ReTyre’s unique ‘carbon-neutral’ tire tech looks set to make big inroads in performance and real-world availability, thanks to a new development partnership with Vittoria and a fresh round of venture capital investment. Together, the funding and Vittoria collaboration will help ReTyre expand production of their pioneering sustainable tires. And it signals a shift from making tires for less-demanding applications like kids’ bikes and strollers, stepping up to make durable, high-performance eco tires for everyday urban and commuting bikes and ebikes.

reTyre injection molds bike tires to go carbon neutral

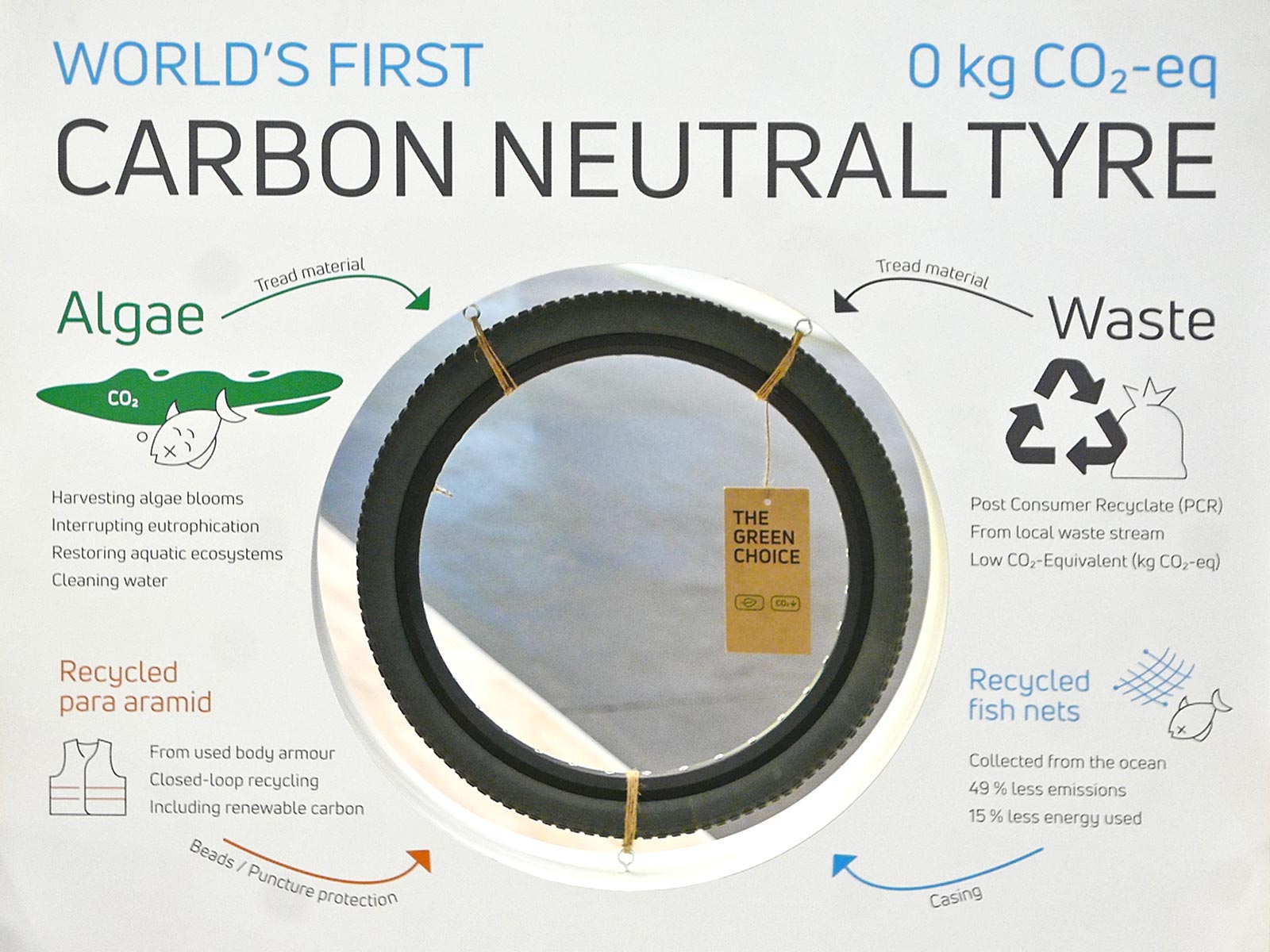

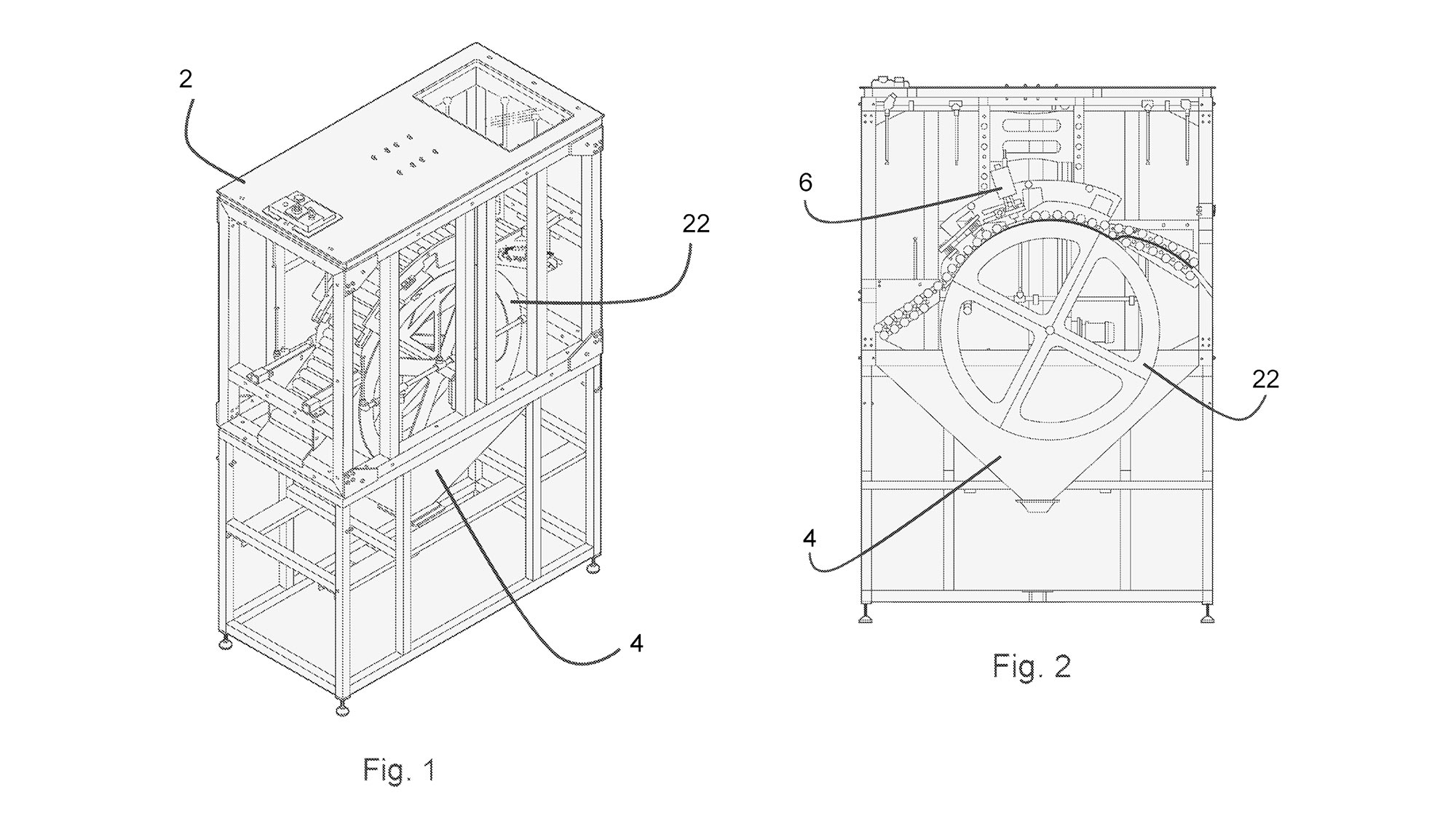

We covered ReTyre’s uniquely sustainable tire manufacturing tech two summers ago when they debuted the “world’s first carbon-neutral tire”. Their patented and tightly-protected process essentially boils down to continuous manufacturing, where they injection mold a mix of recycled, reclaimed & bio materials over a strip of fabric fed through a machine to create a really long roll of tire casing. The same with the recycled & reclaimed thermoplastic elastomer that makes up the tread, continuously injection molded onto the casing. Only then, their automated machines close & bond the loop, creating the final tire in the diameter needed.

The next piece of the eco puzzle is that ReTyre can produce the basic building blocks of their tires in bulk in one (or multiple) central locations. Then, they can use smaller and more flexible local manufacturing facilities to complete the construction of the tires, nearer where they are needed with much less waste.

Ultimately, ReTyre hits their zero-carbon footprint by upcycling waste and employing carbon-negative algae captured in the restoration of damaged aquatic ecosystems. And they do it all, while still creating tires that rival conventional vulcanized tires for performance and durability. Only, the ReTyre tires are also 100% recyclable.

Hatch Blue and Fundracer fund reTyre with €7 million venture capital investment

Seven million euros of new venture capital backing is the heart of ReTyre’s announcement today.

The fundraising was led by Hatch Blue’s Blue Revolution Fund, a “global venture capital fund… backing ventures accelerating the sustainable growth of the aquaculture industry“, tied of course, to ReTyre’s use of algae in the tread of their eco tires. Adding to that is Fundracer, another VC fund, “investing in innovative start-ups and scale-ups driving the future of mobility through safety tech, zero-emission solutions, and sport tech“, plus participation from previous ReTyre backers.

ReTyre explains that this round of new financial backing will pay for the completion of “its first fully automated production cell in Norway, followed by a second facility in Asia in 2026“. That will allow the tire maker to “scale up production, deliver on its large order book, and reach profitability“. But it also lays the groundwork for the company’s next steps.

ReTyre + Vittoria = carbon-neutral performance bicycle tires

And that next big step from our perspective is the ‘Strategic Collaboration Agreement’ with leading performance tiremaker Vittoria.

Up to now, ReTyre has been supplying their continuous injection-molded ‘eco’ tires to typically less-demanding applications – like stroller, bike trailers, and kid’s bikes. That wasn’t really due to any inherent performance limitation of their sustainable injection-molded technology. It seems more based on less buy-in from more performance-oriented segments. Now, targeting the ‘performance utility’ market with the Vittoria ‘co-development partnership’, ReTyre aims to broaden their customer base. And at the same time, bring more sustainable bicycle tires to many more cyclists.

“After a decade of focused R&D, we’re proud to disrupt the industry with a technology that delivers a new level of performance while enabling true circularity and a sustainable solution in tyre manufacturing. Support from Hatch Blue, Fundracer, and our co-development partnership with Vittoria, reflects deep confidence in both our vision and the breakthrough potential of our platform as we continue to scale.”

– Paul Magne Amundsen, reTyre founder & CEO

“We’ve followed reTyre for many years and are convinced that their unique production method can successfully be applied to utility bicycle tyres. Vittoria stands for performance and sustainability, and reTyre’s technology delivers both. We’re excited to collaborate and bring this next generation of sustainable performance tyres to market.”

– Stijn Vriends, Vittoria Chairman & CEO

We asked ReTyre what’s next, and what exactly they mean by ‘performance utility’?

What’s next for ReTyre?

For them, the new funding is all about taking their proven injection-molded manufacturing tech, and scaling it up to an industrial level that will mean getting more sustainable tires to more cyclists.

They describe that performance utility means developing tires “designed for high-use, real-world applications where performance, durability, and reliability genuinely matter“. That means bringing recyclable, carbon-neutral tires to everyday urban and commuter bikes. But also sustainable tires made to withstand the extra abuse of ebikes, cargo bikes, and heavier city bike platforms like share bikes and fleet bikes used for things like deliveries and daily transportation.

ReTyre explains even greater environmental benefits for these high-use applications where their tires can deliver “predictable handling, long service life, and low maintenance, while also meeting increasingly high expectations around sustainability and supply-chain efficiency“. Plus, with the 100% recyclability of their core thermoplastic elastomer construction, when these ‘performance utility’ do wear out, they won’t just become another waste stream. In fact, one of ReTyre’s most recently published patents is for an automated machine that uses water jets to separate the tire tread from its casing for quicker recycling.

Their goal in working together with Vittoria “is not to chase niche race products, but to bring performance thinking into utility tyres, applying high-level design and validation standards to categories that are ridden daily, often intensively, and where total cost of ownership really matters“. That should mean the same affordable mid-tier pricing you would expect from comparable commuter bike tires. But soon, with much improved environmental sustainability.

We’ll be keeping an eye on ReTyre. And we look forward to the opportunity to test out a carbon-neutral performance tire as soon as they are ready!