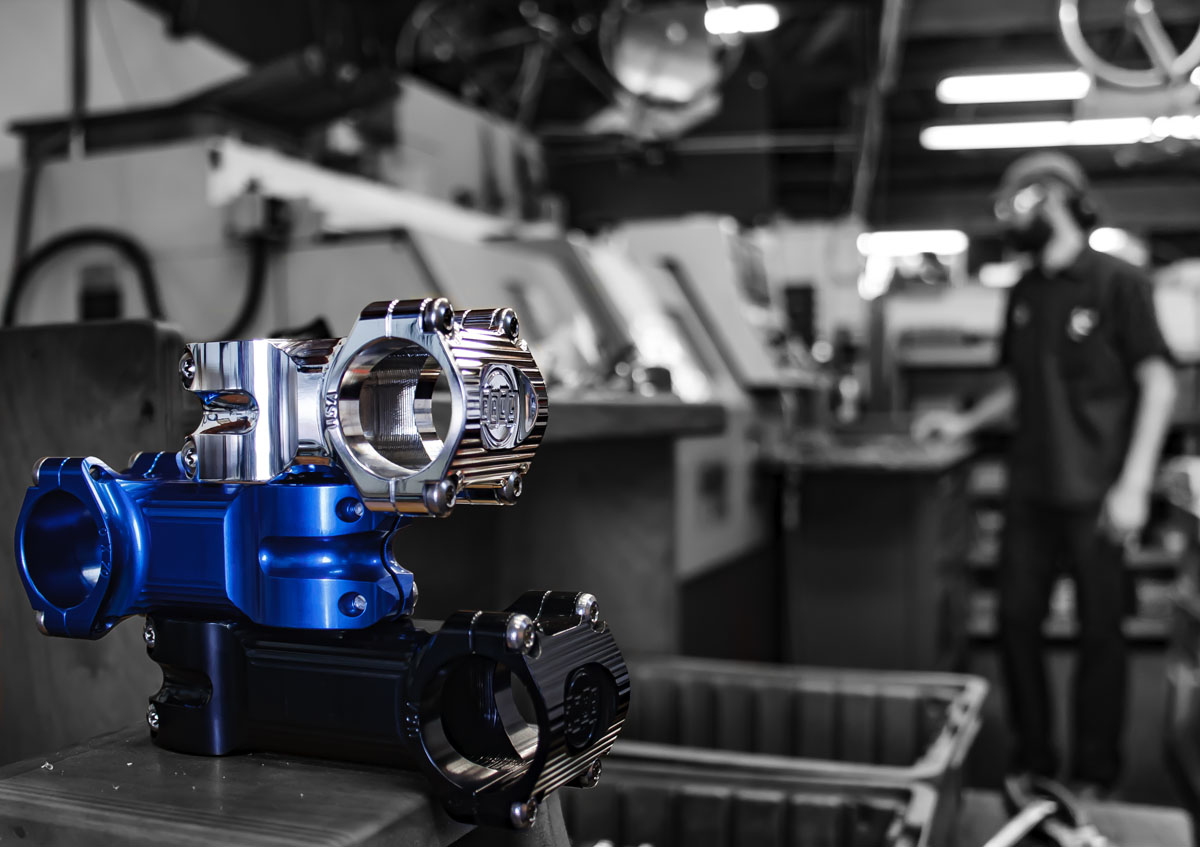

One day after Industry Nine unveiled their first stem to the world, Paul Component Engineering is reminding us that they too machine their own stems – and have for the past few years. But while the Boxcar stem has stood a shining example of how to turn a block of 2024 aluminum into a U.S. made stem for years, one thing that it did not offer was a 35mm clamp.

Over the years the company has received a number of requests from fans to create a 35mm version, and it’s finally here. While the merits of the larger handlebar diameter are still a hotly debated topic, having another option for a stem of the highest quality is never a bad thing.

When it comes to the Boxcar design, Paul Comp had this to say, “we started with American 2024 alloy due to its extremely high strength and fatigue resistance, allowing us to machine the stem walls extra thin from the outside and inside without sacrificing durability. 2024 is widely used in aerospace, especially wing and fuselage structures under tension. It’s more expensive and difficult for us to source than 6061 or 7075, but we refused to compromise on this project. We ran our prototypes through 1,000,000 cycles of above normal use stress without a single problem. Our rounded-box shape tested 25% stiffer than the competition, inspiring the name, and giving it a very unique, purpose driven aesthetic. We designed the faceplate to have massive handlebar gripping surface area from edge to edge, eliminating slippage and handlebar stress points, but again using 2024 alloy, which allowed us to keep it thin, light, and failure free.

We use over 20 different end mills, drills, saws and taps to make 1 stem, machining to .002” tolerance (that’s really tight for a stem). So yeah, it’s not a rush job, it’s more of an obsession project by bike nerds that just so happen to be engineers and machinists who take a lot of pride in their work.”

The newest version of the Boxcar isn’t much different in terms of design, but it does offer an all new clamp diameter for Paul Comp. The first 35mm stem will also be only initially available in 35mm lengths, hence its name of the 35 x 35. However, Paul Comp says a 50mm length version is also in the works. The 2024 aluminum stems are offered in high polish, or anodized black, silver, or purple. You can also still get the Boxcar stem with a 31.8mm clamp in 35, 50, 70, 90, and 110mm lengths with weights of 118-203g depending on the length. Pricing also varies by length, but the 35 x 35 will sell for $123 for anodized versions or $135 for High Polished. Available now.