Is smoother faster? On the surface, that seems like an obvious question. We all may feel that smoother is indeed faster, but just how do you quantify that? That question turned out to be the starting point for the all new, Specialized Roubaix. With so much emphasis being placed on making smoother bikes and trying to improve rider comfort, Specialized realized they first needed to understand just what made a bike smooth and whether that made it fast.

That quest led them back to McLaren. As we know, this isn’t the first time the two companies have worked together, but this time it would be under completely different circumstances. The McLaren Venge was all about how they could go about making the fastest aero road bike. For the new Roubaix, McLaren would need to use their blend of science and magic to quantify what human test riders couldn’t which led to the development of the Rolling Efficiency Simulator. This included everything from complex mathematical models to a chassis dynamics rig that vibrated the rider and the bike to see how riders perceive vibrations, as well as a rolling system that was able to model how impacts affect the entire bicycle essentially one pixel at a time. The beauty to the McLaren method is that all of this testing produced an incredible amount of data in a very short period of time and allowed them to really study each component’s effect on the whole system without actually manufacturing anything.

In the end, they were able to verify something they knew subjectively, that smoother IS faster…

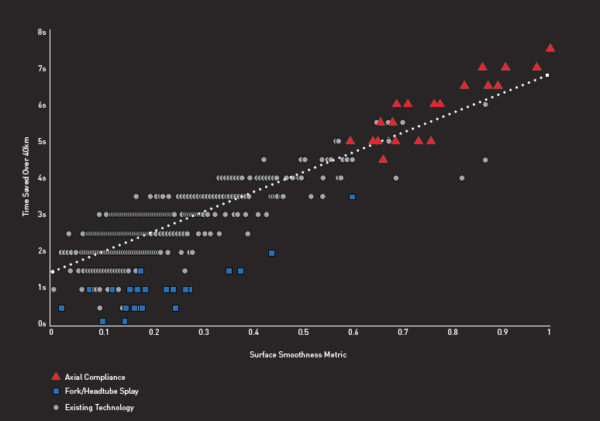

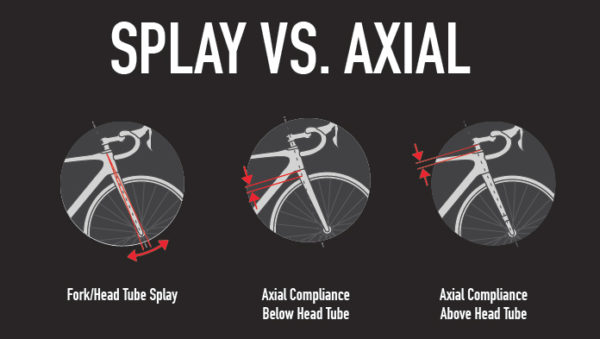

While McLaren was able to prove that smoother is indeed faster, more importantly they dug into the different ways of making a bike smoother and how those affect the speed. Splay vs. axial compliance turns out to be a major factor in the bike’s design with splay commonly used as a way to add compliance. While it’s sort of effective at smoothing the ride, it’s not the most efficient way to go about it. Axial compliance below the head tube (head shock, suspension fork, etc) is more efficient at adding smoothness and is significantly faster though it still has efficiency losses through suspension bob and can affect the bike’s handling. That leaves axial compliance above the head tube which appears to offer all of the smoothness benefits and performance without the same disadvantages. McLaren’s testing also found that bikes were much faster when the compliance bias was towards the front of the bike rather than the rear.

You may remember a post back in January of last year with Specialized’ patent of a cobble eating suspension fork, which at one point was exactly where they were headed with the Roubaix’s design. Prototype forks were created with various methods of reducing twisting and prototype frames were made as well with the seat stays cut above leaf springs that were attached to the seat tube. All of this worked great from a comfort perspective, but it also introduced compromises in handling, bobbed under power, and made the back end of the bike feel disconnected.

At the end of the day, the Roubaix has a tough task. It has to be a Paris-Roubaix winning race bike while maintaining compliance for everyday riders. This suspension concept was clearly not the answer, and the whole thing after quite a bit of prototyping investment was scrapped.

That concept of a compliant upper half and a race bike underneath, led to the creation of what Specialized is calling the Future Shock cartridge – essentially a suspension steerer tube, but only on the upper half. Specialized found that the fork was one of the most critical components to handling with front stiffness being one of the most important metrics. So the answer was to create a fork that was just as stiff and precise from the headtube down, while the Future Shock cartridge suspends the rider’s hands above. In testing the Future Shock wasn’t just found to be slightly more compliant than the Roubaix SL4, it was up to 4538% more compliant. Those numbers don’t even seem real, especially compared to the back of the bike which gained just 19%.

Now before we go any further, there’s no getting away from the inevitable suspension stem comments. While the Future Shock does have some similarities to the suspension stems of old in that the handlebar moves up and down, it’s still quite a bit different. Inside the cartridge are three different springs – the main spring, booster spring, and top out spring. As demonstrated by Chris D’Aluisio, the handlebar essentially floats in the middle of the travel with the main spring and booster spring providing the bump absorption and the top out spring keeping the system from topping out when you pull up to sprint. Consumers will also have three levels of main springs that can be run with soft, medium, and firm settings. In total there is 20mm of travel – 17mm down, and 3mm up. That 3mm keeps the handlebar almost locked out when you pull up so sprinting is still efficient as possible. The cartridge is kept as simple with a three-sided needle roller bearing without any seals or wipers, just a boot that sits between the headtube and the stem.

In order to offer a range of fit, the headtube is shorter than the previous Roubaix with the Future Shock cartridge making up the difference. Any stem can be run with the included shim for the cartridge, and in total there is 30mm of stack height adjustment through three different positions of the cartridge itself. According to Specialized, the stem stays in the same place on the cartridge while its height can be adjusted to three different positions. Between stem angle changes, and riser or flat road bars, they say that the bike can accommodate a huge range of positions. Also, since there is no longer a starnut or compression plug, headset adjustments are made with the two grub screws on either side of the aero top cap.

You might guess that the big chunk of metal in the steerer tube adds a good bit of weight, and you’d be right. About 295g to be exact. Fortunately, the new Roubaix frame without the cartridge is the lightest frame Specialized has ever made. That seems absolutely crazy, but Specialized maintains that the S-Works disc brake frame comes in at just 900g, making it their lightest yet. Add the weight of the cartridge and it’s the same weight as the previous Roubaix meeting their goal of adding features without adding weight.

Just because Specialized and McLaren found that the front of the bike had the greatest impact on smoothness, comfort, and handling, doesn’t mean they neglected the rear. In a similar thought process, Specialized didn’t want to ruin the precise handling of the bike by decoupling the rear end but they did want to eke out as much compliance as possible. To do so, they relocated the seat post clamp 65mm lower to the junction with the seat stays. The seatpost exposed above it is free to flex with a rubber collar up top to keep things sealed. Combined with their CG-R seat post, you get a more compliant ride than the past Roubaix, though nothing like the front of the bike.

Why not just match the height of the top tube to that of the seat clamp? Aesthetics for one, and Specialized claims the higher top tube equals a stiffer frame.

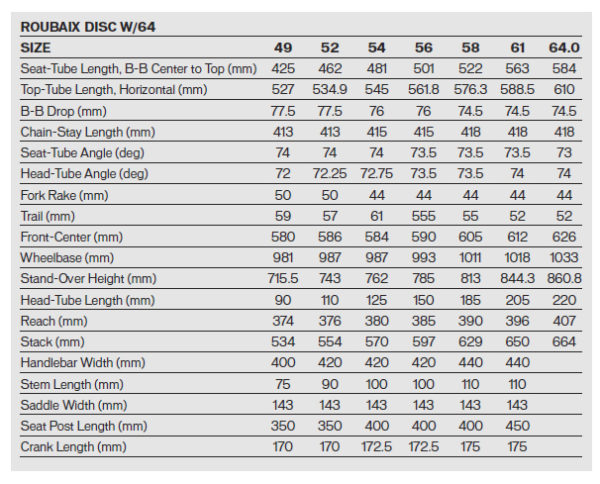

The frame also sees new geometry that is optimized for 28mm tires on the new Roval CLX 32 wheels (more on those in another post). At this point, anyone on a Roubaix should probably be riding bigger rubber, and Specialized has built the bike to reflect that. It also features the same fork offset and head tube angle as the Tarmac which gives it faster handling. Without the Future Shock suspension, Specialized says they wouldn’t have been able to make this geometry change, but separating compliance means new opportunities in frame design.

Tire clearance on the frame is claimed to be 32mm, which seems accurate given that the 28mm tires on the CLX 32 rims were said to measure out to an actual 30mm.

Of course aerodynamics can’t be ignored either. Compared to the Roubaix SL4, the new Roubaix is 16 seconds faster over a 40k time trial in aerodynamics alone with much of that speed coming from a redesigned fork. Along with flat mount disc brakes front and rear, the Roubaix frame uses 12×100 and 12x142mm thru axles front and rear to hold everything together. Specialized stated that they still believe in SCS, but they see the value in moving to one standard for riders and shops and will be using 12×142 and 12x100mm axles moving forward.

Since road bikes don’t take kindly to cutting a huge hole in the frame for storage, the Roubaix includes a new bolt on SWAT Box that mounts just above the bottom bracket with two bolts. One size box will fit all frames and the 180g box weighs 400g when fully loaded with the included tube, CO2 inflator, tire levers, and multi tool. And yes, that is a threaded bottom bracket.

At the top of the line, Specialized will offer an S-Works level Roubaix complete with SRAM Red eTap that will tip the scales at 15.85 lbs. As you might expect, this build will also make a big hit to your wallet at $10,000. Other builds will include the $6,500 Roubaix Pro UDi2, $4,600 Roubaix Expert UDi2, $4,000 Roubaix Expert, $3,200 Roubaix Comp, and the $2,600 Roubaix Elite. Roubaix framesets will also be available in two colors and will include the frame, fork, thru axles, bottom bracket, seatpost, and Future Shock suspension. Zertz may be dead for the newest version of the Roubaix, but Specialized will still have three models of the previous Roubaix SL4 available presumably as lesser priced options next to the new models.

Over on the Ruby side for the women, the bike sees all of the same targets with the same Rider-First-Engineered frame design with the Future Shock suspension. While the frame features the same tech, the geometry is different with a taller stack and longer wheelbase to prevent toe overlap. Frame sizes start at just 44cm and go up to 58cm, all with 700c wheels and 26mm tires. Rubys will be available in the same builds at the same prices as their Roubaix counterparts with prices from $2,600 to $10,000. Like the Roubaix, three versions of the SL4 Ruby will be sold as well.

First impressions from the Hell of the North are up next!