When it comes to cyclocross bikes we get the opportunity to review a lot of different bikes with different builds. When Milwaukee Bicycle Co. approached us about a potential review on their Mettle CX, there was one thing that made it stick out – U.S. made steel. In addition to making hand built frames available at more attainable prices than full custom, Milwaukee takes it a step further and offers a custom build program that includes 20% off the parts from their shop.

That makes the Mettle very attractive, but what’s it like to ride? Surprisingly fast, it turns out…

Started in 2002, Milwaukee Bicycle Co. is the brainchild of Drew Triplett who was previously an employee of Trek. After working his way up from the bottom with a broom in Waterloo, Drew left Trek and ended up at Ben’s Cycle and Fitness in 2001, which in turn became the home of the Milwaukee Bicycle Co. Now with 10 different bikes, all of their steel frames except the Grit and baseline Bruiser frames are made in the USA by Waterford Precision Cycles.

That results in bikes like the Mettle with a full True Temper OX Platinum steel tubeset that is equal parts modern and classic. Built with classic round tubes, the Mettle adds a tapered carbon fork and disc brakes to bring the bike up to competition speed with a geometry that was developed with their race team. Claimed frame weight is listed at 4.4 lbs (2000g) for a 56 cm. Our test bike was a 53cm and at its lightest configuration was just over 17lbs complete with Xentis Squad 4.2 carbon tubular wheels.

Given that the review bike we were sent wasn’t the most recent frame to be built, the finish options have changed a bit – but in a good way. While the paint on our tester was beautifully done, their new powder coat finish with brazed on stainless logos is not only easier for them to produce more quickly, but it also looks incredible. The orange bike on the right highlights the new finish at Ben’s Cycle and Fitness. As part of their custom build program, customers can choose any Prismatic Powder Coat color they want free of charge. Milwaukee gets the frames from Waterford raw and then brazes on the logos in house which allows them to then send them out for powder coating to the customer’s choice.

For the review, Milwaukee Bicycle Co. had this particular Mettle already built up with an Ultegra 2×11 drivetrain, Shimano mechanical disc brakes, a Whisky carbon cross fork, and custom Velocity wheels with Shimano Centerlock hubs. Milwaukee does have their own full carbon fork to go with the bike as well that weighs in at 550g, with a 395mm axle to crown and 49mm rake. As mentioned, all of this is inconsequential given the fact that you can either buy the Mettle as a frame only, or as a complete custom build with the components of your choosing. Due to my injury at the time, while I was riding the bike I swapped the front chainrings for a single Wolf Tooth Components narrow-wide chainring, and limited the front derailleur so it wouldn’t rub. I couldn’t operate the front shifter at the time, but I didn’t want to take off the front derailleur completely because I was sharing the bike with Robert who raced it with 2x (below). While the 1 1/8-1.5″ tapered head tube is a more modern touch, other details like the 68mm threaded BB shell and 28.6mm clamp on front derailleur remain unchanged. Also note the rear brake cabling is kept external and run on top of the top tube for easy shouldering.

The one area of the frame that may be polarizing would the choice of dropouts. The Mettle uses 135mm QR spacing for the rear with an ISO disc mount capable of running 140mm rotors. QRs keep the wheel changes relatively quick especially with the stainless plate brazed to the chainstay so you don’t have to worry about the rotor damaging the finish. However, thru axles are generally more secure for disc brakes and we’ve found them to be more precise in rotor placement for repeated wheel changes. Ultimately, the QR dropouts of the Mettle were fine and didn’t seem to affect the performance of the bike at all – just make sure any wheels you’re planning to run have a 135 QR end cap option. Speaking with Milwaukee Bike Co. there are no immediate plans to change the dropouts in the future though it could be done relatively easy if they had enough demand.

I was hoping so hard that I would be ready to race by the last local event of the season, but unfortunately it just wasn’t meant to be. I just couldn’t hold onto the handlebar strongly enough to guarantee I wouldn’t fall off just riding in a straight line, let alone to race cross. So I handed the keys over to my friend Robert who works and rides for VeloFix Cincy. Robert has always been a ripper on the mountain bike, but hadn’t taken up cross until this year. With a handful of races under his belt for the 2015/2016 season, he jumped on the Mettle for the last race of the season.

After a questionable start and nearly washing out in the first real turn, Robert was able to pick his way back through the entire field to take his first win! I’d like to think it was all the bike and wheels, but realistically I know the rider had more to do with the result than the bike. However, considering that morning was the first time Robert had ever ridden it, it certainly passes for a cross bike that is easy to jump on and ride fast right away. It was clear that Robert made up a lot of time in the more technical sections and turns than on the flats, which can be attributed to the Mettle’s willingness to be really driven through a corner. Milwaukee’s Paul Warloski mentions how the Mettle being less stiff than many of his carbon race bikes seems to make the bike easier to handle through technical sections of the course and after riding it myself I’d have to agree. Perhaps it’s the fact that it’s more forgiving than a super stiff carbon bike, but whatever the reason the ride is fantastic. I will say that adding a stiff set of carbon wheels to the mix though really increases the race worthiness of the bike. Going from the stock aluminum clincher wheels to the Xentis tubulars completely transformed the feel – as many carbon tubulars would. For reference, Robert and I are close to the same size – 5’7/5’8″ with Robert running a slightly lower saddle height. I found the 53cm to fit very well with almost no toe overlap which can be a problem in cross bikes my size.

As my time on the bike proved, it also doubles pretty well as a dirt/gravel/road bike. The geometry is definitely suited more towards cross racing but the addition of two water bottle cage mounts and fender mounts shows that Milwaukee expects this to be ridden more than just on the race course.

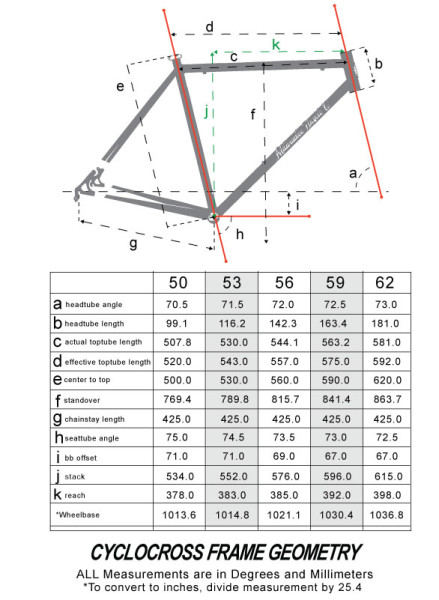

Bottom line, if you’re looking for a U.S. made steel cross bike with a custom build (and don’t mind 135mm QR dropouts), the Mettle CX is sure thing. Available in 50, 53, 56, 59, and 62cm stock sizing, framesets start at $1300 with the frame in your choice of power coat color and Milwaukee Bicycle Co. carbon fork.

If you happen to be in or around Milwaukee, you can actually stop into Ben’s Cycle and Fitness to see the bikes and to talk to Paul or Drew in person. A long time fixture in Milwaukee, Ben’s Cycle and Fitness was started in 1928 by the current owner’s grandfather Ben. Over time the shop has expanded and eventually moved across the street from the original location and includes the most amazing warehouse I’ve ever seen – a reclaimed Vaudeville theater. Whether you’re in the market for a new bike or not, it’s well worth the visit.