This year for NAHBS coverage, we’re taking the opportunity to interview a select number of brands that produce bicycle adjacent products. Abbey Bike Tools is the first in that series.

It sounds cliche to call a product race-tuned and pro-tour tested, but Abbey Bike Tools are literally just that. The first product in the line, the Crombie Tool, was conceived by a pair of race mechanics, a group of chronically under-appreciated professionals who constantly cobble together special tools and equipment for their work. Today, Abbey tools can be found in the professional and private tool boxes of mechanics throughout the professional circuit. Abbey has really set itself apart by not just creating clever functional solutions, but by elevating the fit, feel, and finish of its product to a level worthy of their professional audience. The tools work, they are designed to be beautiful and feel nice in your hands, and they are reliable for when mechanics and athletes need them most.

The main man behind the brand is Jason Quade, a veteran of the race circuit himself. In this interview, we discuss the origins of Abbey tools and what it’s like to have a problem like Titanium Hammers…

BIKERUMOR: How did you develop your first tool? Were you a mechanic?

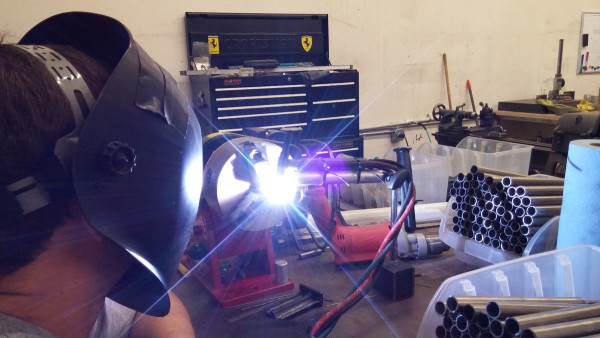

JASON: I definitely did start out working in bike shops as a punk ass kid in my hometown of Columbia Missouri. I moved to Oklahoma to go to welding school with this double-edged approach: I can either go get a job in industry or maybe there is some light at the end of the tunnel and I can work for a bike manufacturer. My first welding job was building pressure vessels for the power generation industry. Everything from nuclear plants to old-school coal retrofits. So that was cool. It was like this side of heavy industry where thin materials for us were like half an inch thick, you know? But yeah, came out to Oregon and that’s kind of when I got sucked back into the bike industry. Had a couple of fabrication welding jobs here. One of them in aviation. One of them doing some random stuff, hand rails and whatnot.

BIKERUMOR: When you say “industry” you mean general industry… not bike industry.

JASON: Yeah. Industry-industry, not cycling industry. So yeah, then the economy tanked. Airplanes are kind of slimy, both in business and by nature, and so I got laid off from there. That’s when I went back to work at the bike shop. It was a completely different feel. Bikes weren’t toys like they were in the Midwest. I started doing some stuff with the local races, Cascade Cycling Classic. At the time we were having a bunch of road and cyclocross-oriented national championship events so I got tagged to help out with those things with whoever was doing neutral support or a team.

Then I went to the Race Mechanic Clinic that USA Cycling puts on every winter. And that’s when I met this guy named Jeff Crombie. Jeff also used to work in aviation as an airframe repair mechanic on helicopters. We had this common interest of aviation and a proper way to do things. In aviation, if it’s not right, aircraft can fall out of the sky and typically, when that happens, people die. They tend to go through a lot of documentation and procedures to make sure those kinds of things A.) don’t happen and B.) when they do happen, they can follow the paper trail back.

So Jeff and I crossed paths over the next couple of race seasons and I got a phone call from him asking me to make a custom tool for him. It is now what is the Crombie Tool. So we hogged out a couple non-standard cassette lockring tools, welded flat bar handles to them, and that was the very beginning of it. And then I started getting phone calls from some random people who were also race mechanics and floated in and out of that circle and I thought, huh, maybe there’s something to this. So we worked with a local CNC shop here that was great to us and really helped us.

BIKERUMOR: So I have to ask, were you making tools ahead of time? Before you were asked to go down the tunnel of the Crombie Tool. Is there a reason why you were tapped for that?

JASON: Yeah, he knew that I had a background in making stuff, so he called me up and basically said, you know, “do you think that you can do this?” And yeah, that was that. So I had definitely made tools when I was working within the fabrication shops, just things we needed to do our job, but it wasn’t like they were production finished tools. I don’t have a background as a tool and die maker, which is what some people associate with a traditional like, “I’m a toolmaker.” But a lot of the stuff that we need to do isn’t super complicated, somebody else comes up with a part that dictates a tool pattern, and the nature of what we do is we follow that, and work around their parameters, and you know at that point it’s just product testing.

So it’s not too much different than anybody else that makes bike parts. We’ve designed this thing and we have to run it through the ringer to feel confident about it working in the field and that’s that.

BIKERUMOR: I remember when the Crombie Tool came out… many of my friends are mechanics, and it was like, finally, there was some fashionable bike toy for them. Everyone else had all these fashionable bike things… the mechanics finally have something functional and cool and a little bit out of the typical.

JASON: Yeah, it’s definitely not mainstream stuff. That one tool that Jeff asked me to make was basically the start of the business, but it was really – the execution… If we had come out with what people were expecting as the common quality level for bike tools, it probably wouldn’t be where it’s at today. We do things better. The bike industry as a whole, whether it’s a manufacturer like Campagnolo or the custom builder crowd or the big mass production houses building hundreds of thousands of bikes, they all really stepped up their game in the past ten, fifteen years, and the toolmakers haven’t. They haven’t even tried. Certainly they have come out with new tools to deal with all these crazy new fitments, the “bottom bracket of the month” kind of thing, but they haven’t really increased their quality level like their peers in the bike industry did. And that’s the thing that we shoot to do. Silca – there’s somebody else that’s doing the same thing, really upping the game of quality and craftsmanship in pumps, which is something that we’ve all taken for granted. So that’s kind of where we are at with it.

BIKERUMOR: I mean, it’s exciting to see that blowing up in different realms. What does your operation look like? Are you CNCing things on-site, treating things on-site?

JASON: Not yet. So all that stuff is – so we manufacture everything only in the US, everything from raw materials to anodizing to engraving is all done here. The vast majority of it is done within our desert isle of communities in central Oregon, which is geographically isolated a little bit. Sometimes it gets a little tough to find a good vendor, so we’ve got to go – like anodizing has been a huge problem for us, but we’ve finally tracked somebody down in central California. Which, it kind of sucks to send stuff back and forth, but it’s what we need to do to get good quality work. So it’s what we need to do. We are definitely a manufacturing-oriented company so the goal is definitely to bring that kind of stuff in house.

Right now, all of the production CNC work is done by one of a couple local vendors here, which is nice that we can go down there and look at brand new parts that are coming off the machine and we can tweak and tune things, and it doesn’t involve a 12 hour plane flight to Taipei. The other goal is to bring some of that stuff in house so it makes financial sense. For sure we want to do all that stuff, but at the same time it’s gotta make money because we don’t have some lottery ticket backer.

BIKERUMOR: How is your personal approach to tools evolving? Are you settling into a style or a certain aesthetic or feel as things are going along? Or are they process-specific. If you re-did the Crombie Tool today, would it be different?

JASON: You know, it’s a constant evolution. To answer that question first, I wouldn’t change anything about the Crombie Tool. I think that that tool is what we built the brand on and it’s a great cornerstone product for us. It’s extremely rare that people break them… it usually involves a square taper seized Campagnolo bottom bracket and a cheater bar. The end result of the Crombie tool is definitely pretty much the same, but there are things that we’ve done to speed up manufacturing and try to make them a little easier to produce. The chain whip kinda had a rough start, had some durability issues and so we made a change, and then made another tweak to make them easier to make. Out of the version we’ve had now for about 18 months, not a single warranty or inquiry on those. So at this point, they are super dialed. And they go together easily, which is another biggie for us.

You know, in terms of the design aesthetic, I have a couple of rules. No black oxide- it drives me nuts. It looks cheap and it’s kind of effective, it has decent rust protection but it’s not great. And I hate plate steel handles. Like you said with the pedal wrench, it feels good in your hand because it’s big and hefty. It’s still got a laser cut steel part in it, but we put the wood around it to make it something comfortable.

Other than that, the finger spline that we use on our bottom bracket sockets and the truing stand adapters, that’s a common theme throughout a decent number of our products that we do for people who have greasy hands and you don’t always have a good grip to start a thread, so put something on there that gives you a pattern there but is not necessarily a knurled finish. We’ve got some other tools that will probably end up with some wood integrated in there, and I think that’s a great classic tool feature. It’s like tools that your grandpa had. I remember my grandpa’s toolbox was full of wood-handled screwdrivers and stuff.

BIKERUMOR: And when they get oily and they get all seasoned…

JASON: The pedal wrench definitely will take on some pretty good patina after a few months of use.

BIKERUMOR: That’s something you can look forward to aging with you, you know? At what point did you decide that this was going to be a company and a full-time job for you?

JASON: That was kind of a something that was more forced upon me than a decision that I made. And it was you know, Zach [Overholt], and Nick Legan, wrote initial press reviews, which ended with this whole quote that was like “an heirloom quality tool.” And at the time, he was one of my favorite tech writers, so to have him say that about something that I made was kind of like this proud dad moment. So when those two pieces of press came back, we started getting flooded with emails and whatnot, and the one thing that 20-30% of the people put in their email was “what else do you make?”

And it wasn’t until that point that I’d even thought that there was potentially a business around this one product. Thought it was maybe going to be a flash in the pan. I’d sell one of these to every race mechanic in the world, I’d sell maybe 1000 of these things and I’d be done. So when people kept saying that, I was like huh, maybe there is something here and then we came to terms with Crombie Tool production. Got a couple of the things that seemed like low hanging fruit. We did the first version of the chain whip. Then people kept asking, can you make this? Can you make a hanger tool? That was probably the most requested tool and it’s another cornerstone product for us. It really stands out amongst the other tools used for that task.

BIKERUMOR: How many people are involved in your operation when you say “we?”

JASON: There’s three of us and the dog. Yeah, he dictates the work schedule, that’s for sure, like when break time is. I have a partner, John, who does more the business side of things, which has definitely been the hardest part of this. Like, how do you make a business around a couple of products? He’s been great to work with over the past two years… two and a half. And we have a guy that helps me out on the production side of things. It’s still not big, it’s bigger than your one man frame builder operation, but it’s not a huge thing.

BIKERUMOR: That’s super cool. So are you bringing something cool for the show this year?

JASON: We’re bringing a Wash Buddy. Our involvement with racing means a lot of the product ideas come from there. The original Crombie Tool came from there. The Wash Buddy was designed and tested with the help of SmartStop who we worked with last year. We’re also going to have production bearing presses. We showed it off at Interbike, and we’ll have full-fledged production versions there and versions to sell as well. We’ll have those two. And the Wash Buddy has a quick release skewer that we’ve done in conjunction with PAUL. It’ll be just a one-off deal to use their skewer in it. We’ll do a limited batch for the show and that will probably be it. And then we’ll bring that tool back to life with a different skewer. There’s just a couple other things… we might bring some kind of one-off Titanium Hammers. Limited edition versions of our production Titanium Hammers, maybe with some carbon to make it a little more absurd.

BIKERUMOR: Are you still excited about everything? I mean, you’re doing silly stuff… you must be having a good time.

JASON: Yeah. That’s what happens when there isn’t anyone around me to tell me “no.” There isn’t an accountant in an office telling me that no, you can’t have that thousand dollars to do that weird project that will never make us money. And that’s the Titanium Hammer. A world tour race mechanic customer of ours made us make that. I thought it was the dumbest thing anyone had ever asked us to make. And then I made one and it was like, this thing is awesome!

BIKERUMOR: Do you have one for yourself?

JASON: We have two in the shop. We use them every day. They are great in the machine shop, in the manual machines, because they are light and have a soft face. It’s my favorite tool to make and one of my favorites to use just because it’s so versatile. Yeah, and then I showed the Ti Hammer to a friend that was working for the Shimano program at the time, he just fell in love with it. He really pushed me to put it into production. Basically wouldn’t take no for an answer.

The conversation went, “I want one.”

“Well you can’t have one.”

“Well, you made one, right?”

“Yeah.”

“Well make another one.”

“It’ll be expensive.”

“How expensive?”

So I threw out a number that I thought would make him reconsider. He was like, “Alright.” So I made a limited batch of 50 and there were enough people that didn’t order one in time, so now they are a regular product for us. I never really thought there would be a need for a Titanium Hammer but it’s one of those things that’s a lust-worthy item. I’m sure it was on a lot of Christmas lists.

BIKERUMOR: Do you ever get fan mail from other mechanics?

JASON: Yeah. We do see some stuff on the social media and whatnot where people are getting excited about their tools and so yeah, that’s kind of nice. We always, you know, it’s not uncommon to get random tool ideas from people. Sometimes they are awesome ideas. Sometimes, I’m like man, I really do not see a market for that at all. But you know, that’s the bike industry. THEY see a need for it so there is obviously some market. But how many people think like that?

BIKERUMOR: Is it five people? Is it… six people?

JASON: Like a square taper crank puller is one that we get. Every time we go to a show as many as half a dozen people ask us for that tool. It’s like, I haven’t owned a bike with a square taper crank or even an Octalink ISIS crank in like ten years. I do own one of those tools. I couldn’t tell you exactly where that’s at. And most people that need that tool already own it. So they make that argument that the ones that are out there break or don’t work all that well. So you’re buying the same tool you’re not happy with over and over and over again because it’s the only tool.

But there are so many bikes with square taper that the need for that tool isn’t going to completely go away, even though there’s not much need for it on the racing side of things, which is where the bulk of my experience has been in the past five years.

BIKERUMOR: I like how you are simultaneously kind of making fun of it AND defending it.

JASON: One of the challenges of product design is making things that I personally see zero need for. Like, well, I fix bikes one way and I’ve done it that way for fifteen years. I pick up new things every once in awhile but I’m not going to change my personal system because some self-proclaimed expert tells me I have to do it another way. If there are enough people that think that way, we need to make tools to accommodate that.

BIKERUMOR: So what do you tell the kid at the show that wants to be you when they grow up, who wants to grow up to do what you do? What advice do you give them?

JASON: I think the biggest thing that you’ve got to do is to start. There’s so much yip yacking and talking about it. You have to learn the skillset. You just have to start. You have to stay honest to yourself and to the brand that you’re building and you have to find a hole that there is actually a need for. Those are the two biggies.

BIKERUMOR: I like “You have to find the hole there is actually a need for.” You’re talking about a market that’s arguably pretty saturated with tools… there arguably isn’t really a “need” for your product. I mean, but there is…

JASON: There is and there isn’t a need. We get two kinds of people that approach us at the expo. There’s the kind of person that is fed up and has had enough of the staple tools selection in the bike industry. They say, “The quality has gone downhill, this thing is junk,” whatever their comments are. And then there are some people who just don’t get what we do. The first person sees us as an answer to that problem the other tool manufacturers have created. The second person doesn’t get it, “I can go get this tool for $4 and it does the same thing.” I’m like, “It ALMOST does the same thing, and that guy is over there in booth, you know, 39567. And he will gladly sell you the $4 version.”

Early on we tried to convert those people. And now, there’s that line in the sand. They don’t quite get what we’re about and that’s fine. It is what it is. Not everybody’s going to be our customer. We’re positioned at the top of the market and we’re aware of that. We’re not going to appeal to everybody. But at the same time, we don’t want to cut corners.

BIKE RUMOR: The other question, and this is kind of out of scope, entering the market with this alien approach to tool making, because you’ve got big players doing their thing, and you move into this space at this completely different level – way out in left field. Is there this internal hope that you pull tooling up? You’ve already elevated tools for yourself and you’re a mechanic – is that the influence you’d like to see your product have on the larger category?

JASON: I don’t think it’s unattainable – if somebody wanted to directly compete with us. At the end of the day, the one thing that sets us apart and allows us to do what we do is that we think that it matters and we care enough to actually do it. Other than that, it’s not like I’m over here learning how to develop processes to weld Beryllium. We’re not developing new technologies to manufacture bicycle tools or creating some new crazy custom tool steels to do it with. It’s using things that are already there and somewhat proven in similar applications in industry, and applying them to what we need to do. Yeah, we’re definitely – and I don’t know if saying that we’re in left field purely based on price is appropriate…

BIKERUMOR: No, no, no, I think it’s about approach. You’re not looking at this like it’s a larger established collection that’s hanging on a wall with a bunch of matching product. You’re not looking at the inexpensive product that will allow the beginner home mechanic to work. You not only have this product and elevate it in terms of quality and approach and human interface and function, but you don’t give pro pricing to mechanics in the bike shops. They are your customer, you know? That’s where you put the tool. You’ve taken it out of this previously established context, is what I’m saying.

JASON: And that’s been a tough uphill battle to bring that distribution strategy into the industry. We get a ton of people asking if we do EP because our industry is kind of built around that.

BIKERUMOR: That’s the benefit that makes it okay to not pay mechanics, right? Which is unfortunate. It’s indentured servitude… but it’s okay – it’s bikes, so it’s okay.

JASON: Yeah, I hate that, I hate that cop-out. I hate that excuse for why we can’t pay somebody a decent living and as a bike mechanic the barrier to entry is really, really low, but at the same time it brings the ceiling down because the guys that are really good at what they do aren’t making so much. But yeah, it’s tough and it’s something that I think that as we grow and have time to take on those types of projects that I’d love to work with somebody to do, training programs and whatnot, there’s been training programs around the industry, that we’ve chatted with, the guys at the United Bike Institute, and the John Barnet and other guys about doing collaborative training programs just in order to continue to raise the bar. I don’t know if there is a concise way to do it. The NBDA was talking about doing a certification program. We’ll see if that ever gets off the ground.

BIKERUMOR: Do you have sponsored mechanics? Sponsored pros?

JASON: We typically work with one team or team ownership group. Unfortunately, with the nature of bike racing, we’ve been doing this for three years and we’re on our third team. For us, it’s where we come from and those guys were our first adopters. We’ve got customers on 15 of the different world tour teams. There are only 17 of them, I think. Maybe 18? We had one just yesterday send me an email and order tools for their entire mechanical staff. That’s the kind of trust we have with those people to deliver product for when time matters and results pay the bills, you don’t necessarily want to trust that bike repair, those tools to just anybody.

BIKERUMOR: Is that what you want to tell the guy who wants the four dollar wrench at the trade show? Is that’s what’s going through your head when he’s talking to you?

JASON: “You’re obviously not trying to win the Tour de France.”

BIKERUMOR: Ha!

JASON: I can be a little bit of an ass. It’s definitely crossed my mind from time to time.

BIKERUMOR: You’re a mechanic, it’s fine!

JASON: Kind of par for the course. It’s almost part of what you tell these people to get them to convert. It ends up being such a time suck. I would sit down and have a cup of coffee with this guy for an hour if I had nothing to do. It would be awesome to convert, to have an adult conversation with someone like that. But when you’re at a show and there is a new interaction every two minutes, you kind of need to be, “Hey, we chucked this golf ball into the woods, we really shanked the hell out of that one. Let’s just take a drop of a new ball. I’m not going to waste my time going into the woods for it.”

BIKERUMOR: A… golf analogy?

JASON: I’ve never played a hole of golf in my life.