There has been a lot of talk in both the industry, the media, and forums lately about the new mountain bike axle standard of 142×12. While there is an abundance of good information available, there are also a ton of misconceptions. Clearly there are some new concepts in play, though perhaps most alarming to the general public, is a perceived assault on the current standard: the 135x10mm (also known as 135 x 5mm, 5mm is the quick release diameter, 10mm is the axle, or drop out diameter) quick release rear wheel. Consumers are up in arms over the fact that there is a new “standard” that will obsolete their current set ups, only to force them into new wheels.

This thinking is understandable, but in reality, manufacturers have gone out of their way to make the new crop of mountain bikes backwards compatible, and offer hop up kits for current hubs to make the jump. When it comes to “why,” there is a lot to digest, but simply put – it has the potential to be better.

Get the full skinny on the fat axle, after the break!

Let’s go back. Way, way back, 1927 to be exact. Wing nuts were still used to secure bicycle wheels at this point, and it was here, on the side of the snow covered Croce D’Aune Pass, that Tullio Campagnolo would find the inspiration for a bicycle component that is still used today. After losing valuable time in a race, due to the inability to remove the wing nuts on his wheel because his hands were so cold, Tullio eventually designed and created in 1930, what we know today as the modern quick release.

While Tullio was certainly ahead of his time, and an inventive genius, he couldn’t possibly have imagined the manner in which mountain bikes are ridden today. Sure, manufacturing methods, and both frame and hub construction have improved, but essentially, many of us are still riding on a 80 year old design, originally conceived for road bikes.

Why Thru Axle?

As mentioned above, the current mountain bike rear QR axle system is horribly out dated. Due largely in part to the advent of disc brakes, modern suspension, and excellent tires, riders are able to bomb descents faster than ever thought possible in addition to catching some serious air time. The larger diameter thru axle allows for more strength, stiffness, and ease of use. Ever tried to explain to someone how a quick release works? It is much easier to explain how to use a QR thru axle by saying, “turn this until it stops, then flip this lever.” While weight is always a concern, the larger diameter of the thru axle allows for it to be made of aluminum which causes only the smallest weight penalty when compared with the average QR set up. Safety is also a foremost priority, so the fact that a thru axle is captured in the frame, virtually guaranteeing against wheel ejection is obviously a plus.

However, the goal of 142×12 wasn’t necessarily to improve stiffness, yet offer an easier to use interface for consumers. Traditional thru axles required the axle to be clamped both axially, and radially which was usually accomplished with a handful of pinch bolts – not simple. The hope for 142×12, was to create a system that could be installed easier than a quick release without any tools (once adjusted) and once installed would provide a safer method in which to secure the wheel to the bike.

Why the 12mm axle?

12mm refers to the diameter of the axle itself (the part that replaces the QR), how did manufacturers come up with the 12mm axle size? For starters, it’s been used for DH bikes for years, but more importantly it is basically the largest axle that will still fit through a modern cassette lock ring, and disc brake rotor. This becomes even more important, with the current experimentation with cassette gears as low as 9t. Obviously, consumers are already upset by the fact that there is a new rear wheel spacing, so the wise decision was made to accommodate current cassettes and rotors.

Why 142mm rear spacing? Wasn’t 135 good enough?

This is perhaps the most controversial issue of the entire transition, as it involves a new “standard.” This measurement is the actual width of the hub from end to end, and standard MTB rear spacing has been 135mm. If you were to compare the same wheels, with one being a 135×12 hub, and one being a 142×12 hub, they would have the exact same measurements aside from the OLD (Outer Locknut Dimension). That means the same flange spacing, chainline, bearing placement, everthing. So what gives?

The key here is ease of installation. The goal of the entire 142×12 movement was to produce a system with the ease of wheel installation like a quick release, but the strength and stiffness of a thru axle. In order to accomplish this, the frame and wheel have to be self-centering which requires a recess in the frame for the hub to rest.

Most rear thru axles (150mm and including 135×12) up to this point are non self-centering, meaning you have to hold the wheel precisely in place with one hand, while you insert the axle with the other. This usually works better in theory than in practice, and definitely isn’t easier than a quick release when it comes to installing the wheel. When it comes to a self centering wheel, you can install the wheel in the frame and place it on the ground and the wheel will center up perfectly, allowing you to close the quick release. Personally, every bike I have had with a non self-centering thru axle has been an immense pain, not due to the frame, but due to the hub end caps wearing out and falling out of place every time you go to install the wheel. Of course, there will be those out there who don’t see the need for a self-centering rear wheel, but in order for mountain bikes to be sold to the masses, it is a must have.

Clearly, self-centering is the way to go, but what does that have to do with a wider, 142mm rear end? The issue here is the fact that in order for the necessary 3.5 mm of inset on the dropout for the hub to rest, 135 simply won’t work. If you were to try, you would find that either the cassette or the chain would rub on the seat stay or chainstay, due to how little clearance there is between the two. So, the only answer was to add as little to the width of the hub as possible, 3.5 mm per side, in order to attain proper clearance, hence, 142mm.

So why 142mm and not 150, or bigger?

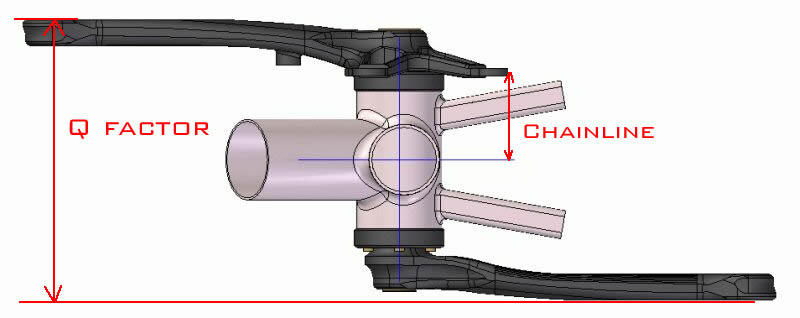

The obvious answers here are Chainline, Q-factor, and required bottom brackets. One of the benefits of retaining the same basic measurements as a 135mm spaced hub, is the fact that it has no bearing on chainline, Q-factor, or the need for a different bottom bracket. Going to a 150mm spaced rear hub would require changes to all of the above, and as it is, XC rider are already clamoring for narrower Q-factors. In order for proper chainline on a 150mm spaced rear hub, an 83mm bottom bracket would be required which would both increase Q-factor, limit the amount of compatible cranksets, and add weight.

What does all of this mean for my current bike and wheels?

Honestly, it all depends on what you have. When it comes to wheels, many manufacturers will offer wheelsets that are compatible with both standards from here on out. By simply switching endcaps, or an axle, wheels will be able to transform from 135×10 to 142×12. The only caveat comes down to the size of the bearings in the hub. The original Easton Havens for example, had bearings that were physically too small to fit a 12mm thru axle through, so no conversion option for them. Of course, this means that with hubs such as these, even if the spacing of the rear wheel hadn’t changed, there would still be a need to buy new wheels to run a 12mm thru axle. The latest version of the Havens however, were designed with larger bearings to accommodate the conversion kit. While not every wheel will have the option of converting, just because you currently have a quick release rear wheel doesn’t necessarily mean you would have to buy a new wheelset to run 142×12.

The photos above show the 142×12 conversion kit for the 2011 Easton Havens. The axle kit is incredibly easy to install and basically requires one Allen wrench and a 20mm cone wrench. There is also a 135×12 adapter available for the Havens which installs in the same manner.

On the frame side of things, many (not all) manufacturers are graciously building them so they are backward compatible with 135×10 QR wheels. Trek is one of those companies, and offers two different 142×12 axle systems: ABP Convert, and ABP FR. In the case of the 2011 Trek Fuel Ex 8 and above, the ABP Convert system comes stock with the 142×12 set up, but also includes the hardware to run a 135×10 QR. Trek’s option to accommodate this is to build two sets of ABP (Active Braking Pivot) hardware, so you can swap out the hardware in the frame and run either 142×12 or 135 QR. ABP FR on they other hand, gives rides the ability to choose between 142×12 and 135×12 on bikes such as the Trek Scratch.

Other bike makers, such as Yeti, instead opt for a complete replaceable drop out system which gives even more rear wheel freedom, as it even makes set ups such as sliding single-speed drop outs possible. As stated, not every manufacturer is building in the backwards compatibility, but for those who are I feel it is commendable, and illustrates said companies ability to empathize with consumers in regards to changing standards.

Pros of 142×12:

- Larger captured axle means stiffer, stronger rear end and less deflection of rear hub

- Easier wheel installation than 135×12 or 135×10 QR

- Due to its design, the thru axle satisfies CSPC wheel retention requirements in an extremely simple and repeatable manner

- Design guarantees the same wheel alignment each time the wheel is removed and installed

- Some current wheels and frames are compatible with adapter kits

- Retains the same chainline as 135 QR wheels, which means no bearing on Q-Factor (going to a wider hub, say 150, would require the use of a wider BB, therefore increasing Q-factor)

Cons of 142×12:

- Obviously it is a new standard which may, or may not require new wheels

- Most 2010 and prior frames aren’t compatible

- Currently, most 142×12 bikes are not rear-wheel trainer compatible (not so much an issue on full suspension trail bikes, but more so on future XC hardtails)

- New bearing size for freehubs has the potential to negatively affect bearing longevity

Clearly, with the amount of brands on board that are slowly introducing 142×12 bikes and parts over the next few years, it seems the “standard” isn’t going anywhere. What’s important to remember though, is that just because more and more bikes will be shipping with the larger axle, that doesn’t mean the end of the 135mm quick release as we know it. No one is forcing the upgrade on anyone, but for those who want it, it’s there. The idea of being forced to buy new parts is a somewhat moot point due to the fact that if you are buying a bike with 142×12 it will have everything you need already. Even if you already have a set of high end 135×10 QR wheels, there is a good chance you will still be able to use them with the conversion kits offered by many manufacturers. Also, those interested in upgrading their wheels now, who don’t have a 142×12 frame yet (but my in the future) will have the option to purchase wheels that are compatible with both standards. Nearly every possible concession has been made by manufacturers to ensure the most painless transition for consumers as possible.

Does everyone need the benefits of the larger axle, and simplified installation? Of course not, but there are those who will benefit more than others, and in the end – if it makes mountain biking safer or easier, we all win.

So what are your thoughts? Have you ridden a bike with 142×12? Plans to buy one in the future? Tell us below!