I had a pretty extensive conversation with the folks at Wickwerks at Interbike back in September as I was somewhat intrigued by their new option for junior gearing that would make needing to order special-sized cassettes a thing of the past. Even more so was that they were “successfully” running a 53 + 34 tooth chainring combination they developed, which I knew from past experience shouldn’t work well. I mean, you could drive a Prius through the gap between the small chainring and the front derailleur cage!

They sent me 2 sets of their Road Ultra Wide rings to try out on both mechanical and Di2 systems to see if how they worked…

Recently we saw SRAM say goodbye to the front derailleur, but nothing probably excited bike mechanics around the world more than the over-due extinction of the chain-bending Triple chainrings on road (and most mountain) bikes. Preventing chain rub was an art with road Triples, so when the Compact crankset was developed in the early 2000’s along with 9 speeds and bigger cassette offerings, despite some initial resistance, the Triple slowly went away.

As soon as Compact came about, the racer crowd became interested in their application on tough mountain climbs, but in no way were they about to give up their 53t ring. I even recall when a friend and “expert internet mechanic” ordered a 110bcd 53 tooth ring and asked me to get it working with his 34. Needless to say, I could have shifted it better with a dull butter knife, as the chain would just bind rather than climb up the ring. The front derailleur simply didn’t have long enough throw or the right angle to get the chain up there.

It was a complete disaster, so my suspicions were strong with Wickwerks’ Road Ultra Wide rings. I thought they may have actually gotten it to work, but if it wasn’t “smooth” or I had to baby it… it wasn’t going to cut it.

The back of the big rings have an extensive amount of detailed machining on them that is as beautiful as it is functional. Termed “Bridge Technology”, the ramps are designed to carry the chain up rather than have a pin catch the chain once the front derailleur pulls it up and over. Made of CNC’ed 7075-T6 with a MIL Type 3 True Hard Anodize coating, the rings should wear well.

Though the 53/34t Wickwerks ring isn’t heavy so to speak, it’s hard to compete with Shimano’s hollow forging technology, adding on 55g in the swap.

Compared to the Mid-Compact Dura-Ace 52/38t rings that came on the bike, the machining on Wickwerks’ “Road Ultra Wide” rings is far more aggressive. They also don’t use pins like Shimano, so lets take a look at what they came up with and how it works.

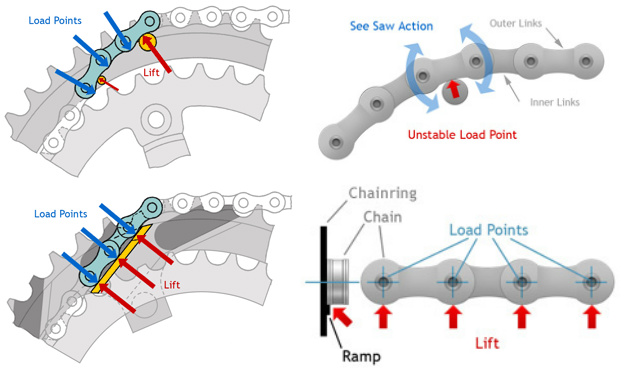

Up top is how a typical chain gets lifted using pins or grab points. Wickwerks uses ramps that extend from where the small chainring is all the way to the teeth of the big chainring. Like in my little experiment some years ago on this broad setup, the derailleur can’t effectively push the chain high enough for the pin to grab and carry it the rest of the way up. Because the pin setup catches the middle of the chain’s link, the rocking of the pin prevents the chain from continuing an upward path. As you can see in the diagram and the comparison between the two brands, the ramp on the Wickwerks grabs the chain instantly and virtually carries it up to the top while the derailleur just holds it against the ring. Though a pin system has proven to work fine, when there is that much separation between the two ring sizes (53/34), it just doesn’t work.

You can see in this pic where the Wickwerks’ chainring has a pronounced shelf that the chain sits on during its journey to the top… and of course that southern pollen. So how does it perform?

Setting this up seemed easy enough, but it was a little harder than first expected. Maybe harder isn’t the word. Tedious is more like it. I literally had to make microscopic adjustments that were made difficult because the ever so slight movement when tightening the front derailleur down would move it just enough to cause rubbing. Ironically the Di2 setup was harder as a simple barrel adjustment on my (personal) mechanical Ultegra bike fixed it in a jiffy. Regardless, two beers in, all was fine.

Come ride time, I took Fuji’s Di2 bike out first (because my pedals were still on it from last week’s review). Hitting the first slight descent, I tapped the shifter and nothing out of the ordinary happened. A simple flawless shift as if nothing was changed. It was a confident smooth shift, just as it should be on this caliber of bike. Shifting back down… well, this took some getting used to. It was a great shift, but going from a 53t to a 34t (that’s almost 20 teeth), is something I’ve never experienced. My 25 years of down shifting to the small ring while almost simultaneously shifting two clicks down to a smaller cog in the back was not sufficient. The step was big going from little to big, but much more noticeable when your cadence is way too fast. Switching to the bike with mechanical Ultegra, I thought maybe with a lazy shift I could get the the rings to fail. Although I made it rub a little, as soon as I pushed it a little more, the ramp on the Wickwerks snapped it right up.

Overall, Wickwerks’ Road Ultra Wide rings worked really well. It didn’t perform any worse than the stock setup, and I found that impressive considering the challenges that configuration faced. Though, I did find myself having to shift the rear 3 to 4 times, rather than the standard 1 to 2 times on a 53/39t setup, and each time I shifted the front it was a bit annoying. But I eventually settled right in. If you ride where there are a few long grueling climbs, or you could just use a little extra range to ease the burn, the Road Ultra Wide rings will suit you really well.