When trying to squeeze the very last bit of weight and performance out of a bike, some people turn to titanium bolts. Being just 56% of the density of steel, titanium can cut a lot of weight out the large amount of steel bolts that hold your bike together, yet Ti can be weaker when cut into bolts, giving safety concerns.

ProTi has a solution for that. By forging the bolt and not cutting it, the metal aligns itself with the end product better, creating a part that has all the weight savings of titanium, but retains the strength of a steel bolt. We took a first look at them in November, and recently picked up a kit to see how they stack up.

Ti bolts do not come cheap. ProTi’s FFR technology makes these some of the most expensive, but the forging makes them stronger so they can be used in more places. Take a look inside to see the cost vs weight savings, and decide for yourself if they can help make you faster…

At first glance, the ProTi bolts are well finished. We got our hands on a stem kit (6 bolts, M4x18mm) for $42, A brake caliper kit for two wheels (4 bolts, M6x16mm) for $32, and a set of disc rotor bolts for two wheels (12 bolts, M5x10mm) for $90. At this price, saving weight is just expected, but these things better look amazing too. Mounted to a Thomson stem, they do add a bit of visual beauty that is not present with the rough-finished stock steel bolts.

The $42 bolt kit installed on the Thomson 70mm X4 stem saved 10 grams. Most weight weenies try to shoot for $1 per gram of weight savings, so these are quite expensive. However, with their forging method that dramatically increases strength, these cannot just be simply compared to other CNC-machined Ti bolts.

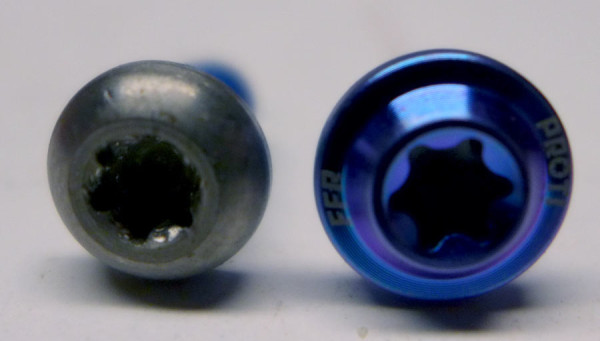

Taking a close look at the bolts, you can see the finish quality present on the ProTi peices, as well as their strength. The two rotor bolts above were both installed once, and then removed. The titanium bolt on the left is what is included in a large manufacturer’s high-end brake, and is a standard machined titanium. I have found that many of these cut Ti bolts start to deform around the tool, even when just bringing them up to recommended torque. The ProTi bolt shows a better quality finish, as well as no deformation from an install and removal.

Knowing that these bolts cost a lot of money, and they need to be presented in a way that is worth that cost, the ProTi bolts come well packaged with a decal and instructions. While none of this matters once the bolts are installed, its nice to know that your expensive bolts are not coming in just some tape and bubble wrap.

Above, the ProTi caliper bolt kit ($32) is compared to a set of Shimano steel caliper fixing bolts. A savings of 17 grams is not too bad, and it shows that the larger bolts on the bike have a lot bigger return on investment for weight savings with titanium.

When looking at brake rotor bolts, there is a savings of just 5 grams per wheel. This means that at the rotor, the $90 kit for both wheels will save you 10 grams, or about 3 times the cost for the same savings as the caliper bolts. Once you get down to this level of weight savings, you really need to decide how important each gram is to your ride.

Titanium also has other properties besides a low weight that may be of interest to some riders. Ti does not corrode, and if you ride in salty environments, they may help keep your components from becoming permanently fused by ferrous oxide. The ProTi bolts are also available in standard Ti color, gold and blue. If you want to add a spice of color, these can be used in areas where anodized aluminum bolts are not strong enough.

The stem kit saves 9-10 (it was 10 when measured installed on the stem) grams for $42. The stem kit is where I begin to question the value of titanium bolt upgrades. Stems go through a very robust testing regiment to pass international standards, and the bolts can play a large part of the overall integrity of the stem. It is not just about the bolts being strong enough, but about being an entire system with the stem. Too much stiffness in the bolt could transfer stresses in ways not seen before, leading to a failure, or too little strength in the bolt could cause a direct failure. Even though the ProTi bolts are probably strong enough themselves, I’m not the kind of person that is too keen on risking another broken collarbone to save 9 grams.

The idea of replacing bolts with Ti to save weight has been argued for decades on bike forums across the internet. A definitive agreement will never be reached amongst riders whether geeking out the last gram of the ride, or a pre-race visit to the bathroom is going to provide a greater benefit. Obviously, these bolts are not for everyone, especially if you are on the “drop a deuce and ride” side of the argument, but if you love nerding out about the weight of your ride, ProTi FFR bolts are probably the best quality titanium out there.