It wasn’t long ago that paranoid pros were looking for a way to cover their rotors to stay safe. While the hysteria has mostly passed, Alligator has come up with a new disc brake rotor cover that not only protects and vents the rotor, but actually channels air to blow right onto the brake pads to keep them from overheating.

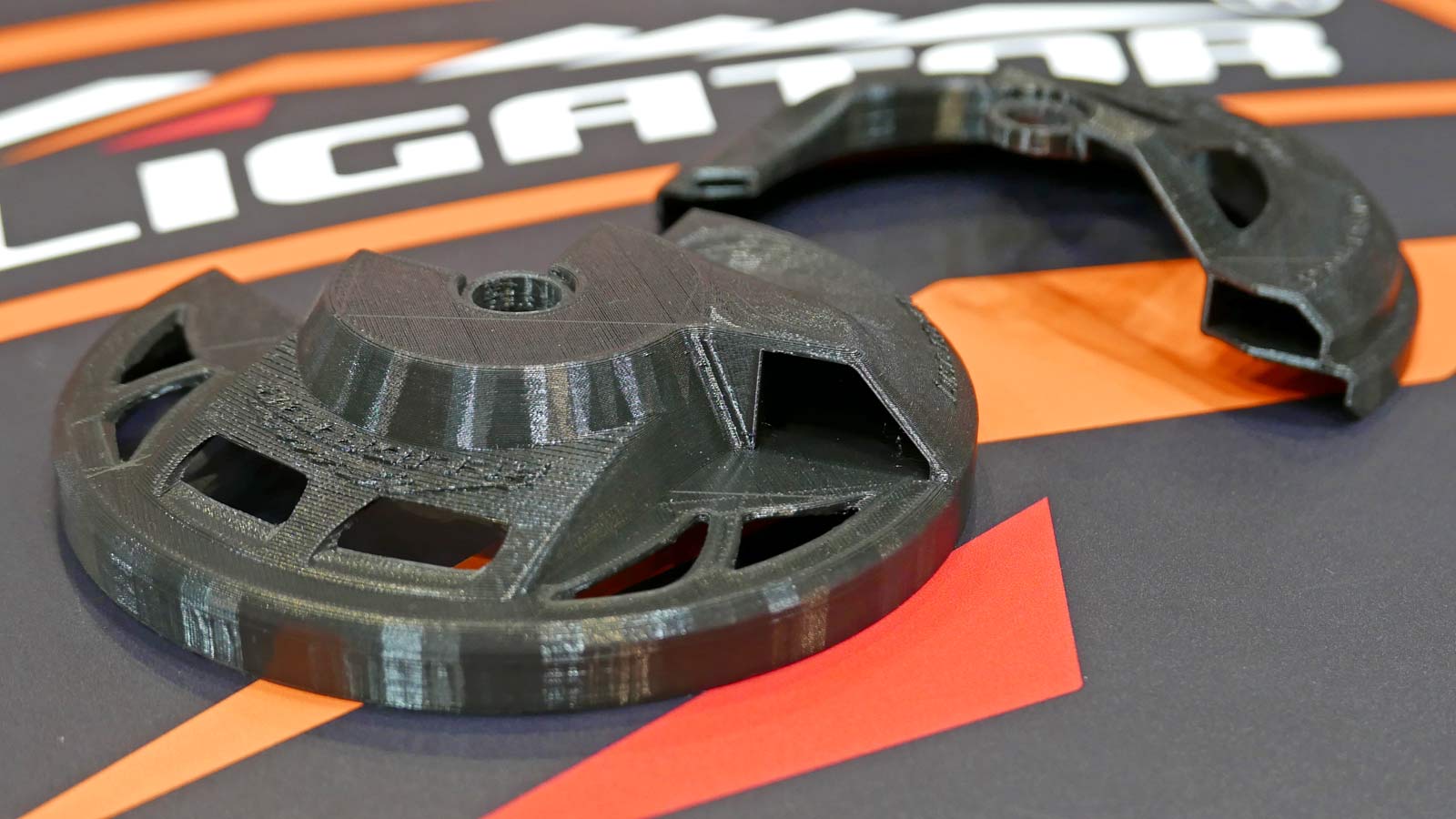

Alligator Disc Covers, prototype cooling rotor protectors

Alligator is probably first known for their shift & brake cables, but for a while have been coming up with creative alternative solutions for disc brake setups as well, always in a design that is quite affordable. Those vented orange Turbo Cooling disc brake pads are a good example, with simple twisted allow pad backing to allow for more airflow.

Now Alligator are taking a new approach to preventing your brakes from overheating with these new vented, cooling Disc Covers. The Alligator design proposes front and rear specific solutions that combine more common vented openings along the front, combined with a ducted air intake at the bottom of the rotor to compress air to be blown onto the brake caliper body, just where the rotor re-enters the brake.

These Alligator Disc Covers are obviously still rough as 3D printed mockups, but the design is quite intriguing. The front uses a larger forward-facing intake port to deliver the increased cooling capacity needed for greater front braking forces, then a smaller opening at the rear, which also prevents any shoe/heel interference.

Alligator says these 3D printed rapid prototypes represent the final shape of the Disc Covers. Production tooling is apparently almost ready for serial production, and the final parts will be constructed of ABS plastic to balance stiffness, durability, impact resistance, and most importantly of all – affordability. We couldn’t get a definitive answer if the final product would be a single piece, or more likely a two-part product that would be bonded together to enclose the cooling air channel.

Alligator says these 3D printed rapid prototypes represent the final shape of the Disc Covers. Production tooling is apparently almost ready for serial production, and the final parts will be constructed of ABS plastic to balance stiffness, durability, impact resistance, and most importantly of all – affordability. We couldn’t get a definitive answer if the final product would be a single piece, or more likely a two-part product that would be bonded together to enclose the cooling air channel.

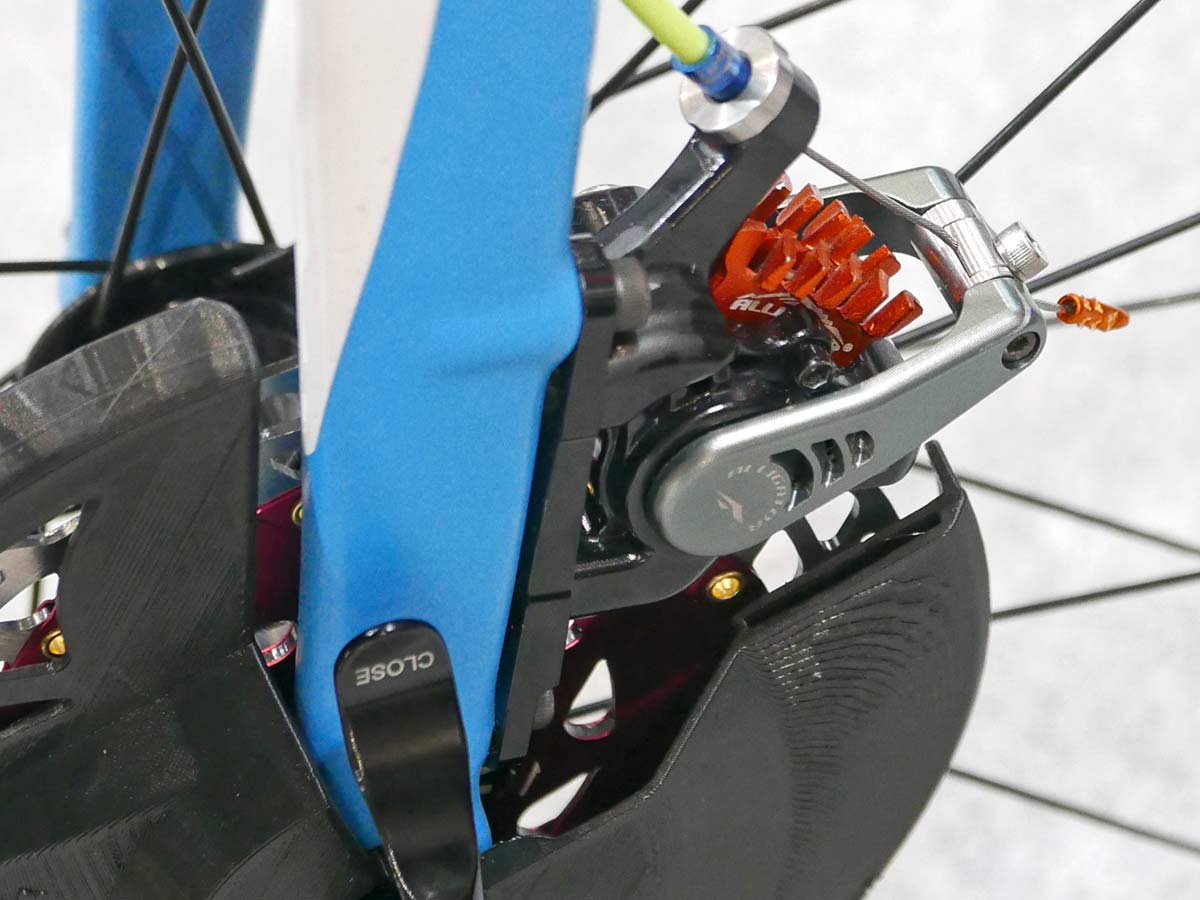

The idea is to let the rotor cool naturally as it spins through the air. The concept is not to just cool the rotor itself, but to direct airflow to a concentrated location on the caliper & brake pad just as the rotor rotates back into the caliper. That way heat dissipation in the system would continue as normal, with additional cooling at the point source of heat buildup to prevent brake overheating. Obviously that is an important feature for hydraulic systems, but also to maintain consistent performance in mechanical systems like seen here.

The idea is to let the rotor cool naturally as it spins through the air. The concept is not to just cool the rotor itself, but to direct airflow to a concentrated location on the caliper & brake pad just as the rotor rotates back into the caliper. That way heat dissipation in the system would continue as normal, with additional cooling at the point source of heat buildup to prevent brake overheating. Obviously that is an important feature for hydraulic systems, but also to maintain consistent performance in mechanical systems like seen here.

The Disc Covers are designed to simply slide over your existing thru-axle and be held in place when you clamp the axle tight (sliding off when the axle is removed.) It isn’t entirely clear how that might impact the need for longer axles to accommodate the additional material being clamped or any possible clearance issues with the thru-axle-to-dropout interface. We will have to wait for final products for more clarification on that.

The Disc Covers are designed to simply slide over your existing thru-axle and be held in place when you clamp the axle tight (sliding off when the axle is removed.) It isn’t entirely clear how that might impact the need for longer axles to accommodate the additional material being clamped or any possible clearance issues with the thru-axle-to-dropout interface. We will have to wait for final products for more clarification on that.

Pricing isn’t yet set either, but availability is already expected for the start of this summer. What we also know is that they should be made to work with 12mm front & rear, and 15mm front road axle standards, and versions will be available for both 140mm & 160mm rotors in front & rear specific designs.

As for those rotors themselves… they are another new product coming soon. The new Heat Sink rotors should be a relatively cost effective solution to improved cooling. The rotors are not a separate carrier and braking surface, but rather start life as a conventional looking flat 6-bolt stainless steel rotor, and then get a sandwich of thin formed aluminum cooling discs riveted around the core to offer more heat dissipating material.

As for those rotors themselves… they are another new product coming soon. The new Heat Sink rotors should be a relatively cost effective solution to improved cooling. The rotors are not a separate carrier and braking surface, but rather start life as a conventional looking flat 6-bolt stainless steel rotor, and then get a sandwich of thin formed aluminum cooling discs riveted around the core to offer more heat dissipating material.