Hope Tech is still probably better known for their MTB products these days, but a number of new projects are helping to change that. From their hydraulic disc brakes for dropbars to carbon fiber spaceships for track racing glory, Hope is making it clear that they’re a bicycle company built on creating products with extreme precision and performance.

Recently at Eurobike, we got our first look at the new Hope RX crankset. A stunning new crank designed specifically for road and gravel use. While carbon might be found on many current light weight cranksets, Hope shows that it’s not always needed to come up with something impressively light…

Unboxing

Opening the box, you’re greeted with a jewelry like presentation and a gleaming crank arm with the light bouncing off the intricate CNC tool paths. Everything is expertly packed with the same precision you’ll find in the product itself.

Hope’s First Two-Piece, Hollow Crank Arm

You’d be forgiven for thinking the crank was one solid piece of aluminum. The machining is so precise, that the seam between the two halves of the crank arm is starting you right in the face without your even knowing. But it is constructed of two pieces – once unnecessary material (read weight) has been removed from the inside of the arm, the two pieces are joined with a “structural adhesive injected under controlled parameters to ensure the perfect bond every time.” Then the final machining is performed after the two pieces have cured resulting in that perfect appearance. This apparently the first time that Hope has ever offered a two piece, hollow crank design.

Installation

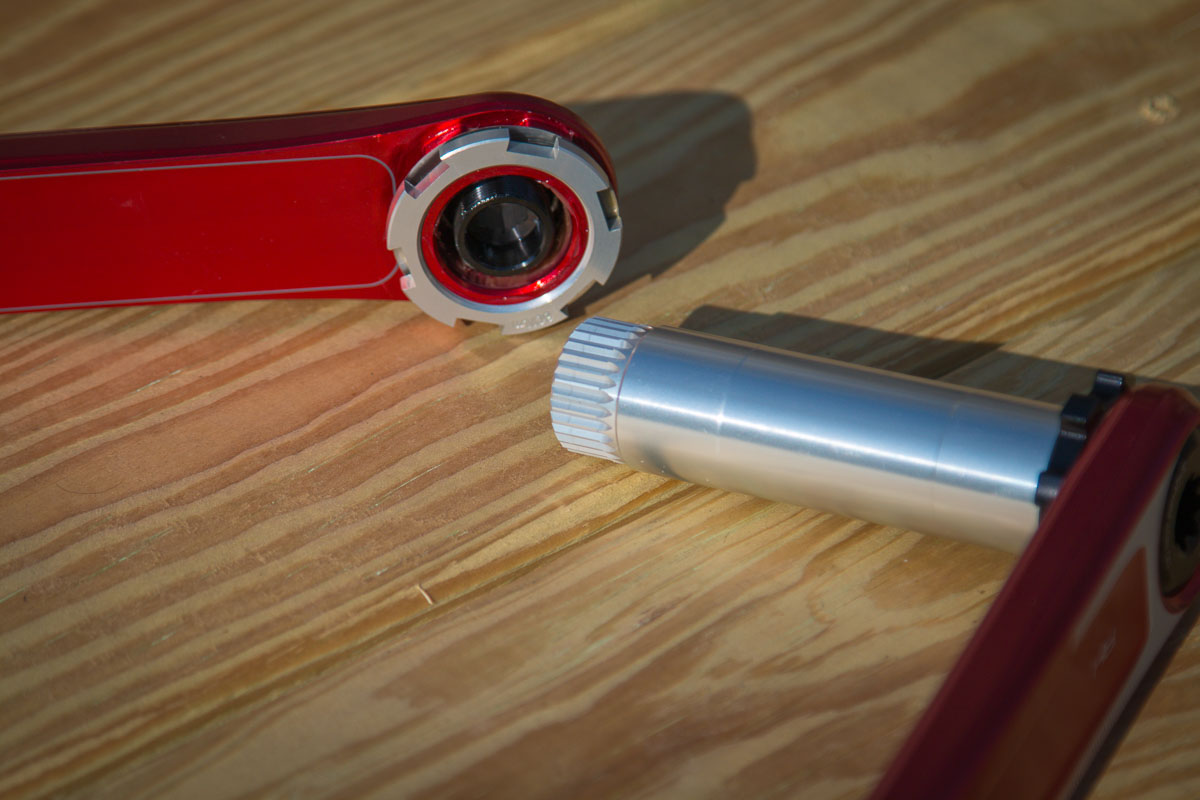

The RX crank arrives in two halves with the spindle attached to the non-drive side crank arm. The ‘Do Not Remove’ warning on the non-drive side seems to indicate that the 30mm spindle is permanently attached and can’t be swapped out.

Installation and removal of the crank arms is pretty straight forward. A single self extracting 10mm bolt is found on the driveside of the crank. Line up the splines and tighten down to 50Nm to install. Simply unscrew the same bolt to remove.

Direct Mount

It seems that direct mount chainrings are becoming the norm and the RX crank is no different. You’ll find a proprietary five notch asymmetric fitting which is designed to work with the Hope direct mount narrow/wide chainrings which are offered in 38, 40, 42, and 44t sizes. You’ll need the Hope HC105 tool to install the chainring locknut, which are both included with the crankset. The narrow/wide Hope chainrings are compatible with 10, 11, and 12 speed drivetrains.

Additionally, Hope offers a direct mount spider with a 110 BCD so you can run your rings of choice in 1x or 2x configurations. Technically, the crank is optimized for 1x use with a 45mm chainline, but Hope says a 2x will work just fine.

Bottom Bracket

Built with a 30mm spindle, the RX cranks are able to fit just about any frame with one of Hope’s many different bottom brackets. It seems that they would also work with bottom brackets from other brands meant for 30mm spindles, but note that Hope has very specific requirements for the over bearing width of the bottom bracket once installed in the frame. Specifically, the RX cranks need an over bearing width of 91mm +/-1mm. For me on a Lauf True Grit, that meant installing a silver 1mm spacer under each cup of the BB to get it to 90.42mm.

Frustratingly, the Hope threaded bottom bracket has its very own 16 notch tool pattern making it require yet another specific tool. There are currently at least seven different bottom bracket standards all using 16 notches, and the Hope BB stands alone with a 48.9mm cup diameter and 47.2mm notch diameter. Because of this, you’ll need a Hope-specific tool like the HTT0015 socket tool above which Hope sells for £20 (roughly $26).

Personally, I was disappointed to see that the hope tool uses a 19mm nut to drive the tool instead of incorporating a 3/8″ or 1/2″ drive to directly connect to your torque wrench or ratchet. I’ve been conditioned to expect the sockets to stay in place so I found myself constantly dropping the Hope tool on the shop floor because I would keep forgetting that it wasn’t actually attached. It’s also just more fiddly to use since you have to add another layer between your torque wrench and the bottom bracket. Hope says that they’re considering updating the tool to a 1/2″ drive which would be a very welcome change. In the mean time, I would highly recommend the OSBB “HP” tool from Abbey Bike Tools. It’s a little more expensive at $40, but it has a 3/8″ drive and machined finger splines so you can turn it by hand when needed. As far as I’m aware, this is the only other tool available for the Hope 30mm threaded bottom brackets.

Proprietary standards aside, I’m going to give Hope a pass since the bottom bracket is really good. They seem to know their way around making bearings last in terrible conditions – they are based in the UK after all. The bearings spin incredibly smooth, yet seem to offer impressive shielding against the elements and durability which is everything you want from a bottom bracket.

Once the crankset is installed and the 10mm bolt is torqued to 50Nm, any play in the bottom bracket is removed with a threaded lockring. This is why the over bearing width is important.

Pro Tip: My crankset shipped with the wrong instructions specifying an over bearing width of 96.5mm +/-1mm (it should be 91mm +/-1mm, see above). You can Find the proper crankset instructions at the bottom of Hope’s web page under ‘Manuals and Diagrams’ just to be safe.

Q-Factor

Visually, it looks like the RX crankset has a wide q-factor, but according to the spec it must be an optical illusion. The RX cranks have a q-factor of 149mm, which is 2mm narrower than say, a Shimano GRX crank at 151mm. They do appear to have a flatter profile with a wider stance at the BB than many road cranks, so if you have bad heel rub already, I could see it being a potential issue here. My cranks have some marks over top the RX logo, but I’ve also been riding them with clunky winter boots which rub on all of my cranksets. With normal riding shoes, I have no issues with any rubbing, and there is plenty of room between the crank and my shoe.

Weight

All that internal weight saving effort seems to have paid off. The 172.5mm crankarms, spindle, hardware, and a 40t chainring come in at 580g. For context, the Easton EC90 SL cranks in 175mm with a 42t chainring are not that far away at 518g for the same parts – and Hope did it without a lick of carbon fiber. The Hope BSA30 threaded bottom bracket adds another 94g.

How Much?

Normally, I probably wouldn’t go for a bright red crankset, but in this case with a bright red bike, I figured why not? The arms, rings, and BB are also available in black, blue, silver, purple, and orange so the choice of matching, clashing, or blending in is up to you.

Crank arms are also offered in 170, 172.5, or 175mm lengths and are priced at $380 without a spider, or $415 with the spider. The chainrings are sold separately at $70 each. The last piece of the puzzle is the bottom bracket, which in this case is the 30mm threaded BB priced at $120.

Overall, the RX crankset has lived up to the Hope related hype. Other than a few hiccups during the install process, the crankset has performed flawlessly. It feels just as stiff as the best carbon crank, and has the potential to be more durable. As an added bonus, it looks incredible and offers yet another way to customize your favorite build.