Token wants to eliminate all of the downsides of Press Fit bottom brackets with their new Thread Fit setup. They aren’t the first company to come up with the idea of threading a bottom bracket back into your modern Press Fit bike, but with a modular system, a couple of bearing options, and a wide range of frame & crank compatibility, they are trying to make it easier on both bike shops and individual cyclists looking to get rid of creaking and bearing drag (as well as brute force to install BBs.) They’ve also got a trick new thru-axle concept, all after the break…

Thread Fit bottom brackets

What they’ve done is built is a modular bottom bracket with two aluminum shells that thread together inside of your frame. A variety of composite adapters slide over the shell and interface securely with your frame’s bearing seats. The result is a securely threaded-together shell that ensures its bearings are properly aligned on both sides and clamped down tight inside your frame, so there are no creaks and your cranks can spin smoothly with longer bearing life.

The Thread Fit bottom brackets are available both with Token’s standard premium stainless bearings for around $50 for a specific bike setup or for about $120 with their TBT ceramic ball bearings.

The Thread Fit bottom brackets are being made available in individual complete setups specific to a bike and crankset combination or in kits that make it easier to fit a wide range of different bikes and cranks, so for example bike shops can always have on hand what they need and restock as they install them. Each of the kits comes with a pair of composite BB wrenches that allows you to safely tighten down the alloy cups without damaging either the bottom bracket or frame, and they also are available separately.

The Shimano-specific Thread Fit 24 kit retails for about $60 and includes the universal Thread Fit bottom bracket with standard bearings, plus adapters to fit 5 crank/frame combos: Shimano 24mm axle cranks in BB86, BB90, BB92 BB30 & PF30 frames.

The Thread Fit 37 kit brings the price up to about $90 with a broader fit range and includes the standard bearing universal Thread Fit bottom bracket and the adapters to fit 7 crank/frame combos: Shimano 24mm axle, SRAM GXP 22/24mm axle, BB30 & BB386 cranksets in PF30 & BB386 frames.

Token also individual solutions for Cannondale BB30A frames with Shimano cranks, GXP adapters for all frames, and Cervelo BBRight bikes to be used with Shimano, GXP, or BB386 cranks.

Press Fit

If you want to stick with a standard press-in bottom bracket setup, but want to go with either Token’s standard steel or affordable composite ceramic bearings, they’ve probably got you covered too. Token aims to offer replacement and upgrade bearings to fit just about any frame, no matter what solution you want to go for.

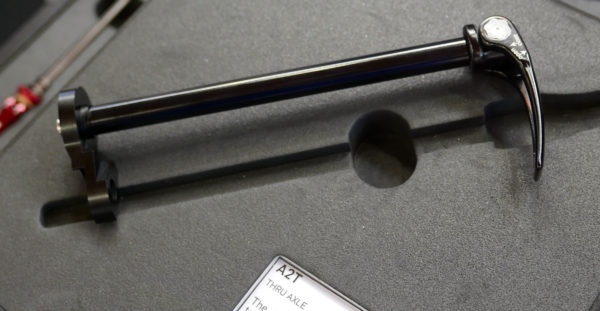

A2T thru-axle

It isn’t just bearings (or wheels) that Token is developing. They also showed us a neat thru-axle design with the idea of a secure interface but with faster wheel removal. Basically the A2T (Axle 2 Turn) is just a very coarse threaded axle that would thread into a captured nut in a frame or fork.

Just two rotations of the QR lever allows it to be completely removed, and the position of the internal cam lever can be adjusted with the nut on the other end. Token is working with frame makers to get it built into you next road or mountain bike for a more mechanically simple alternative to some of the other quick thru-axle concepts floating around.