“What’s the most interesting thing you’ve seen?” That’s always a popular question at trade shows. This year at Sea Otter, I found myself coming back to the HiT or Hinged Transmission from Praxis as the answer.

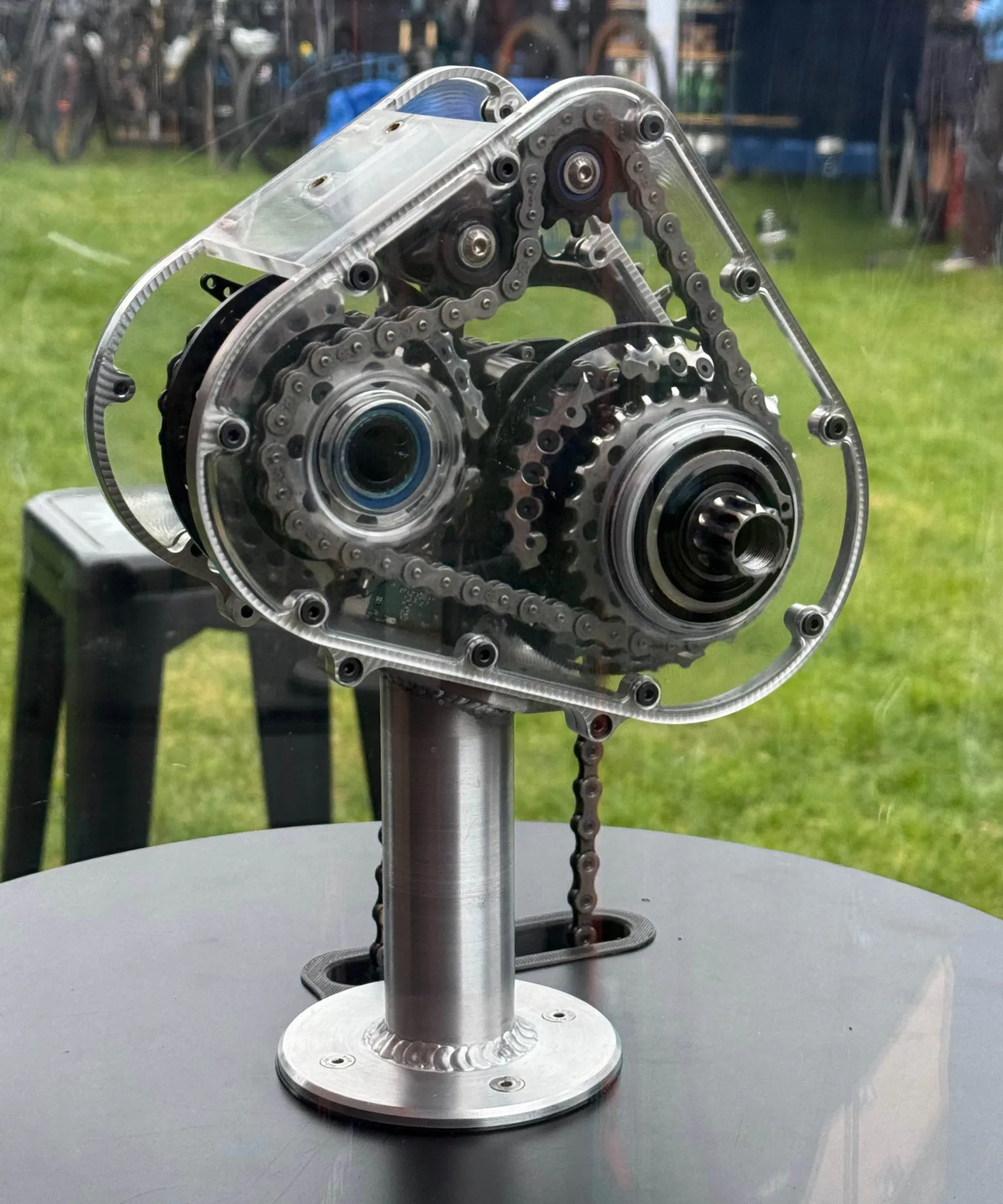

Praxis has been working on their gearbox for quite a while at this point, and it’s still thoroughly in the prototype phase. As they tell it, they were ready to show it to the world in hopes that they may find a partner in the industry that wants to integrate it into their bikes and help bring it to production.

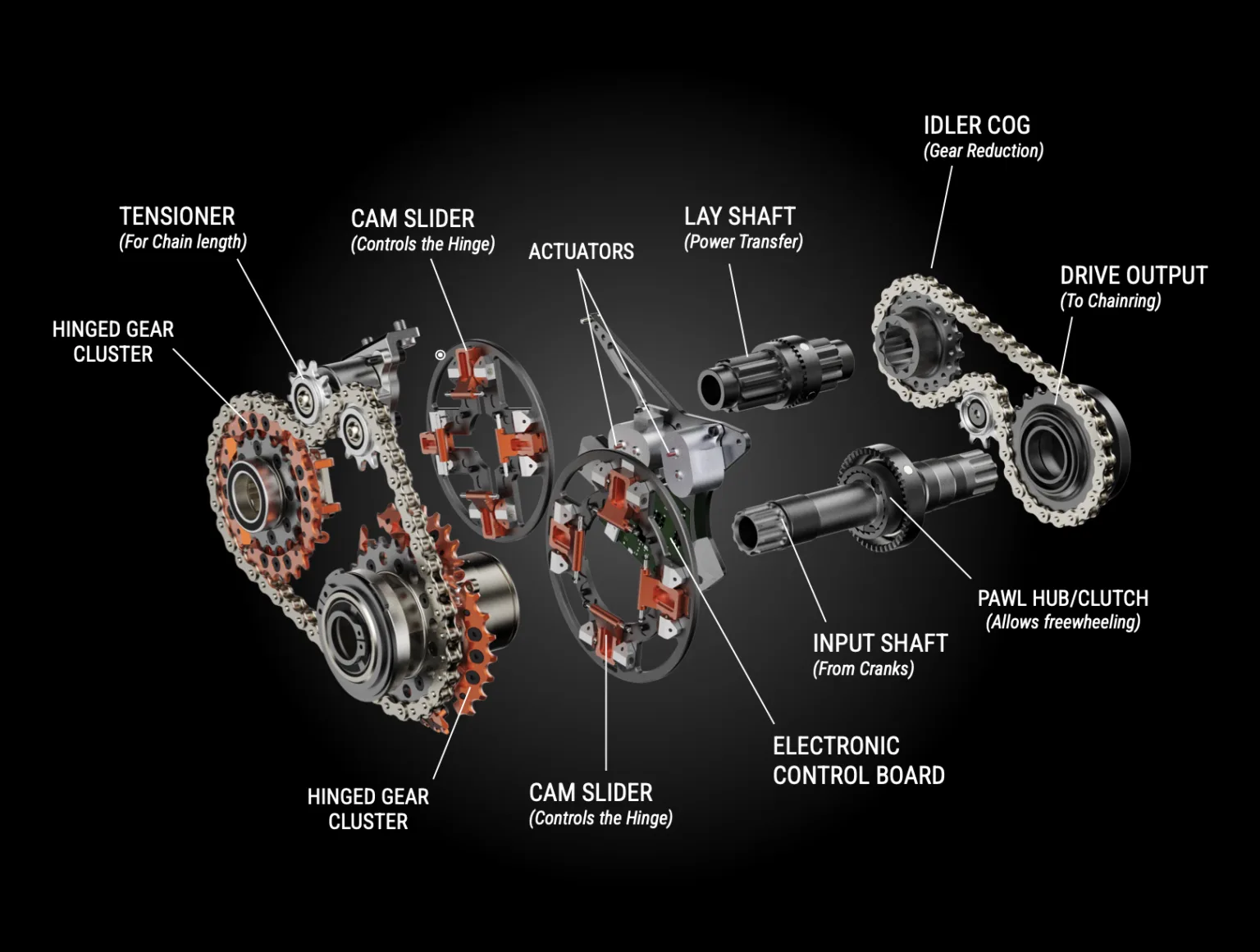

They do have a number of working prototypes at this point, including a number of custom bikes that have been built around it from super commuters like the Calfee above, to full-suspension mountain bikes. One of the big advantages to the design is that the input and output for the gearbox can be located in different locations. That allows for outputs that are concentric with the input, or not, placing it higher in the case of a high pivot MTB for example.

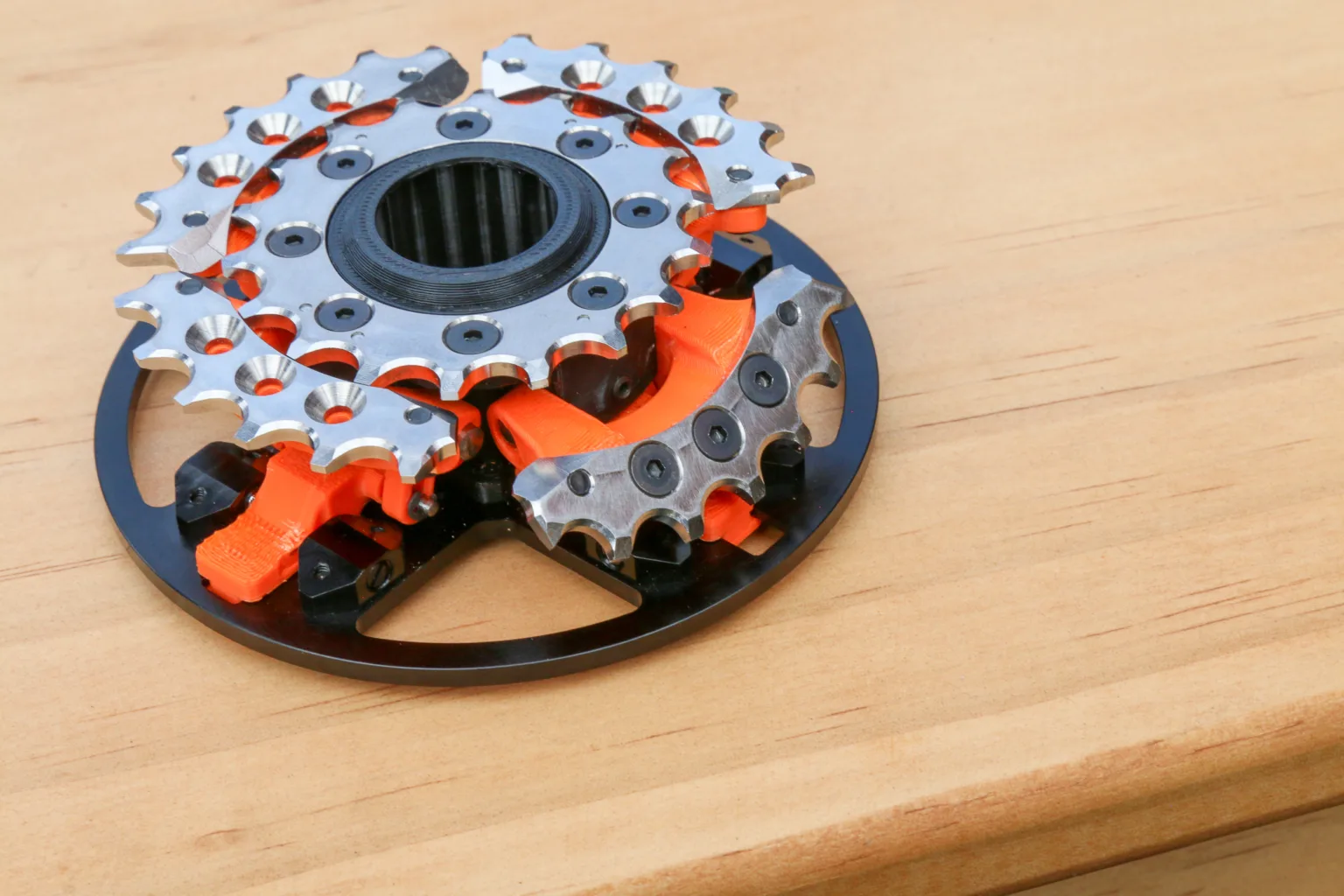

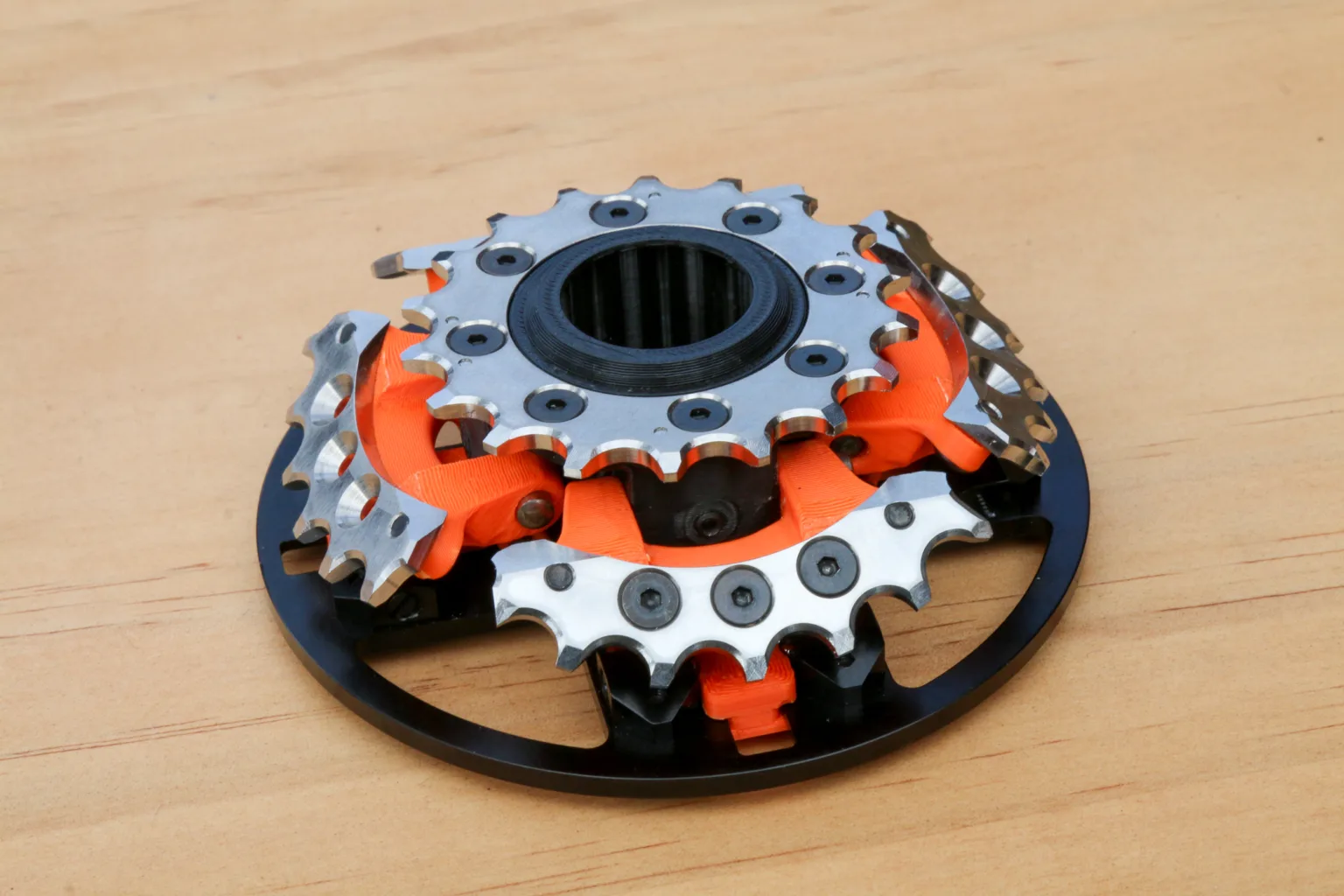

The gearbox gets its name from the hinged, folding gear clusters that are essentially two gears in one. There is a smaller inner gear, and a larger outer gear that is hinged, and that outer gear ‘folds’ over as it rotates, which allows the chain to either drop from the large to small, or climb from small to large – all under extreme load. Praxis’ design engineer mentioned that it works so well under power, that you almost have to retrain your brain to keep pedaling while you shift.

That shifting can also be sequential or non-sequential with programmable electric shifting that can be programmed, or set up as fully automatic. Gearing is a function of the number of gear clusters, with total speeds ranging from 4 to 16.

Praxis also mentioned that compared to the prototype, they think the number of parts in production could be cut to half. That could result in a transmission with fewer parts than a regular drivetrain, and it’s built for serviceability with the ability to replace individual parts.

In terms of size, the current limiting factor is the chain. Praxis states that if they went to a custom chain, it could be made smaller by about 25%, potentially reducing the size of the whole unit.

Already granted multiple patents with more on the way, Praxis plans to integrate the transmission with an ebike motor as the next step. Currently, it’s just Praxis working on the project, but after seeing it in person, it seems more than likely they’ll find someone to partner with in the near future. For more details, check out the Praxis Works mini-site.