Pole Bicycles out of Finland told us last year that they had started researching a carbon bike project, then abruptly brought that to a halt this summer over environmental concerns. But the real news out of that development was another all-new frame production method in the pipeline. Sticking with alloy, Pole have developed a process to entirely 3D CNC machine both front & rear ends of their next trail mountain bikes…

Cancelled Pole carbon fiber frame project

Back to the carbon for a second. Pole apparently spent around two years developing carbon frames before ultimately scrapping the project late this summer. Doing their research and development work in Finland they had the project close to finished, and headed off to China where they had lined up a suitable production factory to build the frames. But they just weren’t happy with the how the carbon production facilities there were treating either workers or the environment.

Now Pole made clear to us that they aren’t trying to save the world or claim some moral high ground. They just realized that they could do better themselves, closer to home. (Read more on their in-depth thoughts here.) A lot of that is about increasing production efficiency & decreasing production labor by moving more towards automation. And that certainly doesn’t rule out carbon further into the future. But it does make a lot of sense with this move to a EU machined alloy frame…

#AREYOUMACHINED CNC machined aluminum bike project

Now to that machined frame. Pole is keeping the final details close to their chest for now. But they have let out this rather revealing photo teaser, with a rendering of the complete bike in the background. Pole’s short link Evolink suspension design appears unchanged and still keeps two bottle cage mounts inside the front triangle. This frame also appears to route all cables internally (that cable port in the downtube is likely to route the rear derailleur, not a sideswing front derailleur) and has a low direct-mount for a chain guide in place of ISCG tabs.

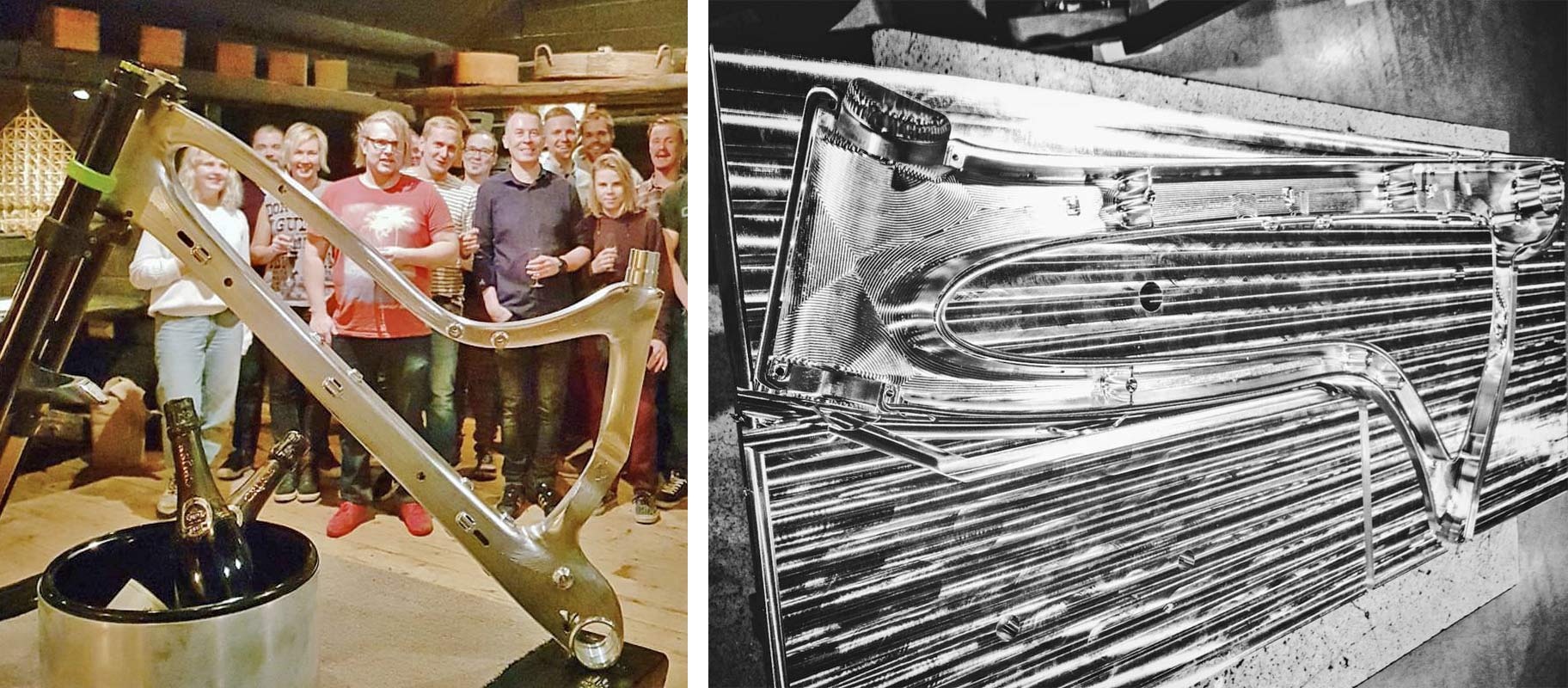

Pole says the new Super-Enduro bike is being 100% CNC machined in Finland out of aerospace grade aluminum. They claim it will in no way be hand made, leaving production almost entirely up to robots. That doesn’t really answer how you end up with a hollow aluminum shape. Is the bike a welded-together clamshell design?

What we do know is that more details are coming soon. And the first bike will be available for pre-order in just over one month’s time – on Black Friday (Nov 24).

The new bike of course will carry their unique new school geometry – super long wheelbases and slack headtubes – for unmatched descending. First up will be what they are calling a Super Enduro frame (we are guessing that puts it in the 150-160mm travel range), then almost immediately followed by a DH bike. That supports Pole’s claims that this new manufacturing process yields an incredibly tough and strong frame.

After that a light trail bike like their Evolink 130 is expected to follow in a new CNC variant, and then even a trail e-MTB. OK, that’s pretty much what we know on the Pole #areyoumachined bikes for now. Rest assured, we will update you when we find more details.