A new Czech startup named Posedla is working on taking customized bike fit to the next level with their new custom 3D-printed carbon saddle concept. While there are now a few large and small companies offering premium, lightweight carbon saddles topped with 3D-printed TPU padding that promises a better balance of comfort and support… none currently are taking advantage of the individual customization potential offered by 3D printing. That’s where Posedla comes in…

Posedla custom 3D-printed padded carbon saddle

Specialized’s Mirror and Fizik’s Adaptive technology lines have both bonded 3D printing TPU padding onto their top-tier road bike saddles since 2019. Adding recently to the mix, Bjorn’s 135g Setka saddle uses the same Digital Light Synthesis (DLS) UV-tech from the exact same Carbon Inc. 3D printer in California, again employing 3D printing to create varied structured support zones across the saddles. But the level of the support, the latticework structure itself, and the shape of the padding & saddle have all remained the same. There are some different width options and Specialized has both Power & Romin shapes, but nothing custom so far.

Posedla’s concept is then to take advantage of the flexibility of 3D printing to bring more customization to the end-user cyclist, in order to improve rider comfort and performance.

The custom saddle startup project of Martin Řípa and Jiří Dužár is being fueled by significant support from leading consumer 3D printer manufacturer Prusa Research and their PrusaLab makerspace hardware accelerator program to develop the concept, as well as from the state for their continued job creation.

Posedla developed their fit concept and dialed in their ideal saddle pressure support mapping over the last year together with custom bike fit studio KOA – the same fitter who we worked with to review GebioMized’s pressure mapping for their Secret Saddle Club fitting back in early 2020.

Tech details – How does it work?

The Posedla project is designed to incorporate individual rider data from personal bike fitting, a questionnaire on riding style, and a home-kit that custom measures the rider’s sit bone width and individual pressure distribution. Taking all that data into consideration, a Grasshopper-powered generative design program they have developed within Rhino 3D modeling software creates a personalized ideal saddle shape along six adaptable custom curves.

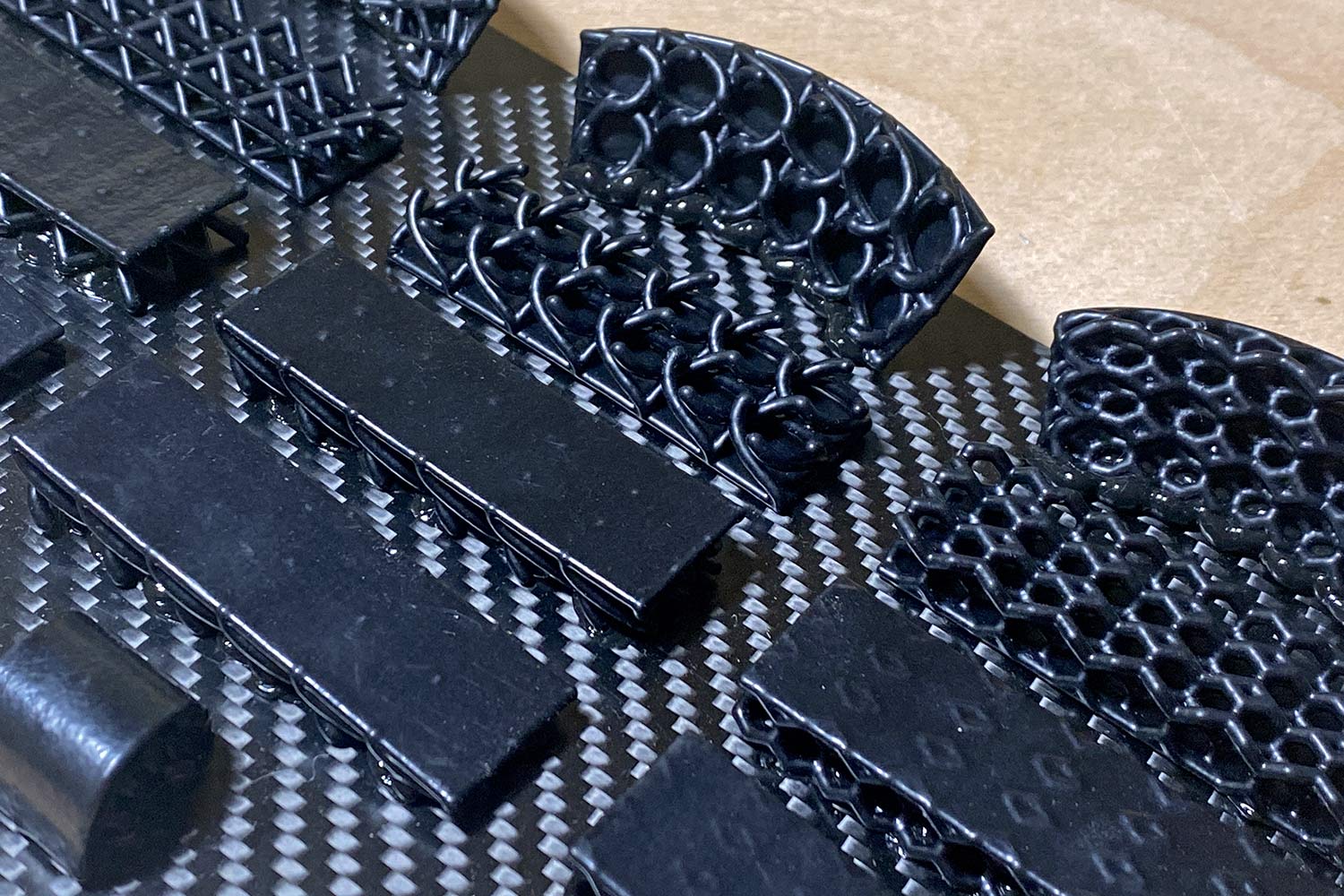

That fully-custom shape then is created in a 3D-printed TPU padding structure using an additive Selective Laser Sintering (SLS) process, unlike the DLS tech used by the other three saddle makers. The final TPU latticework padding structure design is still in development, as Posedla refined the balance of support & comfort within their generative custom framework.

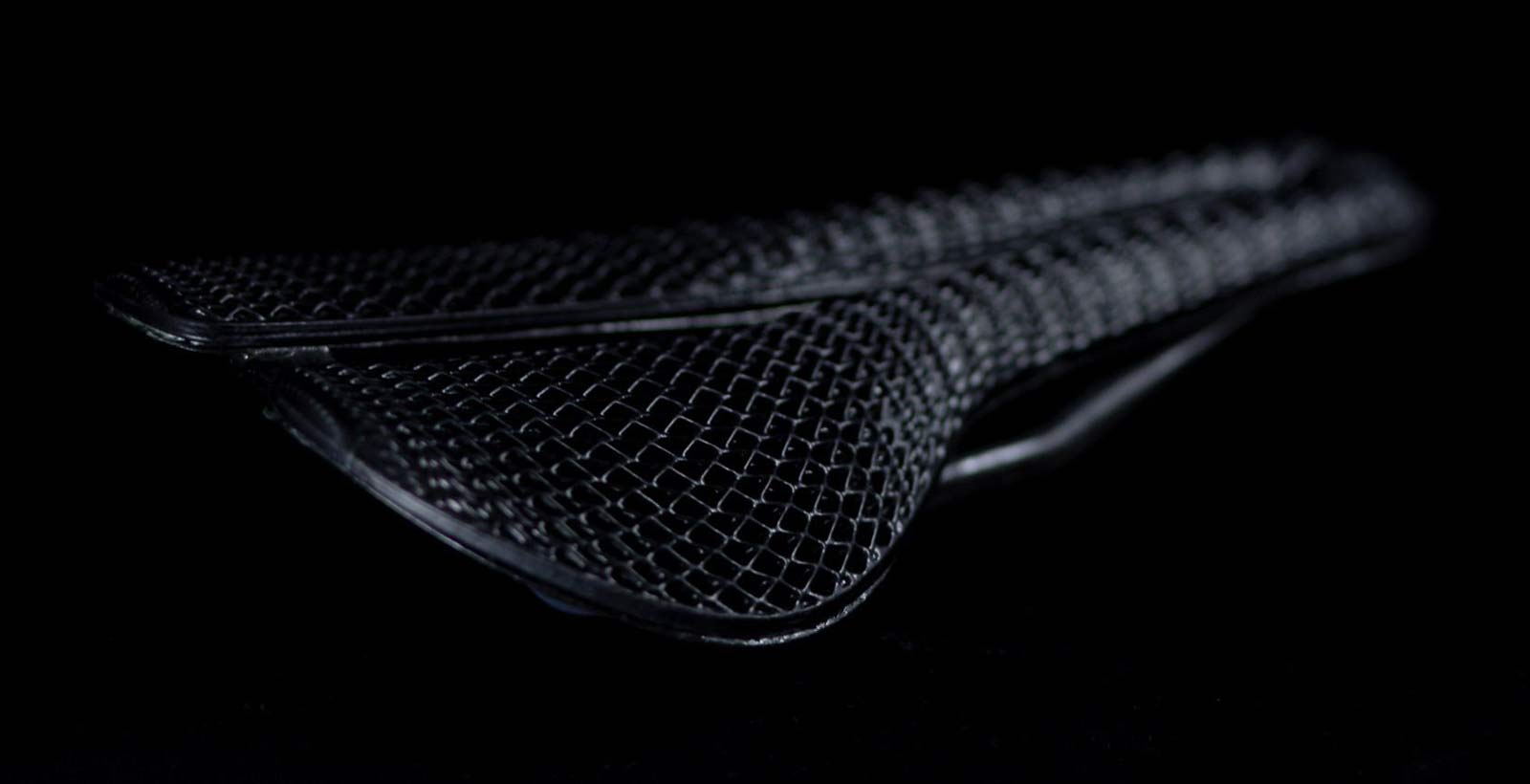

The custom padding is then bonded on top of one of six stock carbon shells – varying in width and curvature. Those standard two-piece carbon shells with 7x9mm oval carbon rails weigh around 95g, plus the weight of the still-in-development 3D-printed padding.

All of the manufacturing steps are completed locally in the Czech Republic by Posedla and a specialist Czech 3D-printing contractor.

Posedla custom saddle – Pricing & availability?

Posedla are still finalizing their process, refining their padding structure design (seen here as the 3rd generation of functional prototypes), and currently building out their new local manufacturing facility near the CZ/PL border. So, final consumer pricing hasn’t been officially set. But we’ve been told the complete process and custom saddle should cost from ~275-350€, putting it on par with the stock size offerings from other 3d-printed padded saddles.

As for timing, you should only have to wait until spring 2022. We’re quite curious, and hope to test out the custom fit saddle process soon, once it is broadly available.