TIME Bicycles unveil the all-new ADHX all-road & fast gravel bike using their unique woven carbon construction reinforced with industry-first Bio-Based Dyneema fibers made from wood manufacturing waste. Calling it their “debut gravel bike”, the new Alpe d’Huez X (ADHX) leans more in an all-road direction with somewhat narrow-for-modern-gravel tire clearances, but it packs a lot of exciting new manufacturing tech into a premium carbon bike made entirely in the EU…

TIME ADHX bio-Dyneema carbon all-road gravel bike

The all-road leaning carbon Time ADHX is a fast gravel bike promising a ‘perfect blend’ of lightweight, power-transfer & handling stiffness, rider comfort, and all-terrain durability – all tuned for limitless mixed-surface riding.

It gets a unique high-performance blend of carbon to come in just over 1 kg with gravel-ready toughness and room for 40mm tires.

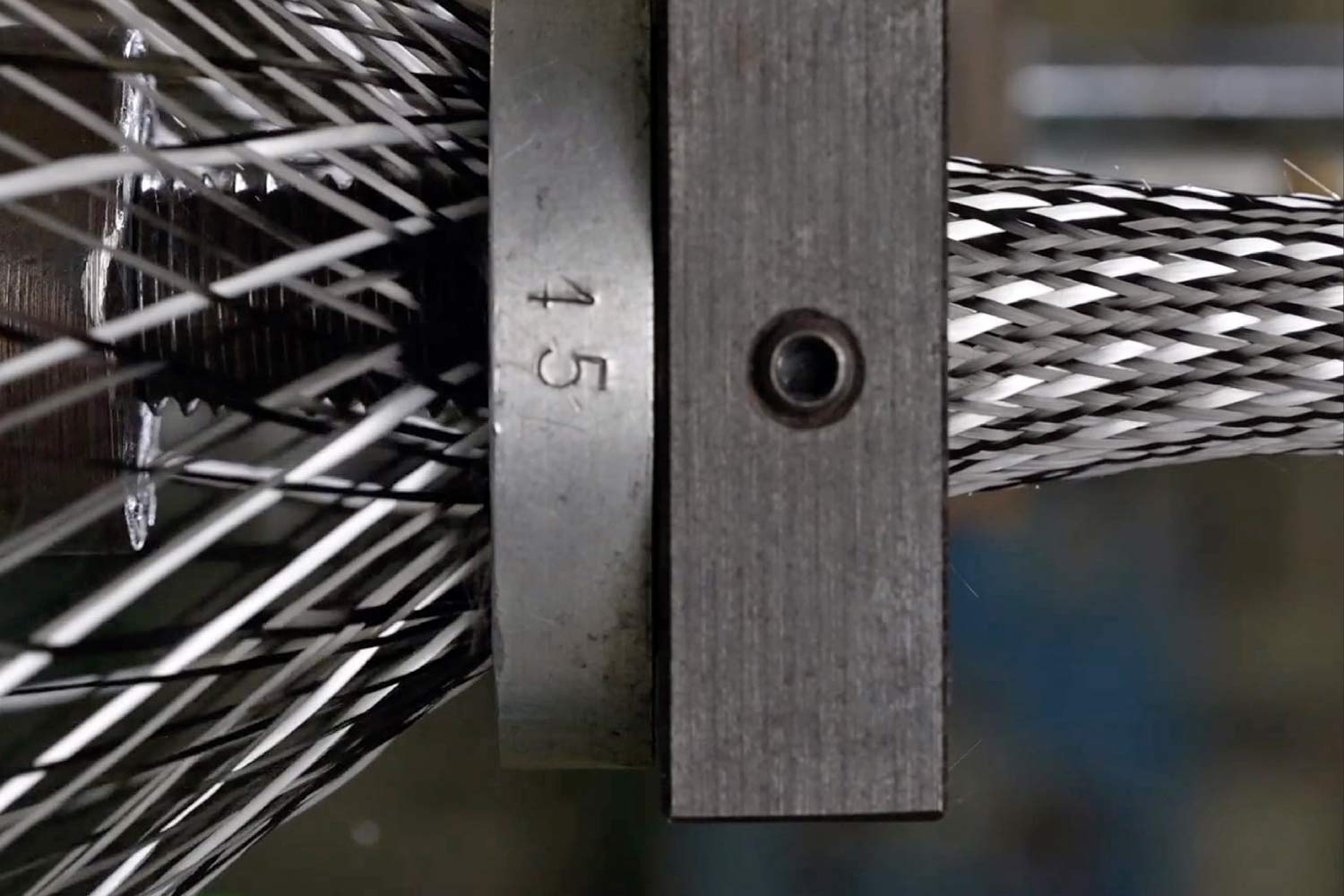

Braided Carbon Structure & Resin Transfer Molding

Time gave us an in-depth look at the unique way they were going to weave together carbon to make their bikes this past winter. And the new ADHX gravel bike is their first model to take this Braided Carbon Structure (BCS) system off-road.

By radially braiding dry fibers Time has unmatched control of material placement with the tubes of their frames, while also allowing them to introduce unique reinforcement like this new Bio-Based Dyneema, Vectran, more conventional hi-mod carbons, or even Kevlar to address specific loads on a bike.

Time only adds the resin under pressure into the final complete mold (RTM) , after individual tubes are woven over mandrels then assembled together dry into a complete bike. This allows much more precise fiber placement, more layup flexibility, more workable molding time since they are using pre-preg, and ultimately a lighter & more refined resin composition.

This is in many ways similar to how 3T makes the Torno cranks & the new Exploro Italia at their HQ in Italy.

Bio-based Dyneema

We mostly know Dyneema in cycling from fiber spokes, bikepacking bags, ultralight textiles in shoes or even crash-resistant bib shorts. But the ultra-high molecular weight polyethylene (UHMWPE) fiber that claims to be 15x stronger than steel can be woven into textiles for all manner of reinforcements.

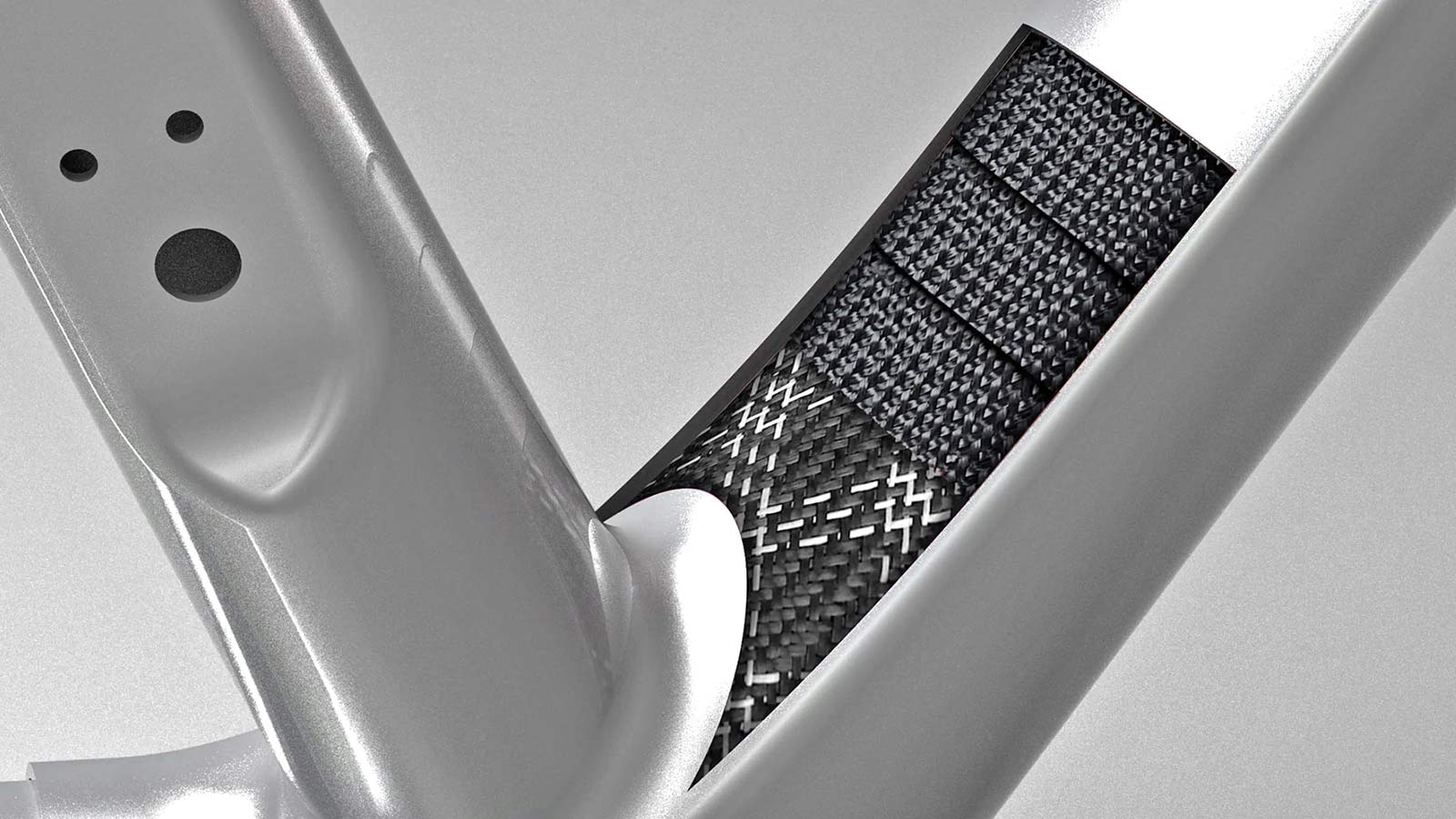

Time braids it with carbon to increase the safety of their new ADHX all-road & gravel frame in a crash. Engineered to only incrementally increase the strength of the frame in an impact, the Dyneema fibers remain structurally sound for a much longer period after the carbon fibers fail, keeping the bike from failing in a catastrophic way. Effectively, the Dyneema reinforcement allows the carbon bike to bend more like a steel bike vs. the traditionally more brittle failure mode of conventional carbon bikes.

You won’t actually see the Dyneema in the ADHX, though. Time only weaves it into the inner workings of the ‘BCS sock’ at the junctions of the headtube, downtube & toptubes. There, a 20-25% Dyneema composition helps resist high internal forces in the event of a crash, keeping the bike together and keeping the rider safer.

The bio-based version of Dyneema apparently retains all of the performance characteristics of the original petrochemical UHMWPE, but with a 90% lower carbon footprint than generic high-modulus polyethylene (HMPE) according to its manufacturer. The fibers are synthesized from wood waste from the timber & pulp industry, combined with some conventional fossil fuel-based material to create the ethylene.

It’s not totally fossil-free, but 1 ton of bio-Dyneema has a 5 ton CO2 reduction compared to conventional Dyneema (or 29 tons less than generic HMPE).

Tech details

Time’s new BCS woven carbon ADHX frame – made in Gajary, Slovakia – has a claimed weight 1025g (small, unpainted) with forged carbon dropouts. Officially Time says the all-road / gravel bike has 700c x 38c tire clearance, for a real 40mm measured tire width. Of course, depending on rim width, some 40mm gravel tires might not fit.

The ADHX features fully-internal cable routing through the Deda DCR headset system, which can also work with conventional bars & stems and a cable port in the upper headset cap.

The frame is 1x & 2x compatible with mechanical & electronic drivetrains, and includes a sleek cover over the mounts for the removable front derailleur tab. It features 12mm thru-axles, flat mount disc brakes, BB386 bottom bracket, a replaceable derailleur hanger, and a tidy external alloy clamp for the 27.2mm round seatpost.

Mounting points include a standard pair of cages inside the main triangle, plus a set of direct mounts for a toptube bag.

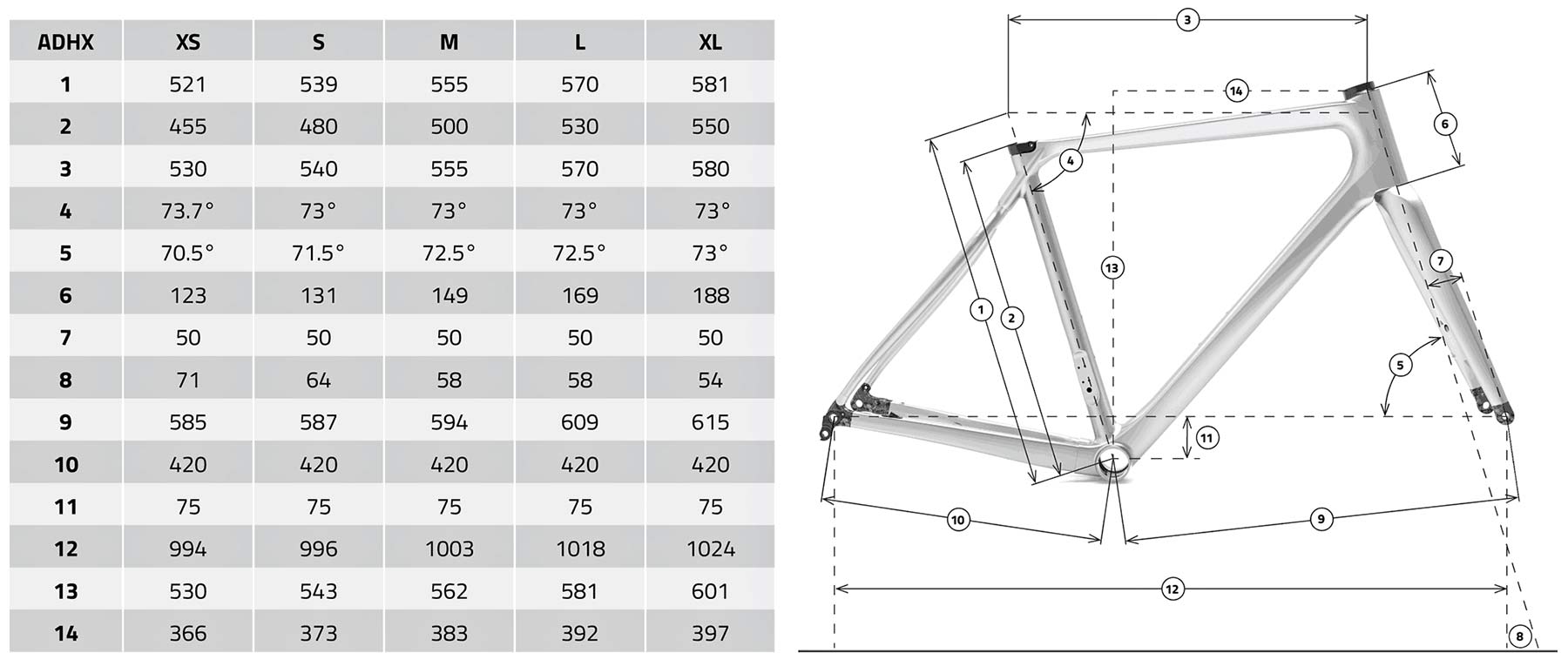

All-road Geometry

The ADHX’s geometry is more endurance-focused than their similar-looking Alpe d’Huez 21 light road bikes. The all-road feel is meant to be a bit more relaxed & stable with longer wheelbases and 420mm chainstays. But frame Stack & Reach are essentially the same as on the road, with only a slightly slacker (0.5-1°) head angle across the five size range.

TIME ADHX – Pricing, options & availability

Time’s new ADHX gravel all-road bike is available now only as a frameset, but you can pick how you want it to look.

For 3300€ you can pick up a ready-to-paint, primer primed frameset.

Or for 3500€ the EU-made gravel bike comes in four glossy transparent colors that reveal the woven carbon underneath – Amber brown, Cobalt blue, Forest green, or Carbon black.

Then it’s up to you how you spec out your dream bio-Dyneema gravel bike build.