Made-in-Germany steel bikemaker Sour wanted a new carbon gravel fork for their adventure bikes, but they tend to go a bit hard off-road. So, Sour created The Business – a fork developed to pass the toughest tests in the industry so you can ride wherever and as far as adventure takes you. Apparently, Sour’s The Business is also the first fork to pass independent test lab EFBE’s grueling Tri-Test – a 3-part test going far beyond basic test standards to better address the way cyclists push the limits with modern bikes off-the-beaten-track…

Sour Business ultra-tough carbon gravel bikepacking fork

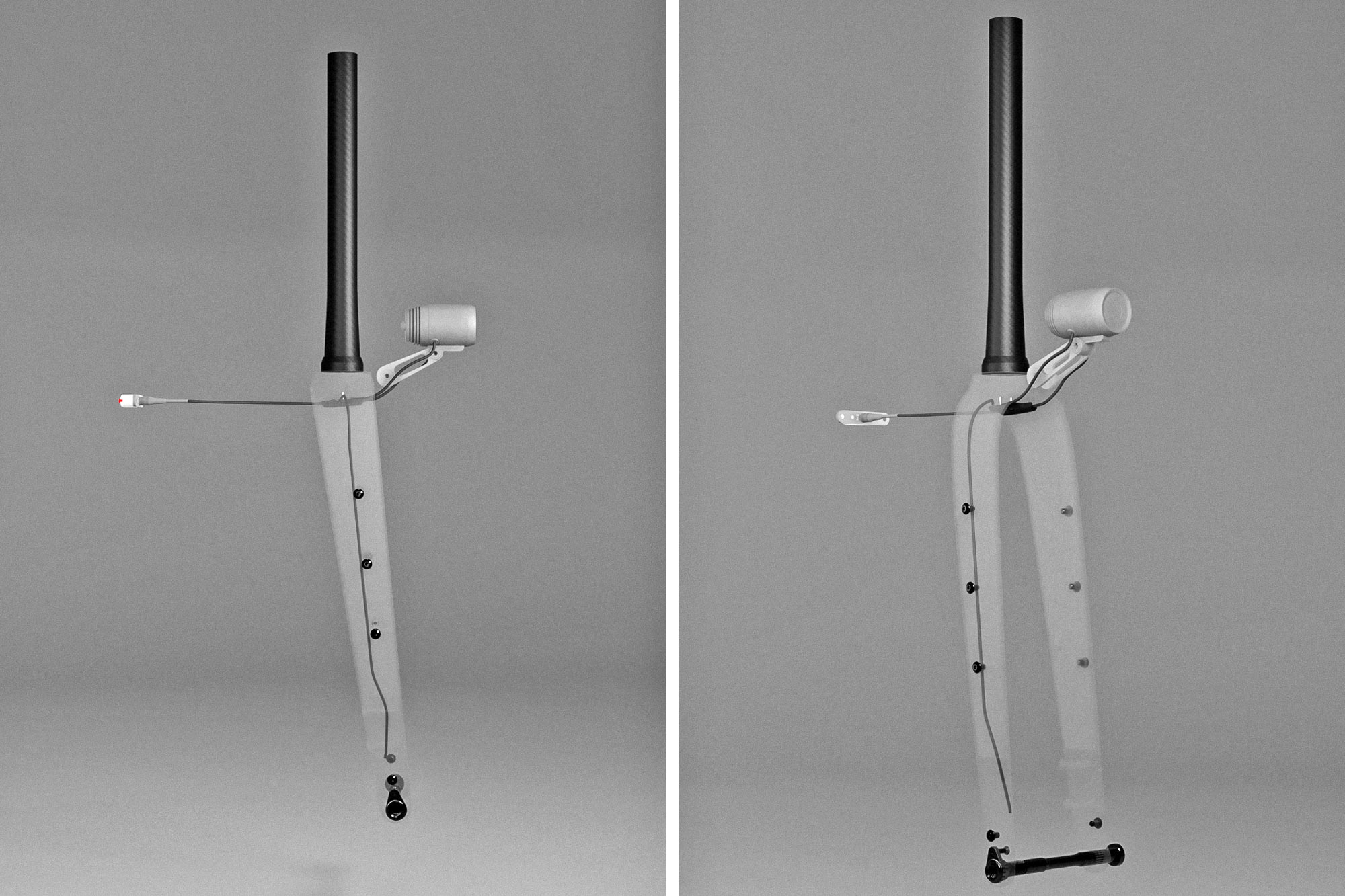

On the outside, the new Sour Business fork looks pretty standard for a well-featured modern carbon gravel bikepacking fork. But Sour sweated the details even more, to bring adventure riders another level of strength and durability, so it can go anywhere you dream to roam.

Why is it called the Business fork? Well, last year Sour made a heavy-duty BMX-style steel bikepacking fork for their Pasta Party off-road adventure 29er – dubbed the Party fork. This new carbon model is still adventure-ready, but a lot lighter and likely to be ridden quite a bit faster… all business.

Why the EFBE Tri-Test?

When a company wants to really see just how tough it can build a bike or bike component, for almost thirty years they have often turned to the trusted EFBE test lab. Their benchmark Tri-Test doesn’t stop at conventional limited bicycle testing standards, but subjects a component to tougher fatigue tests, maximum load tests, AND overload tests – all designed to push a new component to the extreme and see how it really would hold up to a lifetime of actual riding and abuse. The Tri-Test has truly become the new benchmark for design engineers looking to create the toughest bikes and components.

The carbon Sour Business fork was tri-tested to cyclocross & gravel’s condition 2 back in February – passing EFBE’s bending fatigue test, brake mount fatigue test, static bending test, static brake test, and maximum load/ overload test.

Want to learn more about what EFBE does? Read more at their Tri-Test process description.

Tech details

The full carbon Sour Business gravel fork features a 1.5″ tapered steerer, semi-internal brake line & dynamo wire routing (not through the steerer), lots of mounts, and 700c x 55mm max tire clearance. The dynamo routing in the right fork leg exists through a 3d-printed guide under the fork crown to direct wiring to a front light and back to the frame for a taillight, too.

The mounts include 3-pack anything cage eyelets on each leg, with the lower of these 3 eyelets going entirely through the leg so that it can support a low-rider rack together with the mount at the front of the crown. That means that each cargo cage could carry up to 7.5kg per side, or a low-rider rack connected at 3-points can haul up to 15kg. The fork also gets fender mounts down at the bottom too, and a replaceable threaded insert for the 12mm thru-axle.

The fork gets FM160 direct flat mount disc brake mounting for increased strength, and fewer parts that can fail. That does mean that it mounts a standard (typically 140mm) caliper through the fork leg without an adapter, much like a rear flat mount brake. But it does mean that you can’t run smaller than a 160mm rotor, and for example, if you use Campagnolo brakes, you need to use the 140mm caliper, not the 160mm direct mount front caliper.

The fork has a 403mm axle-to-crown length, and 45mm offset. Sour claims a weight of 550g – the fork with 300mm uncut steerer tested by EFBE weighed an actual 552.9g according to their testing report.

Sour The Business fork – Pricing & availability

Technically, the new Business fork was meant to be the new standard carbon fork option for Sour’s 1050€ made-in-Germany Purple Haze gravel frame, adding just 250€ on top of the frame, and even including a headset. A pretty good deal, I think.

And Sour offers a lot of painted-to-match and even custom painting options like on this customer’s crazy custom bike – feel free to discuss that cut-in-half-bar clamped into a wacky custom steel stem in the comments.

But, Sour recognized that custom frame builders and folks already with a more basic fork, might want to get an off-road adventure-ready upgrade, too. So, you can also buy one separate from a Sour frame for 450€. It’ll be up on their webshop soon, but in the meantime, you can reach out to them directly here to order one.