Welcome to Tire Tech, Bikerumor’s mostly-weekly series on bicycle tires. Like our Suspension Tech and AASQ series, we take your questions about tires, whether it’s road, cyclocross, fat, plus, gravel, or mountain bike, and get answers from the brands and people behind them.

When selecting tires, mountain bikers often fixate on rubber compounds, tread patterns and weights, sometimes overlooking the construction of the casing and the additional layers applied to it. Not to dismiss the external features, but the hidden elements in a tire are equally important.

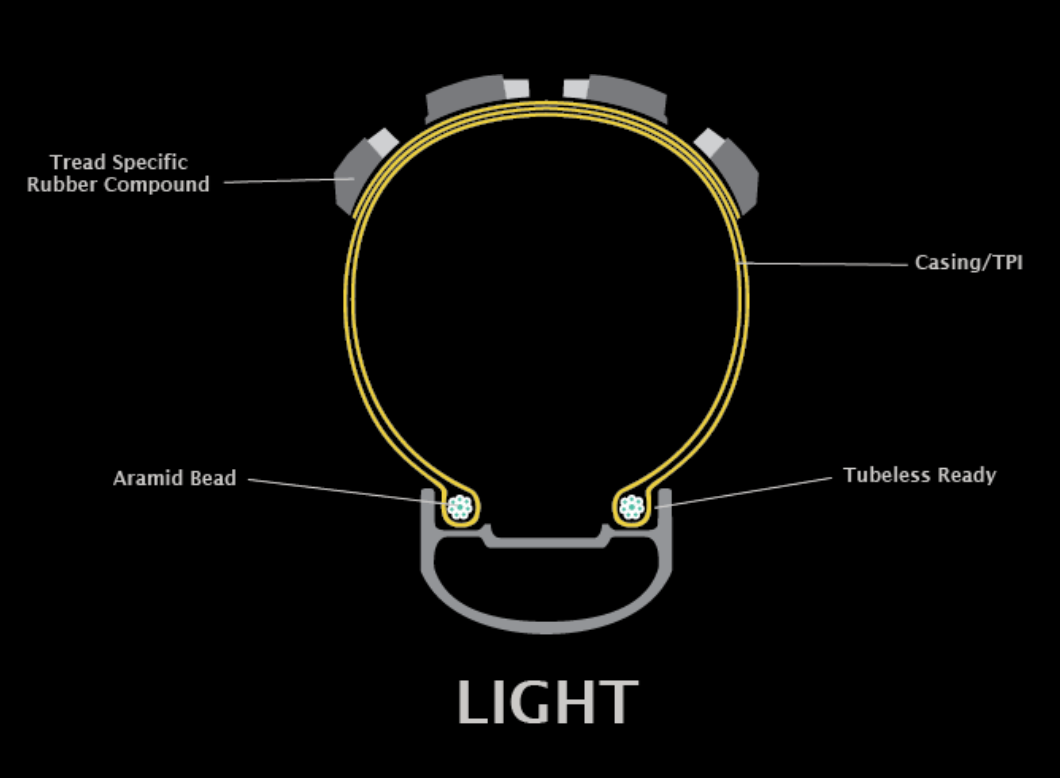

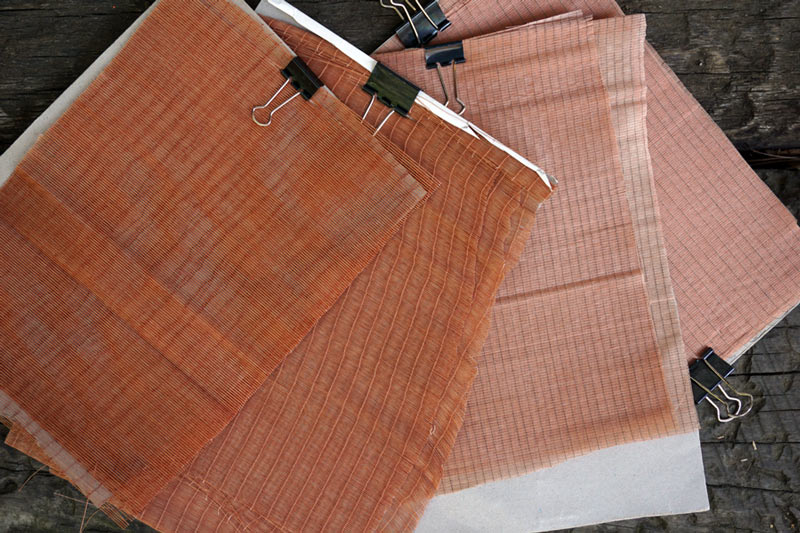

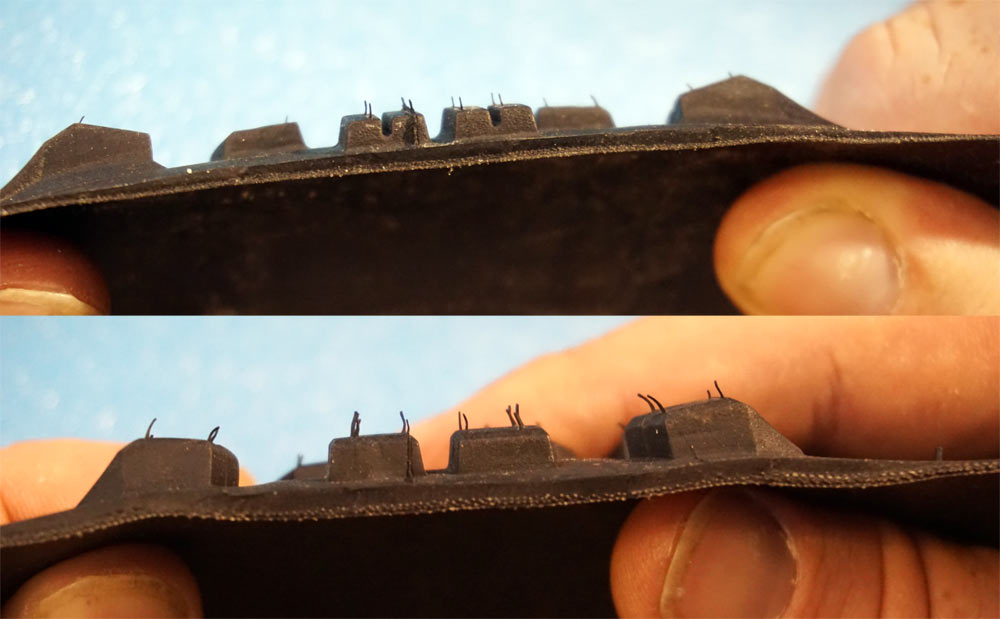

Although the bike tire market is rife with buzzwords and proprietary sounding technologies, basic tire construction is largely the same across the board. Casings are made of parallel nylon fibers coated with rubber to create the fabric’s desired thickness. The fibers are aligned at a 45º angle to the tire bead, often in multiple layers in alternating directions. Atop that foundation additional materials may be used to increase stiffness and defend against punctures and cuts. All of this before any tread is applied.

By carefully selecting materials and how they’re layered, product developers can create a tire with specific attributes. They can engineer tires with optimal rolling efficiency, lighter weight, beefed up durability, or built to charge hard on challenging surfaces. For this post, we asked Tim Krueger of Terrene Tires to walk us through the various layers and what they do.

Thread Counts & Plies

Most tire buyers are familiar with the concept of thread count, but may not understand how it plays into durability and overall performance. Thread count refers to the number of individual fibers per inch in the casing’s base fabric. Typically grouped into two categories, low-count tires generally have 60 threads-per-inch whereas high-count tires have somewhere around 120. Some tires go as high as 170tpi or more, but those are usually reserved for professional racers on race day only.

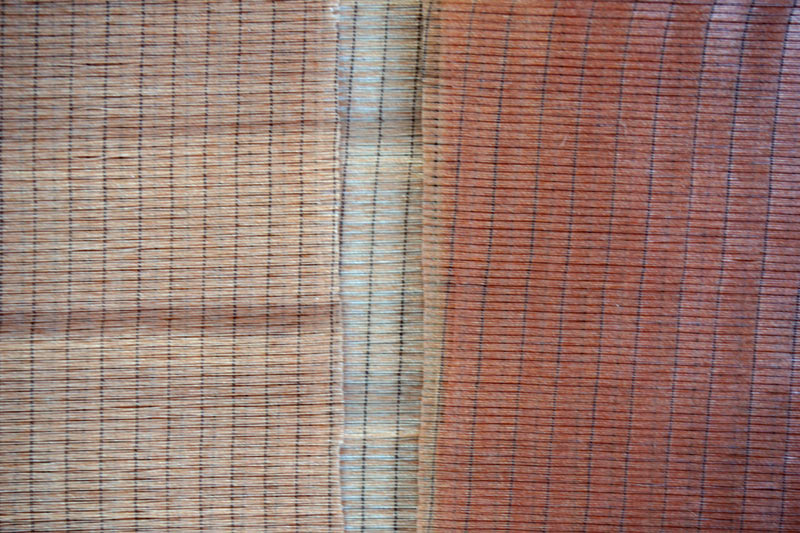

Lower thread counts use thicker threads with larger gaps between them. Higher thread counts pack more fibers per inch because those fibers are thinner, and more tightly packed.

As such, Krueger says higher thread counts require less rubber to coat the fine and tightly spaced threads. This yields a fabric with thinner rubber laminates and a lighter, more supple casing that’s able to flex more easily. The creates a tire that conforms to the trail better, and that compliance improves rolling efficiency, comfort, grip, and overall ride quality.

A 60tpi tire requires thicker applications of rubber resulting in more weight and a less pliable material. But there are advantages to low-count casings. The fibers in a 60tpi tire are more coarse and inherently more cut-resistant. Although not always the case, lower count tires, by virtue of their added rubber, are stiffer and a better choice for use in demanding terrain.

The Casing’s Contribution to Ride Quality

With the thread count chosen, tire designers then determine how many layers of casing material are required to achieve the desired results. A single-ply tire will usually offer the lowest rolling resistance at the expense of durability. The more plies that are added the more the cut and puncture resistance increases—at the sacrifice of rolling efficiency. The extra plies also stiffen the carcass. It gets more complex than just the layering of fabric. Although they’re technically not casing material, most tires include extra laminated layers to boost durability and stiffness as desired.

Krueger is quick to point out how thread count alone does not determine a tire’s performance characteristics. The additional layers and rubber laminates atop the casing impart as much if not more influence. This is a concept regularly measured and discussed in the findings of Jarno Bierman at bicyclerollingresistance.com.

If you cap a high-quality 120tpi casing with thick layers of rubber and stiff armored laminates, they will negate the advantages of the fabric. As such, it is possible to produce a 60tpi tire with better ride quality than one with twice the threads. For this reason, Krueger says they don’t add reinforcements to their 120tpi tires. Protective layers require extra rubber to incorporate into the tire and the added weight negates the benefits of the expensive high-count material.

As Krueger puts it, “This is the magic mix that sets manufacturers apart. Some use one-ply casings with protection layers. Others use two-ply with protection layers. At Terrene, we actually do all of those on different tires. We custom tune each tire for the type of riding it is intended for by using all methods of reinforcements.”

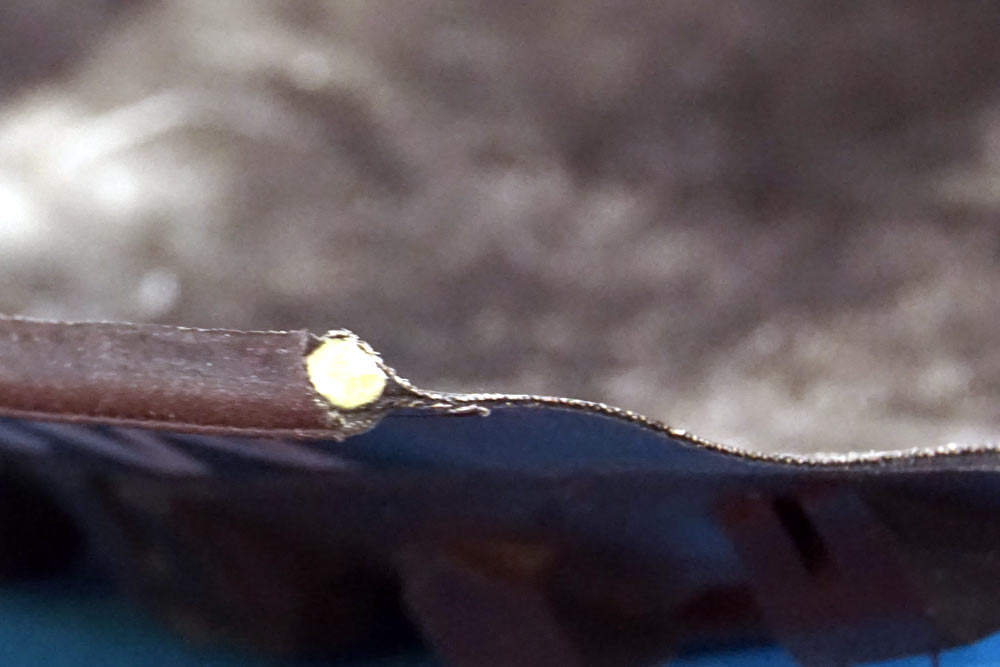

He went on to explain how the protective elements within tires are changing with the times. With advancements in suspension, wheel designs, and perhaps just due to the evolving skills of today’s riders, tires are being pushed to new limits. Sidewalls are now as likely, if not more so, to see damage as the tread surface. But they can also be used to support really aggressive riding while still allowing lower tire pressure.

Krueger offers this advice regarding the nuances of tire selection: Some people advise putting a more durable tire, often a reinforced 60tpi tire, on the back wheel with a lighter 120tpi skin up front. However, the front wheel can take as much abuse as the rear. Knowing how you ride and honestly assessing the demands you place on your tires will guide you to the appropriate product.

In a future installment of Tire Tech we’ll take a much closer look at tire reinforcements, how they’re integrated into the casings and why.

This Episode is presented by Terrene Tires. At Terrene, we put riding at the center of the experience. We understand what matters most—be it an afternoon on your favorite stretch of singletrack, a long day on an unending dirt road, or a worldwide tour. We took what we have learned through decades in the bicycle industry to bring you tires that are designed to ride how you do. From the very beginning of the process until the tread hits the dirt, we bring together our experience in product development and a passion for riding to create tires that are ready to ride for people that live to.

Pumped on this? Got a question you want answered? Email us. Want your brand or product featured? We can do that, too.