Not only are the new Industry Nine Pillar carbon wheels the first hookless rim design for the companies involved, but the wheels also represent the first completely US made carbon wheelset for the brand. With the exception of the bearings and o-rings, the Pillar wheels get the made-in-the-US moniker thanks to the new hookless carbon rims that are made possible by their collaboration with Reynolds. As one of the first mountain bike rims that Reynolds is manufacturing in the US, the rims use a design by Industry Nine.

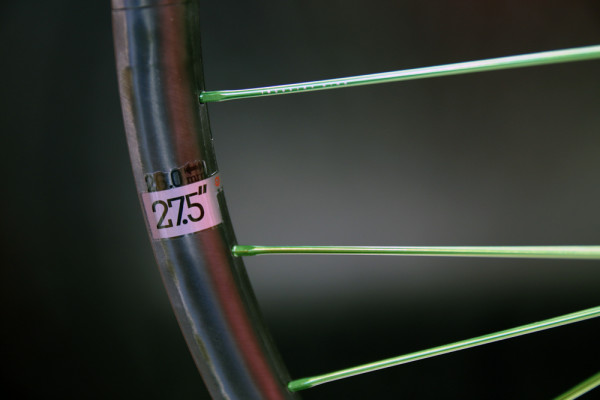

Still largely in the preproduction phase, I9 plans to have four different models available in both 27.5 and 29″ sizes. Matched with Industry Nine’s legendary hubs and aluminum spokes, the wheels are designed to provide excellent stiffness, ride, and durability while staying a light as possible.

When you think of the pillar, think of strong columns that rise straight up – sort of like the hookless sidewall design of the carbon rims. In addition to not requiring any post machining, the hookless design allows Reynolds to run continuous fiber through the impact zone of the side wall for a rim that tests extremely high in sidewall impact resistance.

When it came to the design of the rim one of the big characteristics that I9 was looking for was specifically ride quality. Feeling that many deep carbon rims contribute to a wooden ride feel, I9 instead uses a 21.5/22mm deep carbon rim along with a layup specifically tuned for better compliance.

Inside the rim, the Pillars use a 2-3 degree chamfer for bead fit that will allow for easy tubeless set up. The rims will not have an aggressive bead shelf on the inside to make removing the tires easier. According to Jacob McGahey at Industry Nine, the main cause of burping tires is caused by the bead being pulled out elastically, so the tire should have no problem staying seated with the design.

On the 29″ side, I9 will offer the Pillar ulc (ultra light carbon), and the trc (trail carbon). Both rims use 24mm internal and 28mm external dimensions, the ulc saves weight by only using 24 spokes instead of the trc’s 32. That means 1355g for the ulc wheelset and 1495g for the trc. The rims also offer a bit of weight difference with the ulc rim weighing 345g and the trail at 365g. The lighter ulc rim does come with a 220 lbs weight limit while the trc ups it to 250 lbs.

The Pillar 27.5 have a similar break down, only between trail and enduro with the trc and enc. Again, both rims use a 26mm internal width with a 31mm outer for a more aggressive build and 375/400g rims. Complete weights are listed at 1395g for the trc and 1525 for the enc. In addition to differences in the carbon layup, weight differences come from the spokes with 24 for the trc and 32 for the enc.

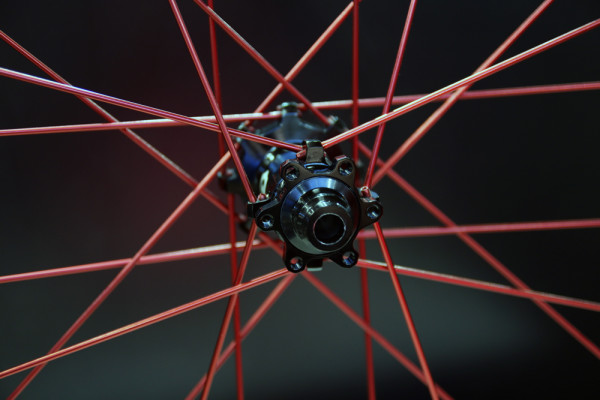

Built with Industry Nine’s Torch hubs, all the wheelsets use their aluminum spokes in standard (all red or all black) and custom colors (additional fee for custom). The hubs will fit pretty much any axle standard on the market including Lefty and single speed specific in certain applications. Other options include hybrid ceramic bearing upgrades, XD freehubs, and custom lacing options.

Take your pick of the new wheels, with standard options all four will retail for $2850.

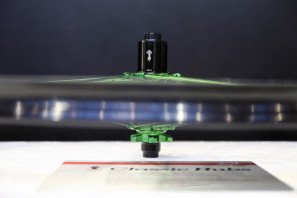

Also lurking in their booth were some new hubs specifically for the Trek Boost 148 standard. Along with a few bikes, Trek recently introduced a new “standard” for rear axle spacing specifically for 29ers. Called Boost 148, the hubs are 148mm wide instead of 142 which offers 6mm of extra flange spacing for an improved bracing angle of the spokes. According to Jacob, that small of a change results in 15-20% more stiffness out of the wheel, hub, and spokes with only a 7g weight penalty. Yes, the design requires new hubs, but Jacob mentions that from and engineering perspective the design makes a lot of sense.

Already have a set of I9 wheels and planning on buying a bike with the Boost 148 standard? You can send your wheel or hub into Industry Nine and they will replace the hub shell and axle to work with the wider spacing. That may sound expensive, but the freehub body and the drive ring are what cost the most for I9 to produce so buying a new hub shell and axle is actually cheaper than a new freehub.

New Boost 148 hubs run the same price as the other Torch hubs and are available with the same options.

Last but not least, is this sneak peek of their complete fat bike wheelset. While they are still deciding on the final rim for spec, the wheels will use the aluminum spokes and I9 hubs to offer fat bike wheels ready to roll with 135, 150, or 170, or 190 spacing in all axle configurations. Keep an eye out for more details on these in the future.