Stan’s No Tubes showed up to Press Camp with two new sets of carbon wheels, but the material of the rim is only part of the story. The key to the new hoops was the ability to to build them off of their all new line of hubs. For years, Stan’s engineers have been making their own changes to existing hub designs, but as Director of Sales and Engineering Mike Bush put it – only a ground up hub design would be able to accomplish all of their design goals.

So that’s exactly what they did. In the making for over two and a half years, the Neo and Neo Ultimate line represents a complete reboot of Stan’s hubs. Only available in complete wheels (for now), the Neo hubs are the perfect anchor for the new Avion and Bravo carbon wheels…

Starting with billets of forged aluminum, the new hub shells are 100% CNC machined using a new process for increased precision. Stan’s tells us the move to a 5 axis CNC machine means that they no longer have to reposition the work to machine the two sides of the hubs which guarantees a perfectly concentric bore though the center of the hub. It also gives them increased control over intricate machining passes which enables more material to be removed than before.

The complete redesign of the hub includes things like new bearings that are 4mm larger in diameter and 2mm wider for increased durability. The new axle is first swaged then CNC machined and finally finished with a centerless round grinding process that ensures a perfect fit of the axle within the bearing.

The shoulderless design of the axle still allows for tool free disassembly, but the new Seal Lock technology means the end caps should stay in place. Rather than using a round o-ring like the previous hubs, the Seal Lock hubs use a U-Cup seal that not only makes the cap stay in place, but also results in less friction for a smoother spinning hub.

Another big change to the hubs is the new free hub body with the Neo running a 4 pawl system and the Neo Ultimate running 6. Engaging on a 36t tool hardened steel ratchet ring, the Neo free hub’s paws engage simultaneously for 10º engagement. The 6 pawl free hub engages in sets of three for 5º of engagement.

Both free hub bodies place the bearing out as far as possible and use a plastic clip to keep all of the pawls and springs in place. Machined to have better precision for the pawl pockets, free hubs will be offered in Shimano, SRAM XD, and Campy. Finally, a new comolded seal keeps the inside of the hub shell clean and the only part that would be possible to lose (the free hub spacer) has been anodized red for easy visibility.

Going back to the machining process and difference between the two hubs, you can see some of the additional material that has been removed on the Neo Ultimate hub (above, right) around the brake rotor mount. Available in Centerlock or 6 bolt, the Neo Ultimate hubs see extra machining time to remove extraneous weight as well as angle the non-driveside flange inward which is easier on the head/neck of the spoke. Ultimate hubs also receive an axle spacer that has been optimized again to remove every bit of weight possible.

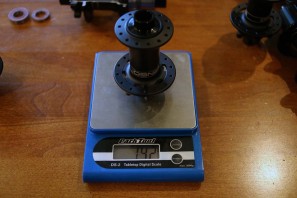

Even though the Ultimate hubs have more pawls, they still came in lighter on the scale with a combination 142/214g vs 157/263g for the Neo hub. Both hubsets have been torture tested by the machine known as Betty – a brute capable of exerting 220 ft lbs every 0.2 seconds straight into the free hub usually until failure. Previous Stan’s hubs would last around 50k cycles which was right in the middle of the 15k-90k industry average. Stan’s claims the Neo and Neo Ultimate hubs got to 250k cycles without failure and they decided to stop the testing.

Even though the Neo and Neo Ultimate hubs won’t be available aftermarket, they will be available in complete wheels with over 300 hub configurations to fit nearly every bike (including Boost) other than Lefty, RS1, and fat bikes. Most of the parts are swappable between the two hubs with each piece laser etched for easy identification.

Since the hubs are only available as part of a wheelset, two new carbon wheelsets seem like a perfect opportunity to launch the Neos. Mountain bikers will be most interested in the new Bravo carbon wheelset with a 32mm wide ext., 26.6mm wide int. rim. Calling their rim width the new Wide Right concept, Stan’s feels that the rim width should be optimized for the tire widths you’re going to run. Due to constrictions in tire design there is an effective range of rim width that beyond that you start to lose benefits. For the Bravo that sweet spot is apparently a 2.4″ tire with an effective range of 2.35-2.5″.

The rim itself is a squared profile that uses their React technology that was first introduced on the Valor carbon. Laterally the wheel needs to be as stiff as possible, but they don’t want a rim that is super stiff radially so the rim is designed to deflect vertically. Developed with the Atherton DH team, the Bravo rim had to be able to take a big hit which means it can deflect vertically 10mm compared to the Valor’s 7mm without damage.

Available in a Team and Pro build, the Team build will use the Neo hubs with Sapim Race 2.0/1.8 DB spokes and alloy secure lock nipples for $1575. The Pro build includes the Neo Ultimate hubs as well as custom Sapim Force triple butted spokes for $1900. Both wheelsets are 28h front and rear with 2/3x lacing for the rear and 2x on the front. One of the few companies to still support 26″ bikes, the Bravos will be sold in all three wheel sizes and include extra spokes and a tension graph from their build in New York of parts manufactured in Taiwan. Available in mid July, this will be the first chance you have to get your hands on the new hubset. The weights above of 863 and 740g (with valves and tape) are close to production for the Team build, but the wheels they had on display were built with the wrong spokes so the production weight will vary slightly. Of course the Bravo is tubeless compatible and uses Stan’s BST design and 25mm tubeless tape.

Along the same lines the Avion is to gravel and road as the Bravo is to MTB. Meant for anything from gravel to all road to even some cross applications, the Avion is a 28mm wide rim with a 22.3mm internal width. Again built with their React carbon technology and Wide Right tire sizing, the Avion’s sweet spot is a 28-32mm tire with an effective range of 25-40mm.

With the Avion Stan’s is introducing a new tubeless designation to try and eliminate some of the confusion that comes along with road tubeless. Calling it BST-R, the name means that the rim is compatible with high pressure tubeless tires – up to 115psi, but still works with low pressure tubeless as well. Aiming for neutral handling, the Avion uses a 41mm deep rim with 24f/28r spokes and 2x all around.

Sold in Team and Pro models, the Team will use the Neo hub and Sapim CX Sprint spokes and sell for $1729. The Pro model upgrades to Neo Ultimate hubs and Sapim CX Ray spokes for $2299 which came in on our scale at 814/676g with valves (55mm) and tape (25mm). Complete Avion wheelsets will be available this fall.

Stan’s also mentioned that the Valor wheels will transition to the Neo hubs in August, and the company will continue small part support for their previous 330 hubs.