From the sparkly new to the well established, SRAM’s roots in Taiwan run deep. Well, SRAM does have a long history of manufacturing on the island, but in this case a lot of that history belongs to Truvativ. After SRAM purchased the company in 2004, the facility remained and is now the hub of much of SRAM’s carbon fiber production. Of course many of the Truvativ products that are still being produced or have morphed into similar parts under the SRAM name are made here as well.

Jump inside for a quick spin through the facility…

Technically serving as the second SRAM factory in Taiwan, the Truvativ facility has grown 10 times the original footprint. Located a short bus ride away from the Shen Kang factory we visited in part 1, the Truvativ factory seems more rural with a sprawling series of buildings flanked by rice fields and other industrial buildings.

Not the most architecturally stunning complex on the outside, inside each corrugated metal building lies a streamlined production process based on manufacturing principles like TQM, TPM, and TPS. All of which are designed to create a process that relies on just-in-time inventory sourcing and ensures consistent quality.

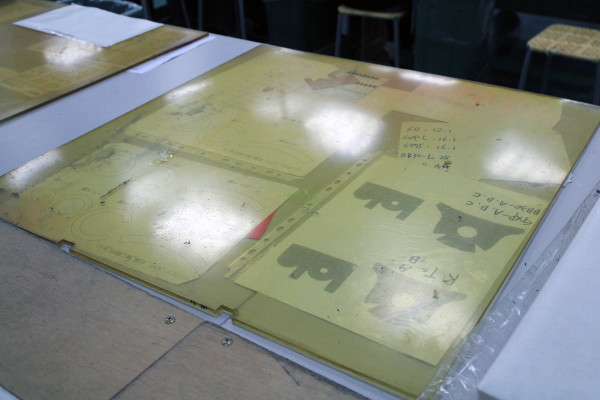

Like other carbon fiber production we’ve seen, it all starts in the cutting room – though on a fairly large scale.

Raw sheets of carbon are cut from rolls stored in the walk-in freezer and then trimmed to precise dimensions by machine or by hand.

For their cranksets, workers assemble 3 piece inner structures which are then carefully wrapped by an army of employees. We weren’t provided the specifics with how those structures are removed from the crank arms during manufacturing, but the result is a fully hollow carbon crank arm. In the background employees are wrapping the carbon plies around steerer tube and fork crown assemblies.

Once all the raw carbon is put in place, all of the components are placed into heavy steel molds that are loaded into presses with multiple bays where the carbon fiber is cured.

When the curing is complete, the molds are cracked open, and the carbon has taken shape but still needs a lot of work. Empty molds are sent to this giant cleaning machine where they are scrubbed free of any excess resin and put back into rotation.

Once the carbon has emerged from the molds, what was generally a pretty clean process turns dusty in a hurry. First, excess resin is trimmed from the finished pieces by hand and file. Next, it’s a series of sanding and polishing done by hand or on large industrial grinders fitted with sanding wheels or wire brushes.

Carbon components show up to the decal room smooth and ready for their final shine. Decals are installed by hand followed by a glossy clear coat to protect the carbon.

Stepping into the Truvativ side of the factory, the battery of CNC machines turns out SRAM products like chainrings and aluminum cranks (after forging). Machinery ranges from fairly standard CNC workhorses to advanced CNC machines and lathes.

I’ll never tire of seeing raw chunks of material turned into beautifully finished parts and a pile of chips.

In yet another building, products are laser etched in house. This wall of examples gives an idea of just how many aluminum parts are manufactured here.

GXP bottom brackets are manufactured here as well, with the manufacturing process a perfect example of SRAM’s cost savings implemented through automation. Assembly of the bottom bracket cups previously required 6 people and 75 seconds per piece. The new machine is operated by two people, and shortened the cycle time to 20 seconds.

Other Truvativ parts and accessories like the Stevie Smith receive their finishing touches and are packed for shipping.

Even after three installments, hours of notes, memory cards worth of photos, and one long, impressively orchestrated day of tours, it’s hard to feel like we are not just barely scratching the surface of SRAM’s presence in Taiwan. Truly a giant in the bicycle world, they play an integral part in the A-Team’s supply chain that allows much of the bicycle industry’s production to function as it does. We’d like to thank SRAM’s Michael Zellman and David Zimberoff for organizing the tour, and can’t wait until we can visit again.

Factory Tour: SRAM’s Taiwanese Manufacturing Part 1 – RockShox Suspension, SRAM Drive Train, More

Factory Tour: SRAM Taiwan Part 2 – All New Asia Development Center