Hope’s had drawings for a bike since 2005, but when they made the decision to start doing carbon a couple years ago, that made the dream seem possible.

The frame has a working title of HB.211, which refers to Hope and their hometown, and the date (February 2011) when they started on the journey to in house carbon fiber fabrication. The bike uses a Horst link design, but the type of suspension is secondary to what this project means. It’s a bicycle that’s built around their components, which is different than usual where the component company is working around someone else’s bike. That meant they could design it to optimize the parts, which led to some very interesting one-off components indeed…

Starting at the rear, they designed it with a radial brake mount, which required an entirely new caliper. Note how the HB.211’s brakes (left, green) have mounts that are pointed in a parallel line from center of axle to center of brake. Contrast that to current designs (right, orange), whose mounts move outward at an angle. The prototype design makes it easier to size a rotor up or down since it’s all moving directly outward from the axle’s center. Not that there’s any performance benefit, but it looks cool, and that’s how they do it in moto.

Note the difference in the caliper bodies to accommodate the different mounting angles. Click to enlarge.

The rear axle spacing is 130mm, with a 17mm diameter thru axle slotting into a 25mm frame interface. Why? They wanted a narrow rear end for better clearance for ankles, rocks, etc. They did this by moving the hub’s disc brake mount inboard (compare prototype green to standard orange), closer to the spoke flange. The spoke flange spacing is the same as normal, so that and the massively oversized axle system keep the wheel very stiff.

Even with the narrow 130mm design, they could give it Boost chainline spacing on the driveside by making the rear triangle asymmetric.

The rear triangle is machined in house then hard anodized locally. The front triangle is molded in house, and they machined all the molds themselves, too.

This prototype bike, and the project itself, isn’t about trying to reinvent the suspension design. They just wanted to make the bike and component interface better.

They created a chain guide interface that doesn’t rely on ISCG standards, but bolts in above the chainring. It’s just the way they envision things should be, not necessarily how everyone should do it. It was much an exercise in learning more about using carbon fiber as anything else.

They’re making ten of them for employees to ride and test, at which point they might tweak things as needed and design the molds to be production ready and make more. There’s absolutely no timeline, but ultimately they probably will look to sell a complete bike.

Speaking of carbon, they just started shipping their new carbon seatpost this month, which is their first production carbon part made in their UK factory.

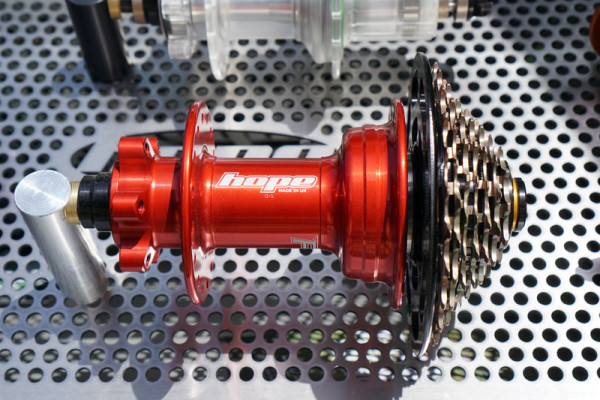

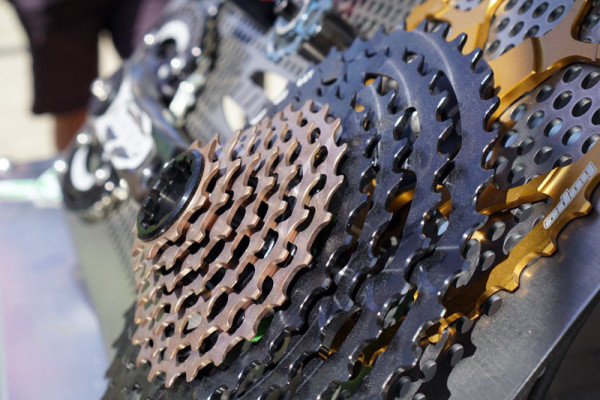

Other parts, like their DH cassette and hub and the wide range 10-44 cassette that were shown at Eurobike are also now in full production. Check our coverage here for full details. The cassette’s 10-tooth small cog requires a special freehub body that they make for their hubs.