SRAM has published a patent detailing elastomer-damped shock end mounts, said to reduce high frequency, low amplitude vibrations transferred from the trail to the rider. The end mounts can be utilized on either end of a shock, or both ends simultaneously, to damp the low-level trail chatter that a conventional shock is unable to.

Sound familiar? Indeed, this invention seems to perform the very same function performed by the ButterCups you’ll find inside RockShox Ultimate level Zeb, Lyrik and Pike suspension forks. Actually, the inventor named on this particular patent (US 20230271672 A1) is Timothy Lynch. He is the RockShox engineer whose idea it was to implement these elastomeric pucks on the brand’s suspension forks after he discovered first hand the negative effects of high-frequency, low amplitude vibrations whilst using a chainsaw.

The technology is in fact not new. Corratec implemented something similar with a RockShox shock back in 2014 and 2015. Indeed, they took the 10Hz damper to production on a 100mm travel XC bike and a 175mm travel enduro bike, in a bid to provide frictionless small bump absorption.

Regardless, this very recently published patent from SRAM (filed Feb 25th, 2022) indicates that SRAM may be looking to develop the technology further. Here’s more.

Vibration-Damping Shock End Mounts from SRAM

Before we dive into the details, it’s pertinent to discuss why such technology is required, and what benefit it might have for us mountain bikers. After all, aren’t modern shocks good enough already? Sure, the vast majority of them do a fantastic job of compressing and rebounding to absorb medium to large bumps, allowing our tires to maintain safe, consistent contact with the ground. Modern dampers are configured to control those compression and rebound events to deliver a smooth, controlled ride feel for the vast majority of riders.

A Flaw of the Modern Shock

What they are not so good at doing is absorbing the high-frequency, low amplitude vibrations that arise from trucking over the much smaller, consecutive bumps that litter any trail or gravel road. That’s because, in order for any shock, air or coil, to compress or rebound, there is a threshold force that must be overcome. Seals around the air spring or piston have a certain amount of stiction associated with them. To get them sliding freely, the breakaway force must be overcome.

These high-frequency, low amplitude vibrations don’t offer up enough force to overcome this threshold, and so they aren’t absorbed by the shock. Instead, they are transferred through the frame and into the rider’s hands (or feet). That causes fatigue. We’re all quite familiar with arm pump, right?

What’s more, these vibrations have been shown to illicit a significant response from a rider’s immune system. This was shown by Dr Lewis Kirkwood, an Edinburgh Napier University student who dedicated his PhD to the topic. Clearly, any technology that can prevent these vibrations from reaching the rider should be considered. So long as it doesn’t impinge upon the overall riding experience, that is.

A Possible Solution

Evidentially, SRAM has a good appreciation of this, having implemented the vibration-damping ButterCups on high-end RockShox suspension forks. The above shows how two elastomeric pucks are compressed and expanded, either side of a metal plate, to absorb vibrations that are sent up through the front wheel into the fork’s lower legs. RockShox say their ButterCups add about 4mm of vertical compliance to your suspension and an average of 20% reduction in trail chatter from reaching your hands.

Now, it seems they are considering something similar for rear shocks, in a bid to reduce trail chatter reaching your feet (and subsequently, quads).

How do the SRAM Shock End-Mounts Damp Vibrations?

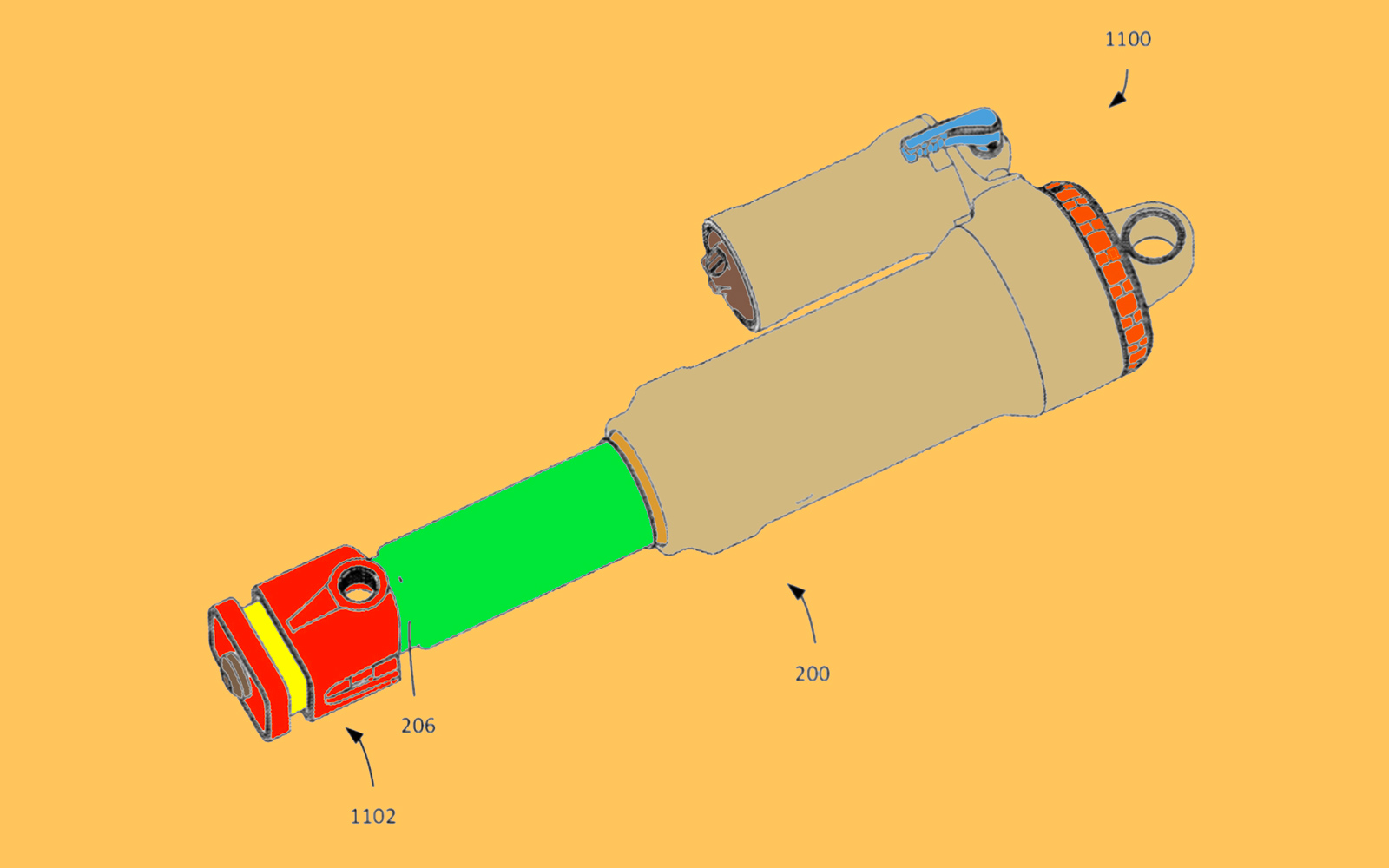

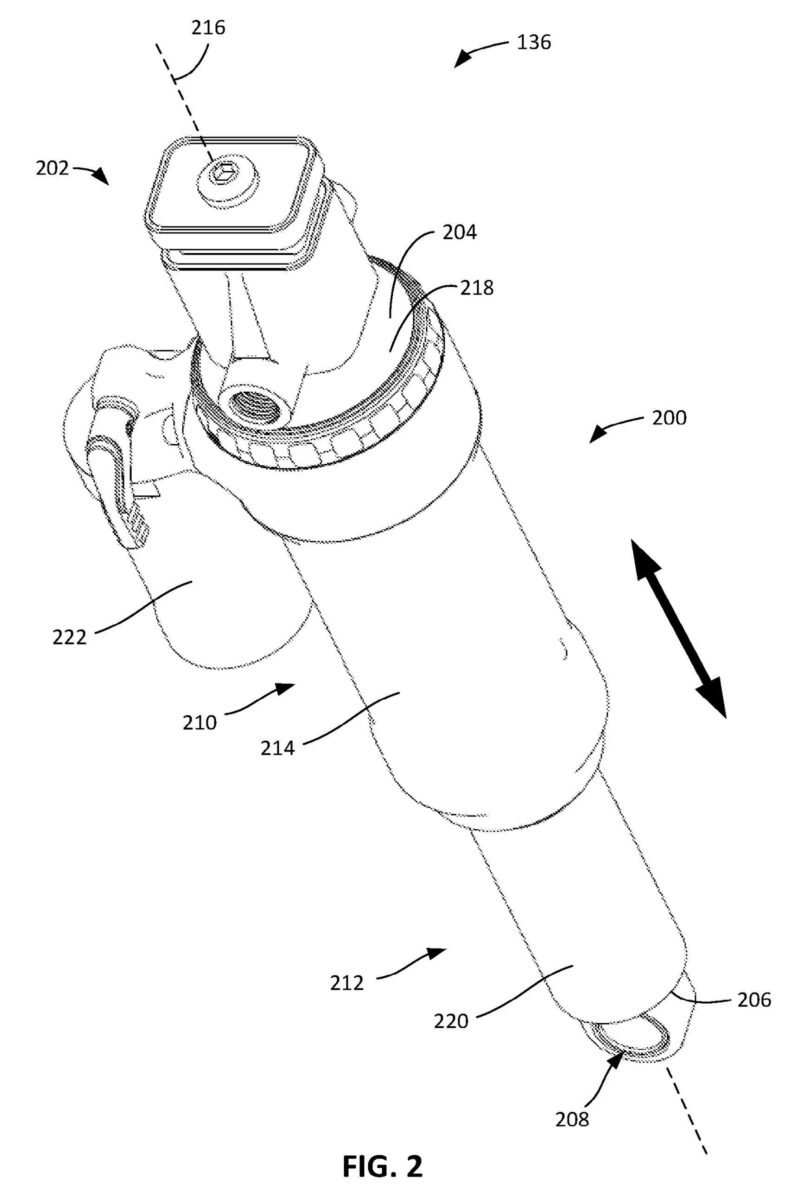

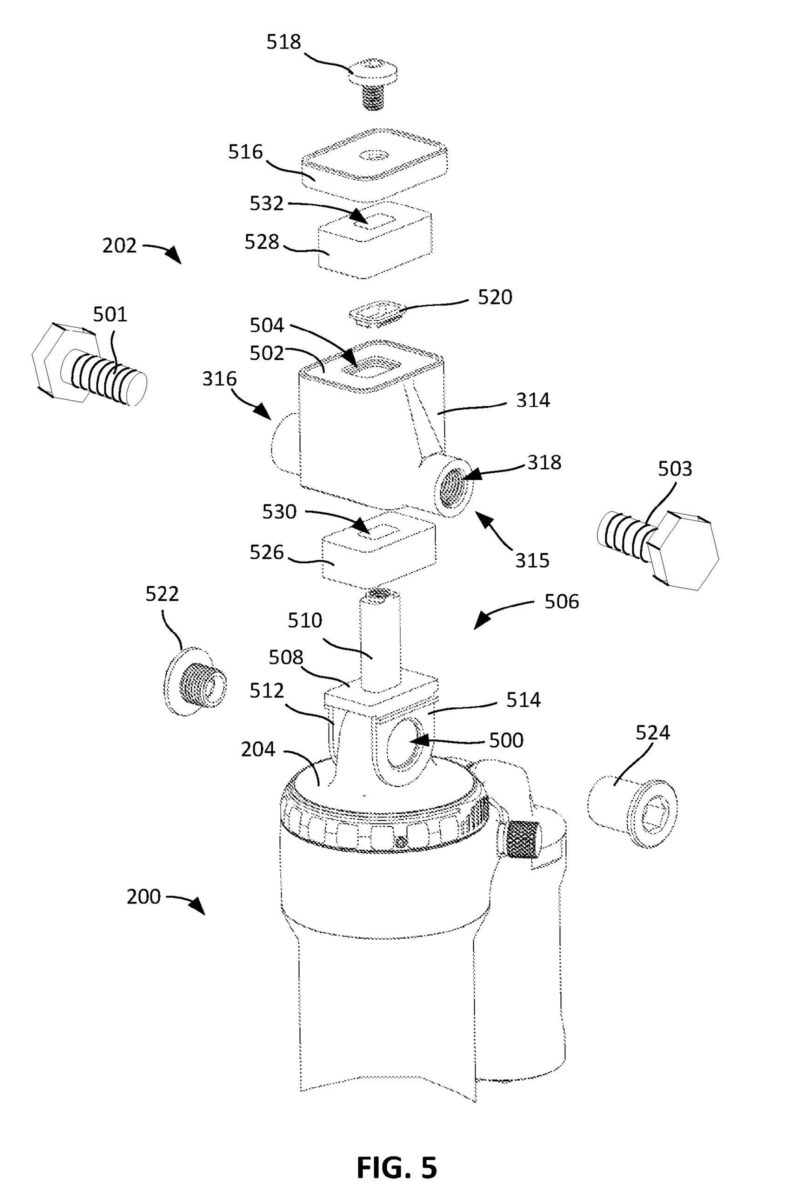

Essentially, the shock end mounts described by SRAM are an intermediary between the frame (or rocker) and the shock. The shock end mount bolts directly to the shock via its eyelet or trunnion mount, and it bolts directly to the frame or rocker. But, these are two distinct mounts.

The shock end mounts make use of this decoupling of the shock from its frame or rocker mounting location, allowing relative movement between the two. Stuffed into the space where this relative movement occurs are two elastomers that, through their compression and expansion, are able to absorb vibrations – just as shown for the ButterCups, above. The shock end mount thereby becomes a spring itself, working in series with the main spring of the rear shock.

What’s key here is that the force required to compress the elastomers is well below the breakaway force – the force required to push the shock into compression (or rebound). This is how SRAM propose to reduce the volume of undesirable high frequency, low amplitude vibrations that reach the rider.

The patent reads, “…long and slow inputs are partially absorbed by the shock end mount and transmitted to the shock absorber, whereas fast and short inputs are absorbed just in the shock end mount. As a result, the shock end mount reduces vibrations felt by the rider (e.g., at the handlebars and/or the seat”.

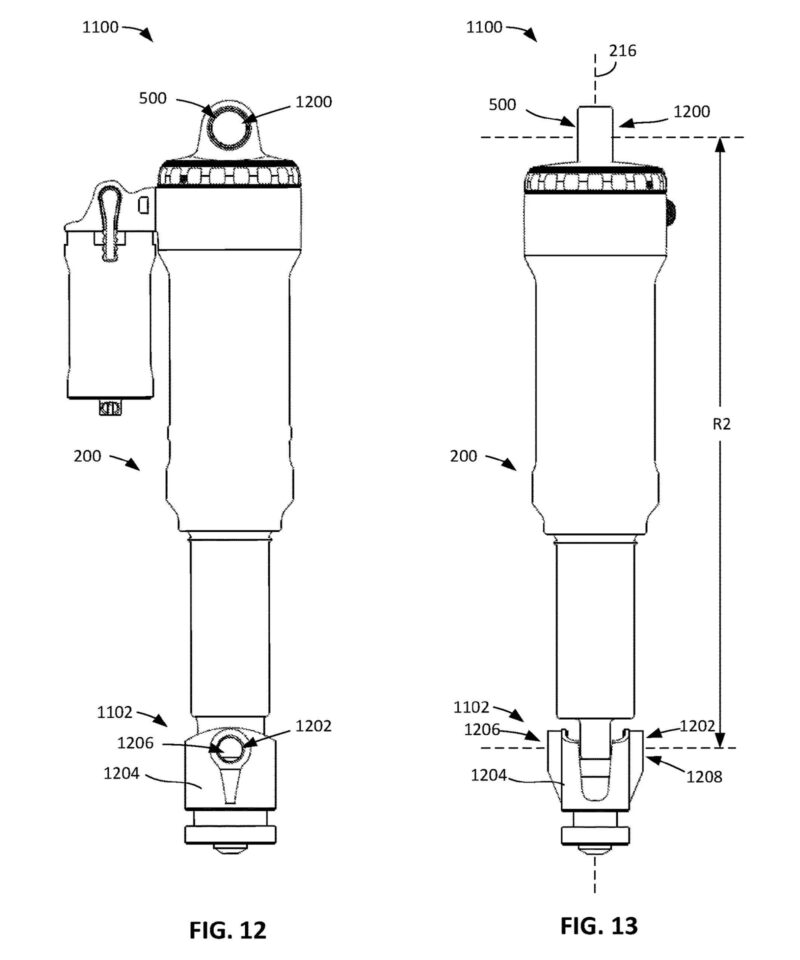

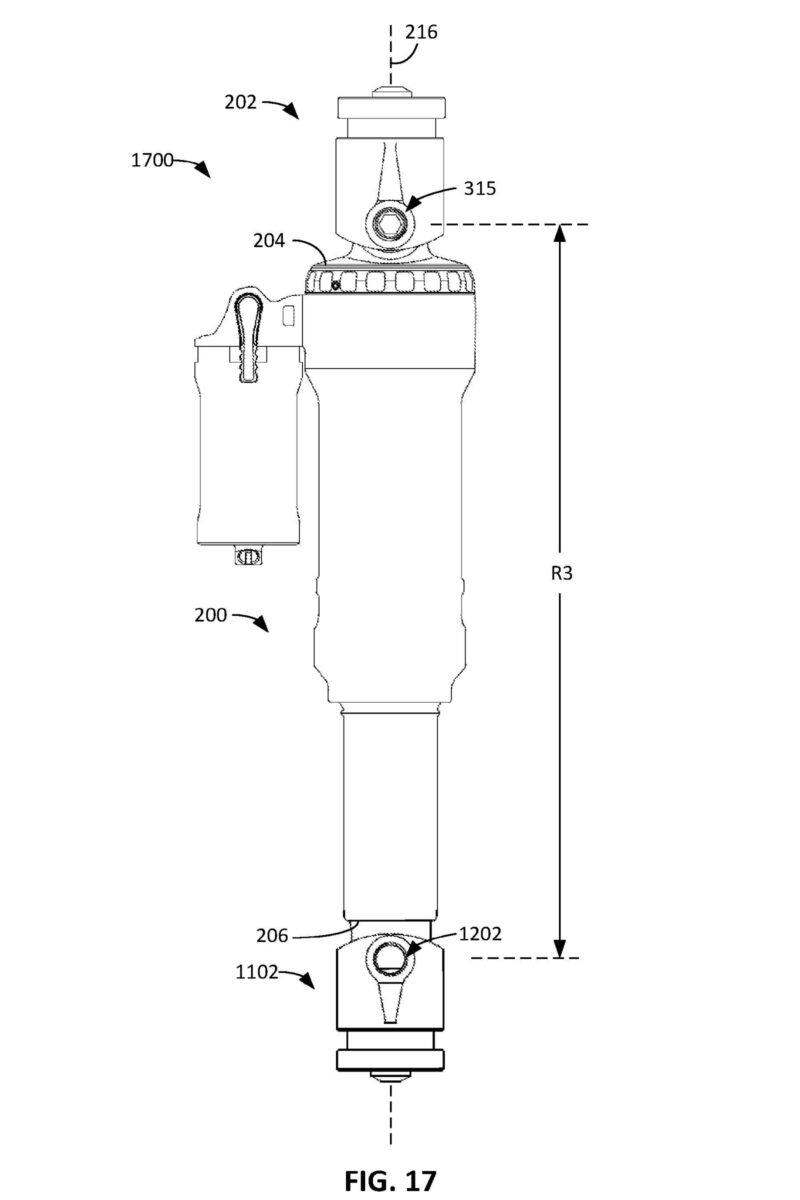

The document shows a shock running a single shock end mount (Fig. 12 & 13), and another shock running two of them – one on each end (Fig. 17). For the latter example, one can imagine how the shock will essentially oscillate over a very short distance – just a couple of millimeters, perhaps – as a rider rolls along a gravel road, for example.

This oscillation is described as a “fluttering” by the named inventor, Timothy Lynch.

How will the SRAM Shock End Mounts affect frame design?

Sure, the shock end mounts described in the SRAM patent do take up considerable space. How much space is yet to be seen, but the patent says they can be smaller than 20mm, 30mm, or 40mm in length. It’s likely the size will be heavily dependent on the application, be it on a downhill, enduro, trail, XC or even gravel bike.

Importantly, the arrangement of the shock end mounts is such that the overall length of the shock should remain unaffected. The elastomeric damping stack sits outwith the shock body itself, so the eye-to-eye length doesn’t necessarily need to be shorter. Sure, some linkage designs will be much more amenable to use of the shock end mounts than others. It is however, likely that frame manufacturers will have to rework the dimensions of their frame shock mount tabs and rockers to accomodate the additional hardware.

If the shock dimensions are unaffected by the addition of the shock end mounts, then the bike’s leverage curve and suspension kinematic should be largely unaffected, too. If implemented as SRAM foresee, these special mounts stand to improve the small bump sensitivity of any suspension platform.

Throughout the patent, only air shocks are shown with the shock end mounts installed. However, SRAM do suggest they could be used on coil shocks, too. However, air shocks exhibit far more stiction than coil shocks due to the presence of more seals. For that reason, it seems it is the air shock that stands to benefit most from this invention.

Will the SRAM Shock End Mounts go to Production?

It’s impossible to know, of course. Brands don’t always execute on the inventions they patent. However, we’d bet that some form of this technology will end up on future iterations of the RockShox Deluxe, Super Deluxe, or Vivid shocks. Perhaps even the SIDLuxe shocks, weight permitting. Given the existence of ButterCup technology inside high-end RockShox forks, it seems this avenue of marginal gains is an avenue that SRAM/RockShox are happy to mince down.

We reached out to SRAM for comment, but it’s a “no comment” for now.