Ex-aerospace engineer, Joe McEwan, is the man behind British mountain bike brand, Starling Cycles. While Starling do get some of their bikes, and parts of thereof manufactured in the far east, Joe himself and Clandestine founder, Pi Manson, still hand-build a full range of mountain bikes out of their workshop in Bristol. Joe was an expert in carbon fiber stress research in his previous life but has settled on steel as his material of choice for bicycle frames. We had a brew with Joe at the workshop to find out more about his bicycle building journey, and the story of Starling Cycles.

British-designed and built Starling Cycles

“I had a big shed, and I thought, I can build bikes in there”, said Joe McEwan. I mean, isn’t that what everyone thinks when they look at their garden shed? Joe took training from famous bicycle frame builder of the 90s, Dave Yates. On the course Joe built his first hardtail mountain bike, learning all the basics of frame building in the process; how to braze, how to cut tubes, etc. That first bike had a really steep head angle (71°!) – as soon as he got back, Joe knew he had to slacken that off. Into the shed it went, onto a wooden jig, and it seems Joe hasn’t looked back since.

The first full suspension MTB building project Joe embarked on was a front triangle built around an original Cannondale Prophet swingarm. Next was a single-speed full sus, then onto the first enduro bike that he actually raced an Enduro World Series round on. Joe sold his first batch of bikes as prototypes, a 27.5″ and a 29er full suss MTB that did rather well in a Dirt Magazine test against some top end carbon bikes – the Starling was consistently quicker. All of this was actually only 3 years ago; only 2 years ago did Joe go full time, and Starling Cycles has been housed in the Bristol workshop for the last 18 months.

Starling Bikes

Starling Cycles now offer a full range of hand-built steel frame mountain bikes; the single-speed full suspension Beady Little Eye (best name ever, no?), the Swoop 27.5″ full suspension trail bike, the Murmur 29″ Enduro bike (rave reviews, I tell you), the Migration round-towner bike, and a Jack-drive inspired single-speed downhill MTB, the Sturn. That’s quite the portfolio after just 3 years of hand-building frames. Starling also recently showed a new EffiGEAR gearbox mountain bike at Bespoked, named the Spur, after the talon on the back of a starling’s leg.

The Beady Little Eye and The Big Beady Eye

The Beady Little Eye is Starling’s 27.5″ full suspension single speed mountain bike. Built from a combination of Reynolds 853/631 and Columbus Life and Zona tubing, the Beady Little Eye offers 110mm of rear wheel travel pivoting about the bottom bracket.

The Big Beady Eye is a natural evolution of the Beady Little Eye, offering almost the same configuration but with slightly less travel (90mm), a lower BB drop (50mm), and slightly longer stays (440mm).

Starling Swoop 27.5″ Trail/Enduro Bike

The Swoop is definitely one of Starling’s more popular, less eccentric bikes, and fits a lot more with Starling’s ‘Fast, Simple, Silent’ philosophy. It is a single pivot full suspension bike offering 155mm of rear wheel travel. Made from a combination of Reynolds 853/631 and Columbus Life and Zona tubing, the frame provides clearance for 2.5″ tyres. The tubes are combined with laser cut and machined steel parts, resulting in a frames where Joe says simplicity and ride character are the driving design parameters.

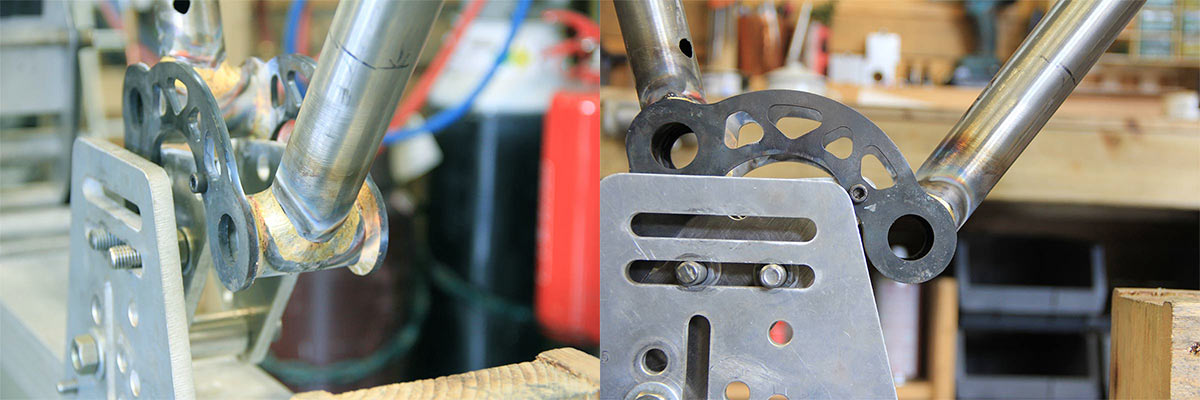

The Swoop chainstays of the swing arms are ovalised with a dimple on the inside, purely to provide an extra 3-4mm of tyre clearance. All Starling frames that are made in the Bristol workshop are fillet brazed while the frames and swingarms made in Taiwan are TIG-welded.

Starling Murmur 29″ Enduro Bike

Built with Reynolds 853 steel tubing, the Murmur is Starling’s 29er Enduro bike. This is the one you’ll go fast on. A metric shock services 140mm of rear wheel travel. The Murmur frame has tyre clearance up to 2.5″ and the brake mounts are positioned to allow rotor sizes up to 200mm. The new ‘Factory’ frame is designed in the UK and hand built in Taiwan by ORA. Joe made the decision after visiting the factory and seeing first-hand the high quality of manufacturing, work ethics and working conditions. A custom version of the Murmur is also available; these have been hand-built in the Bristol workshop and the ~£200 price difference reflects that.

Starling Sturn Downhill Bike

The Starling Sturn downhill bike came out of Joe’s desire to build a single speed downhill bike that wouldn’t suffer from any chain growth as the suspension moves. It features left hand drive BMX cranks that drive a cog with an axle that runs through to the other side of the frame to drive a second cog which drives the single rear cog rotation. As the main pivot sits around the drive, as the suspension moves through its travel, there’ll be no change in the length of the chain, resulting in no pedal kick back whatsoever.

Starling Spur Gearbox Bike

This 170mm travel 29er is a hell of a lot of bike. Joe built this for a long term customer (6.5″ in stature) who wanted a gearbox mountain bike. The customer provided the EffiGEAR and tubing and Joe built a frame around it. Joe is already building a second prototype and hopes there’s some demand for this exciting bike.

Joe’s thoughts on frame design

Starling Cycles have some pretty rapid riders out there on the UK Enduro racing scene, Dan Bishop for example, an absolute pinner taking the top step all over the country on his hand-built Murmur set-up. I asked Joe how the riders get on with tyre clearance and the flex that comes naturally with any steel frame bicycle.

“Flex is good. It is essentially sideways suspension.” – Joe Mcewan

“Flex is good. They do move a bit, but let me tell you about that [flex]. Imagine you are riding your bike downhill, in a straight line, with all my suspension working. In that case, it is good that your bike is stiff because it allows the suspension to move. If the bike is moving and flexing then it is taking away from the suspension. Then you go around a corner. The forces from the ground act normal to the ground, so they’re acting vertically. If your bike is a 45 degrees, half of the ground forces go up the forks and into the suspension, the other half bend the frame. So if you have a really stiff bike and you go over a bump going around a corner, the suspension has to move twice as far to take that bump out. Alternatively, you can let the bike move a little bit. It is essentially sideways suspension. As your bike is leaned over, it gives you some sideways suspension. If you read the reviews of my bikes, they all talk about loads of grip in off camber sections – it is because of the flex. It is easy to go in a straight line isn’t it. It is going around corners that is hard, so design your bikes to go around corners. People think stiff bikes pedal faster – it makes a tiny difference but it doesn’t take away from the power.”

We then went onto the topic of the anti-squat characteristics of the bikes.

“Lots of people get confused by anti-squat. To me, anti-squat is to do with… as you move your weight and accelerate forward, or when you slam your brakes on, it is how that affects the suspension. People think that bikes should be designed so that when you accelerate or brake, the suspension pulls the back wheel in. The thinking is that that is a good way to do it. I think if your chain line is in line with your pivot, there is no movement anyway when you pedal. It is not like you are on a motorbike and you’re accelerating rapidly and the weight shift is massive. To me we should design bikes to be as neutral as possible. Weight shift shouldn’t affect the suspension. I think that is another reason our bikes ride nicely, is because they don’t do anything strange.”

“I’ve said this a lot recently, but what do you think makes a bike fast? It’s a bit of a trick question. It’s the rider! The rider determines how fast the bike goes, it isn’t the bike. If you design a bike to be as understandable as possible, so it is simple and doesn’t do anything strange – we have linear leverage ratios, the shock doesn’t do anything strange, the geometry is all balanced.”

“People think full suspension bikes should be designed to be soft at the start [of the travel], give some support in the middle, and then ramp up at the end. The only reason you need it to be soft at the start is to give a bit of small bump sensitivity. That makes sense. You need support in the middle – that make sense. You need it ramp up at the end, but that only really matters if you’re hitting really big features. I occasionally bottom my bike out, and it isn’t harsh. There’s a bit of give in the steel so it isn’t a harsh bottom out. It is not a big bang. If you have a weird leverage ratio – having it soft and then going firm – if you speak to any suspension tuners, they can’t tune a shock to work properly like that. It is complicated to get the shims in the shock to work for a leverage ratio that is odd. Whereas if it is linear through the full travel, they can just shim it to be soft at the start, and then firm up as it is moving more quickly. It is easy for them to tune a shock like that.”

“I’ve actually been thinking about coil shocks. An air spring, because it has a little bit of stiction at the start, you have to run it a little bit softer to get over that stiction. And then when you do get through that stiction, it actually goes soft, and that is why you’ll feel it sort of wallows in the middle and you don’t get a lot of mid-stroke support. A coil – because it is soft at the start you can run a slightly harder spring essentially, compared to the air, and then you get more mid-stroke support. So the coils are brilliant at giving support in the middle, and that is what matters. You design bikes to be good for the rider. So if it is sensible and it is giving you that support in the middle and it is not diving you’re happy – your body can deal with small bumps. All my personal bikes run with coils now.”

Pricing and Availability

Starling Cycles sell direct to consumer only. Predominantly, they sell just frames and shocks, but can provide parts from Rockshox, DVO, Ohlins, Burgtec, Funn, BikeYoke, Hope, Magura, Middleburn and Shimano to achieve a full build if necessary. The Taiwanese made standard sized Factory Murmur frame with a RockShox Debonair shock will set you back £1850 (~$2090). All other frames are custom sized and UK made, these start at £2040 (~$2300), frame only.

All frames can be powder coated in one of several different custom colours for no additional cost. That’s with the exception of the Murmur Factory which comes in Primer Grey with black graphics as standard – you pay an extra £125 for your choice of several custom colours.