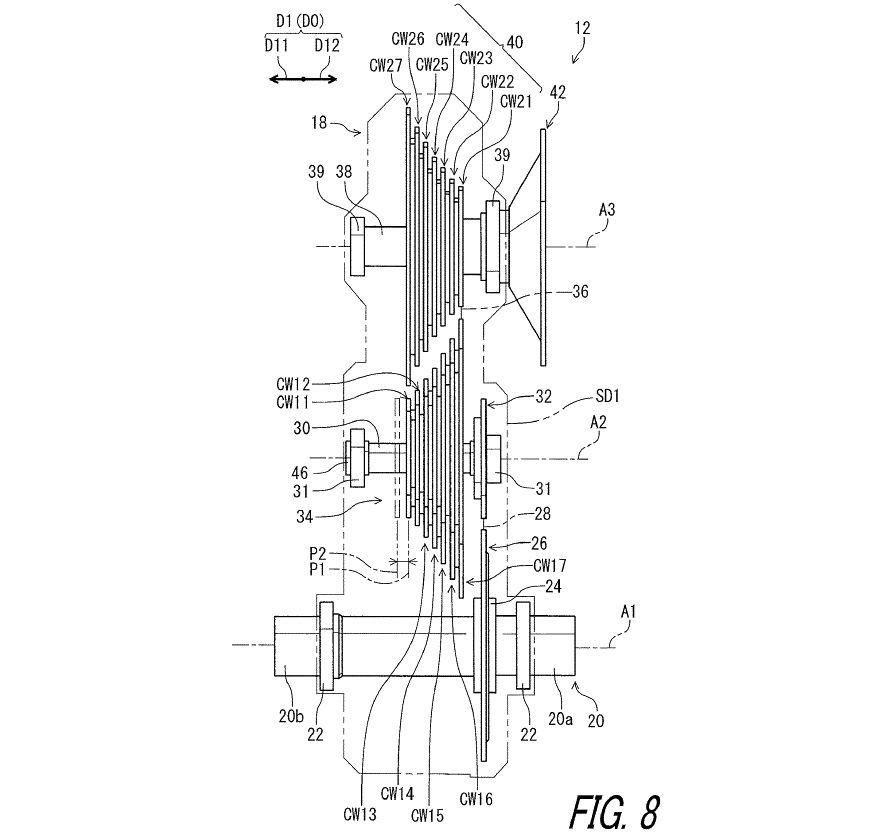

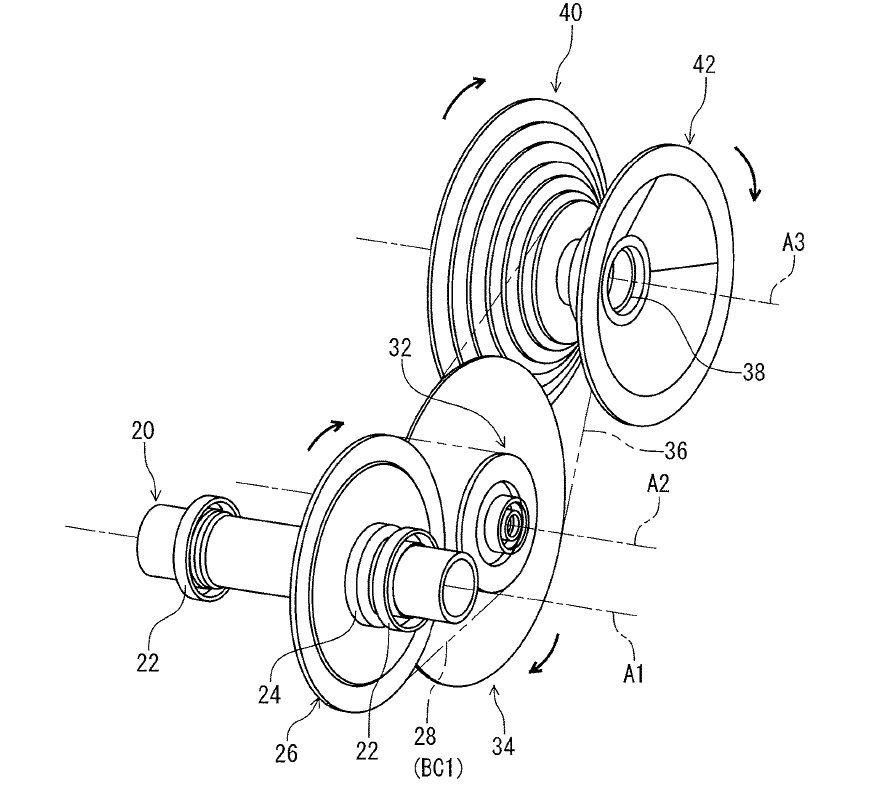

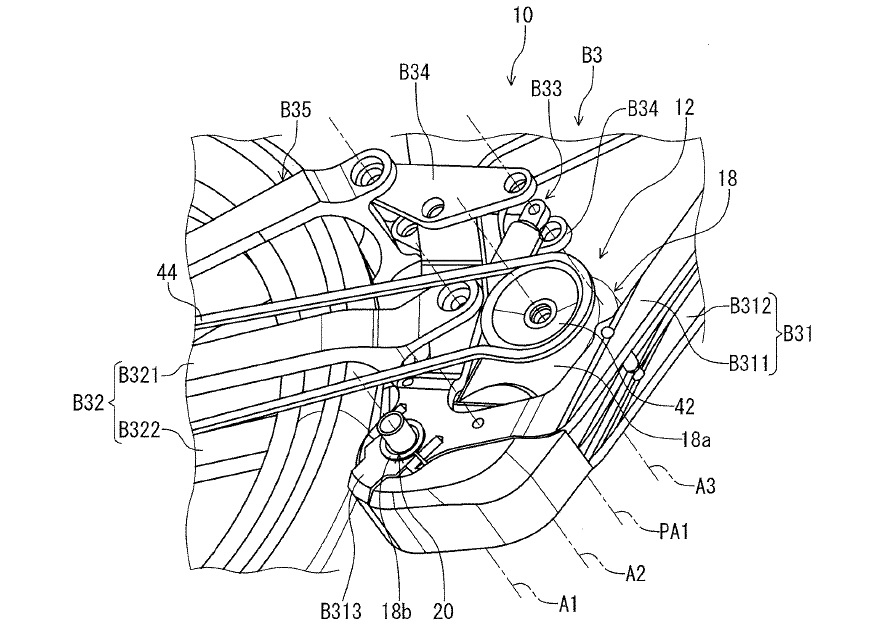

The biggest recent drivetrain update comes from Shimano, who filed a massive patent for an internal gearbox. It applies to road, mountain, or other styles of bikes, mounting to the bottom bracket area of the bike (similar to the Pinion system, for example).

However, the similarities to the Pinion system end there. Rather than using a heavy set of thick gears, the inside of the box has two cassettes and a secondary chain. At least one of these cassettes can move laterally during gear shifts, keeping a perfectly straight chainline for the internal chain.

The result is a total of thirteen gear choices, which should provide ample range in the ballpark of current 1 x 12 systems, or the Rohloff 14-speed internal gear hub.

The patent also includes extensive information on a proprietary lubricant that the gearbox requires for proper performance. One of the benefits of internal bottom bracket gearboxes or internal gear hubs is effectively zero maintenance – and we’d expect no different from the new Shimano system.

The big question mark is drivetrain efficiency. It’s well-known that current internal gear systems have a noticeable amount of drag compared to external drivetrains. While we can’t say for sure, the unique design of the Shimano system suggests that it may be more efficient – because it’s not unlike an external drivetrain in design – just moved indoors.

We’ll continue to follow all three of these stories for further developments.