Predator Cycles first came to our attention at NAHBS last year thanks to their gargantuan The Major one-piece carbon fiber road bike stem and handlebar. So, when some extra time presented itself at LAX, founder Aram Goganian picked me up for a quick tour and legit burrito (thanks man!).

Predator Cycles is a small carbon repair shop that also makes frames and the aforementioned bar/stem combo. A mountain bike version of it debuted recently, too.

Aram got into carbon fiber working on parts for cars around 2003-4 at the end of high school. He continued messing with composites, but only for his work with another company. When his noncompete ran out in 2010, he immediately sold all remaining alloy tubes, parts and tools and switched Predator to 100% carbon fiber. While he says it may not have been the best short term business move, it’s paid off now with a booming carbon repair business…

The shop’s pretty small, with a good portion of it dedicated to office space, bike storage and a basic fit setup. All the carbon repair and building is done in the back.

A homebrewed vacuum system keeps dust at bay. While there’s a lot of stuff laying around and the system ain’t much to look at, there was less of a dust film here than in some major brands’ factories we’ve seen. DIY FTW!

Aram started building bikes when he was 14 after wondering aloud how hard it could be to make a TT bike and someone suggested he try. It was, he admits, a hot mess of tig welded aluminum. It’s been reprinted and fixed up a bit since, but it’s still rideable 13 years later.

Several of his early frames still hang on the wall, along with a few other prizes like a purple Zipp triathlon frame. Now, though, it’s all carbon.

For complete bikes, some of their tubes are made by ENVE, the others are made custom in house on their own mandrels. They’re getting their mandrels coated in Teflon to make the tubes easier to remove, which should reduce errors and waste, and they’re starting to make headtubes and bottom brackets in house, too.

And they’re working on an aero tubeset, which is being developed for a new frame that’ll be their first bike that’s made with tubes and parts made 100% in house.

The goal is a complete monocoque frame with seatmast will be under 800g for the track version. A TT road version will be slightly heavier because of the added cable stops and such. It’s still in development, but price (keeping in mind it’s full custom) will be around $10,000 to $12,000. Aram says it should produce a “13 pound track frame bike that’s stiffer than God Almighty. Why? Because we can. And because it’ll be cool.”

They’ll also offer a tube to tube version that won’t be quite so expensive…closer to their $3,995 price tag for a full custom road bike frame.

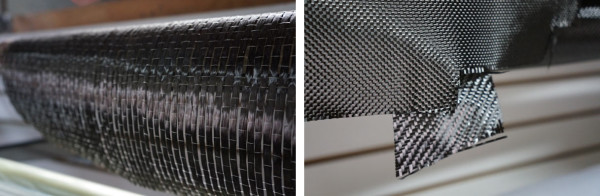

Carbon spools are high mod (pink) and ultra high (92) in the foreground, standard mod in the background. The UHM is used when they make their own tubes, but has to be “comforted” with standard mod to make it practical for use. Aram says it’s like glass, very stiff and strong, but one good impact and it’ll shatter. So, it’s mainly used where there’s a lot of static load, like at the bottom bracket and headtube.

Colored Kevlar is an upgrade option for The Majors. Aram says it’s a $150 up charge not only because of material costs but also because it’s really, really hard to cut and work with.

They’re working on their own full carbon and carbon/Kevlar dropouts and will have disc brake placements outside the rear triangle. Aram Goganian says putting them inside the rear triangle as shown on the ‘cross bike prototype further down creates a lot of fit and clearance issues with all the custom angles and geometries they deal with.

The bulk of his business is carbon repairs. Part of that is actually repairing bikes that the owner wants to keep, like the ones shown immediately below. The Cannondale in this box came off a roof rack at 70mph then got hit by another car. They’ll be putting it back together and raced by Daniel Ramsey to show how well their repaired bikes hold up. More on that in a minute…

Smaller frame cracks and dings are more common. Carbon repairs start at $180, and small cracks go from their up to about $300. Cracks that go all the way around are about $350, and pieces missing from the frame begin around $400 and go up from there. A form on their website will let you submit photos and give you an estimate via email. Repairs usually take about two to three weeks. They’ll do wheel repairs, too, as long as its not on the braking surface.

Depending on the repair, up to 80% of the paint may need to be removed. Once it’s all fixed up, they’ll send it to one of three different places for paint.

Even when not covered in paint, a fresh clear coat makes it hard to tell anything ever happened.

The other part of the repair business is a round about way of team support. If a frame’s owner is ready to just get a new one, Aram will take the old frame, refurbish it and put it under a racer. The Orbea repair (above) had a small crack in the downtube near the BB.

This Cannondale had a completely smashed seatstay.

Aram is a big supporter of racing, sponsoring a full team with travel support and much more, including bikes. He’s got Emile Abraham, Cody O’Reilly, Kirk Carlson and Cesar Grajales racing Carbon Repair frames. And “Fast Freddie” Rodriguez is racing on The Major handlebars.

A glossy coat of paint makes it look just like new, and if it can hold up to those guys’ efforts, his repairs can most likely handle anything you or I are like to pump out.

The Major handlebars start off with an FSA OS99 stem with the bolt heads at the face cut off. Handlebar is placed and set into position, then fixed into a jig and the remaining front portion of the stem is cut off. Depending on stem length, about 1.5″ to 2″ of stem is left sticking out from the steerer tube clamp. Next, a 3/32″ layer of fiberglass is wrapped and bonded around the alloy stem. This is to insulate the carbon and alloy from interacting with each other. The two materials can trade electrons, which will cause delamination, so this sets it up for solid, long term durability. Then a Kevlar structure is built to connect the bar and stem stub. This gives it really good impact strength and kills vibration. Originally, it was a full carbon fiber build, but riders said it was too stiff and transmitted to much vibration, causing hands to go numb occasionally. The Kevlar fixed that while only adding about 15 grams. Aram likens the material to steel – it’s strong and has a lively feel, but it needs something else to make it ride right.

So, after the Kevlar, it’s wrapped in carbon to make it stiff and snappy. At this point, it looks like a “T” and the handlebar and stem are one piece. It’s then vacuum cured for 24 hours, at which point is it’s a rideable unit. But it’s not done yet.

Lastly, they put foam forms on and wrap the large triangular gussett on it to make it insanely stiff. It’s between three and six layers of full carbon fiber, sometimes with a quasi-aesthetic carbon Kevlar outer layer, depending on the customer’s riding style and preferences (and budget, as mentioned). Once it’s vacuum cured, the internal forms are dissolved, leaving a hollow section. Then it’s heat cured at 180° for six hours, which discolors the resin a bit, so it’s then given a final cosmetic layer.

The work with dry carbon fiber only, using a wet layup when they add the resin. This is done rather than prepreg because prepreg would require much hotter cure temperatures, which could damage the already cured carbon handlebar. Frame repairs are air cured only because any additional heat could weaken the frame and crack or yellow the clearcoat.

The mountain bike Major doesn’t get the same massive triangle box section, but keeps with the FSA base parts.

The Aerodinamico is their TT version for triathletes and time trialists. At $999.95, it’s on the high end of what a carbon aero bar and extensions set would cost, but it’s built full custom just for you.

Before we get to the custom frames, it’s worth showing a few other goodies. Seems everyone that knows how to work with carbon fiber likes to tinker with it and make simple things out of carbon. Like frame pump holders…

…and espresso cups and saucers.

Aram had built a disc brake version of their road bike in 2012, but this cyclocross prototype took on a few design cues specifically for the grass, mud and snow.

A small cutaway gets the rear tire up close for snappy handling. May not allow for as much compliance, but that can always be built into the seat mast, right? Up front is a tapered head tube with ENVE’s CX disc fork.

Any of their frames can be made for mechanical or Di2 routing, and this one’s ISP (integrated seat post, aka ‘seat mast’) was made to hold Shimano’s internal seat post battery.

Lower set seatstays without a brake bridge should provide a bit more compliance, but the shorter overall length should help with lateral stiffness.

Huge thanks to Aram for showing me around and saving me from waiting around the airport between trips! Keep up the good work.