Last week Cannondale debuted an 8th generation Lefty Ocho XC fork, paired to their new F-Si hardtail. From the outside, its move to an industry standard steerer & single-crown were highlights, but inside the fork (strut!) got a total overhaul promising more suppleness & handling precision. So what makes Cannondale’s unique Lefty design both supple & precise compared to regular two-legged lightweight XC forks?

Inside the 100mm travel Cannondale Lefty Ocho XC fork

Without a doubt the one-legged mountain bike concept has been a decisive issue since Cannondale’s first Lefty fork was introduced back in 2000. (Yes, since this is a suspension technology article I should be clear that the Lefty is technically a strut since it only gets a single leg. With that out of way, I’ll go back to calling it a fork since that’s what we are comparing it to.) But while haters will joke about the missing leg, even those who adopt the Lefty have to adjust their brain to looking down and seeing just one leg.

Those who have ridden the Lefty know it is often touted as the stiffest XC race fork on the market, so much so that this latest Lefty Ocho iteration actually detunes some of that signature stiffness for more predictable handling.

We sat down with Cannondale’s suspension designers & engineers to explain what makes the new Lefty Ocho tick, then we hopped on the new bike with them to get a feel for it.

Mountain Bike Fork Stiffness & Impacts on Bike Handling

Mountain bike fork stiffness can be broken down into three components, effectively the X, Y & Z axes about the headtube – Torsional flex, Fore/Aft flex & Lateral flex. Each aspect lends its own character to the ride, but generally more stiffness is better for predictable handling and smooth suspension operation. Specifically a fork that flexes front-to-back or side-to-side makes the bike harder to control, and especially with a traditional two-legged design, flex in any direction can increase friction in the telescoping bushings & seals.

Torsional Stiffness

Maybe counterintuitively (or because Cannondale was compensating for rider uncertainty) the Lefty has always been a benchmark of XC race level stiffness. In fact, the Lefty has sometimes felt as being too stiff, so Cannondale dialed back the torsional stiffness of the new Lefty Ocho by 14%. The engineering team says this lets the new fork track more predictably through rough, choppy trail & rock gardens – allowing the front wheel to deflect around big impacts instead of just bouncing off. Looking at the actual test figures Cannondale showed us, the new design places the Lefty Ocho on par with SID WC for torsional stiffness (actually 2% under the SID), both more than 1/3 stiffer than the 32 SC Factory 29er.

Fore/Aft & Lateral Stiffness

Front to back the new Lefty claims to be almost 18% stiffer than the SID and 8% stiffer than the 32. Side to side the Lefty is again the stiffest – 3% more than the SID & 7% more than the 32.

Cumulative or Overall Total Stiffness

Cannondale touts total stiffness as being the key factor in XC fork performance, simply adding up the torsional, fore/aft & lateral stiffness numbers. That might be an oversimplification, especially since the torsion figure where their fork is most flexible relatively, seems to actually improve ride quality. In any case cumulatively the Lefty Ocho looks to still be overall 9% stiffer than the slightly heavier SID World Cup, and 11% stiffer than the slightly lighter 32 Step Cast.

So how does that happen? How is the Lefty stiffer with just one leg?

A couple of things come into play here. First, since the Lefty is an upside down fork, the smallest diameter of the fork (the same 32mm sliding stanchions for Lefty, SID & 32) is closer to the axle at the end of the cantilevered arm. As opposed to having the narrowest element far away from the impacts coming through the wheel like a regular fork. Next, since there is only one leg, one stanchion, the Lefty can build in more material to resist flex. But that doesn’t answer it all, because a fork needs to be stiff, yet still slide smoothly.

Stiffness through Smooth Telescoping Action

Most telescoping forks rely on bushings that maintain a tight fit, but smooth sliding of the stanchion. That generally works well, but creates some friction that a bump has to overcome to move the fork. Also bushings tend to distribute the load over a relatively short area (around 2cm for example).

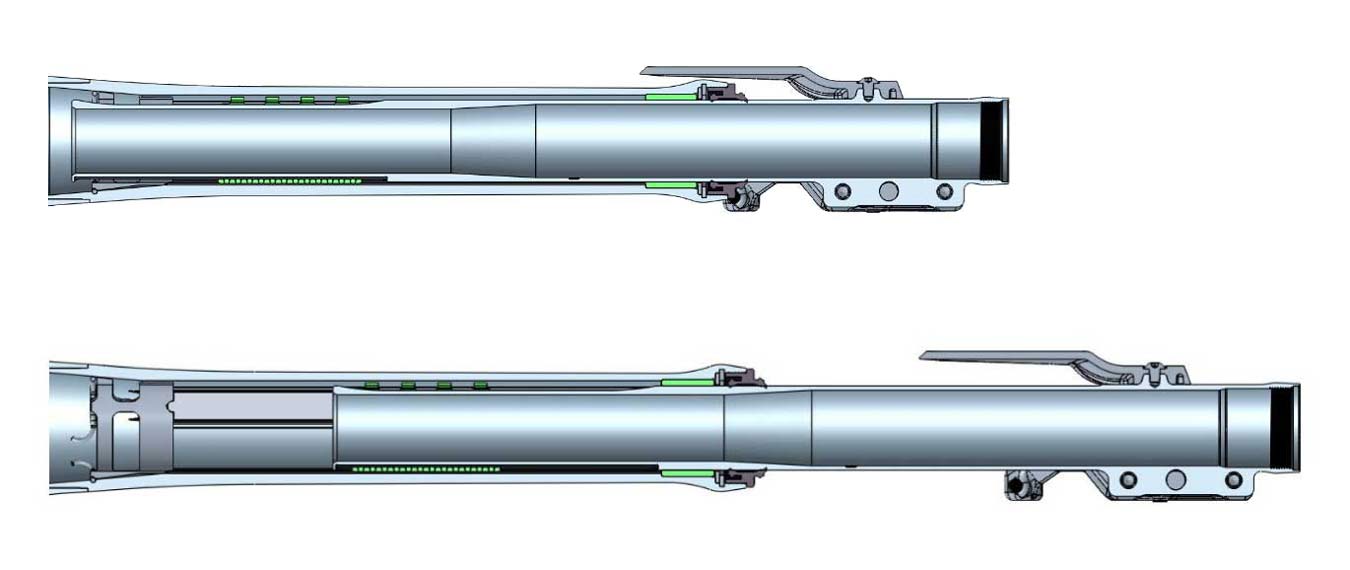

The Lefty does use a bushing at the lower contact between the stanchion and the upper/outer tube where the forces are lower, but uses a widely spaced ~7cm long set of needle bearings higher up in the fork to more evenly distribute forces.

The Lefty Ocho also moves to a new 3-sided design vs. the previous 4-sided. Basically it comes down to the fact that when you engineer a 4-sided system to take loads, it kind of needed to be overbuilt to provide the desired stiffness, resisting forces that came in at all angles to the bearings. With the new 3-sided design the ‘quartering’ forces that come in between two sets of bearings end up transferring the load across to the third bearing, then more perfectly aligned to resist movement.

Of course more bearing surfaces would generally be thought to provide more support. But then you would have to reduce the size of the bearings & bearing surfaces to fit within the tube, and likely end up with more weight.

Smoothness through fewer Bushings & Seals

One of the biggest issues a fork needs to overcome in order to have supple suspension is bushing & seal stiction. Smoothness is then a balance of the tight fit of the bushings & seals needed to maintain the stiffness of the fork. Cannondale says that just by dropping one leg they cut the number of bushings & seals in half (bushings & bearings in green above, compressed & uncompressed).

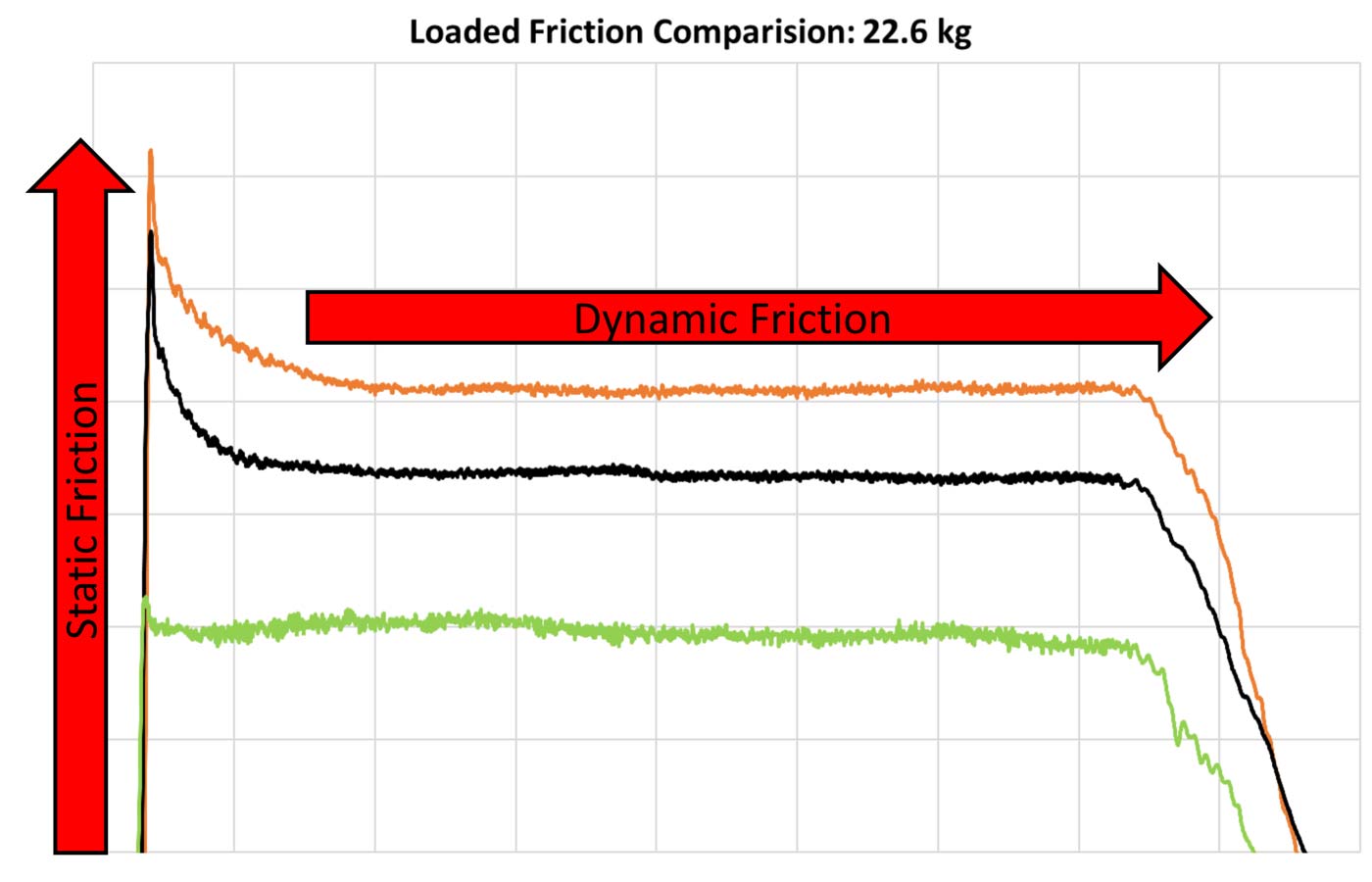

The Lefty with one leg cuts the number of those friction-creating elements again by replacing the second bushing (typically in each leg) and replacing it with needle bearings which roll more smoothly under load. The result is a single stanchion seal, one Glide Bearing bushing pressed into the machined end of the fork upper/outer tube, and one rack of needle bearings – and the lowest friction under load of the three World Cup level XC forks (Lefty Ocho in green above), at least 140% less friction when static & at least 75% less when the fork is moving.

To manage the three-sided telescoping slider, Cannondale now put those needle bearings into a single Delta Cage hinged plastic carrier that makes them easier to service. The design also let them use fewer of needle bearings overall, for both lower weight & less friction.The bearing cage and 3-sided design also allowed for lower bearing preload, again reducing friction in the fork.

Suspension Internals

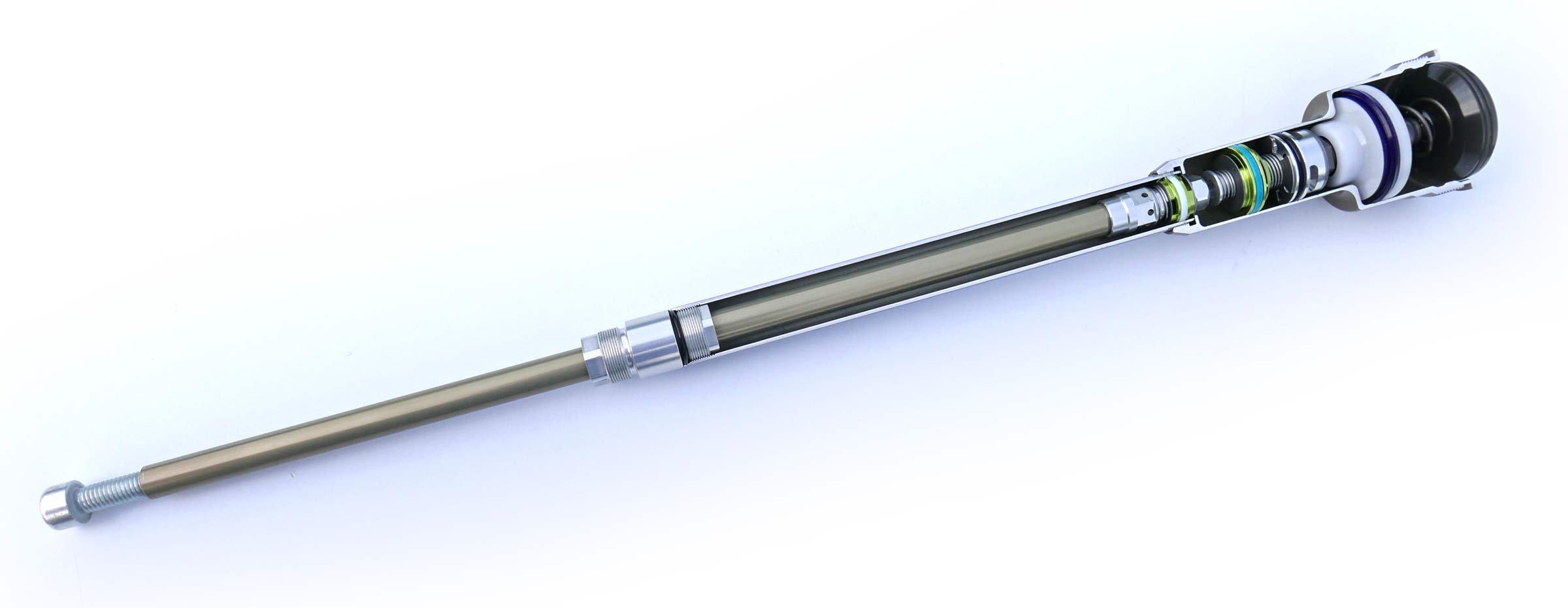

The Lefty forks have always had to combine air springs and hydraulic damping into a single leg, while the majority of dual legged forks spilt the two up.

Cannondale’s suspension engineers told us that got even more difficult when they decided to chop about 20% off the overall length of the fork for the new single-crown Lefty Ocho. So the internals got completely redesigned.

Chamber Damper

The new chamber hydraulic damper includes a simple 23-click dial rebound damping adjustment on the bottom of the fork leg and a 6 click compression adjuster on the top of the fork that then pairs with a cable remote lockout.

Inside is an Independent Floating Piston (IFP) that Cannondale says is designed to compensate for heat buildup and is self-bleeding.

OppO Air Spring System

The new OppO air spring design functions around the outside of the hydraulic damping cartridge, and uses a dimple machined into the internal of the upper/outer tube that automatically equalizes positive and negative air chamber pressure as you move the fork through its travel with a single Sidecar air valve (moved outside of the brake so any contaminant sprayed from the valve won’t end up on your rotor.

A stack of white plastic Ramp Clamp spacer at the bottom of the OppO air setup (around the plunger of the Chamber damper) then give you the chance to adjust air volume in the fork to tune the ride.

We did spend some time riding the new Lefty Ocho Carbon fork. Check out our first ride impressions here to see if the tech is backed up by trail riding & XC race course proficiency.

The fun never ends. Stay tuned for a new post each week that explores one small suspension tech, tuning or product topic. Check out past posts here. Got a question you want answered? Email us. Want your brand or product featured? We can do that too.