We got the story of Festka’s new titanium frames in our pre-NAHBS interview, which took a deeper look at the new material and their nabbing of Morati’s founder to head things up. Now, we’ve got eyes on with the new frames plus so much more. Festka’s been quite busy.

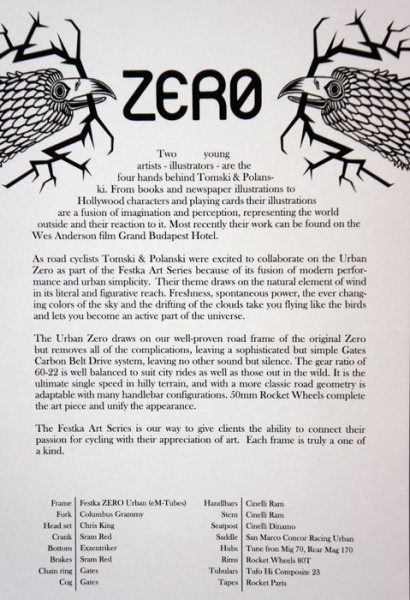

This Zero, which is their lugged carbon fiber frameset, is the first one from their Art Collection. The base color is white, and every other bit of color, including the blue underlying tone, was painted by hand. It took seven days. This one gets stainless dropouts and an eccentric BB so it can run a Gates Belt Drive. Only four will be done with each Art Collection paint scheme, but they can be ordered in any frame style you want.

Closeups of this, plus steel, ti and more carbon bikes (and wheels!) below…

The Zero was their crowd funded road bike launched in late 2012. It succeeded, and now it’s a staple of their collection.

The detail work was amazing on this bike, covered from head to toe in hand painted beauty.

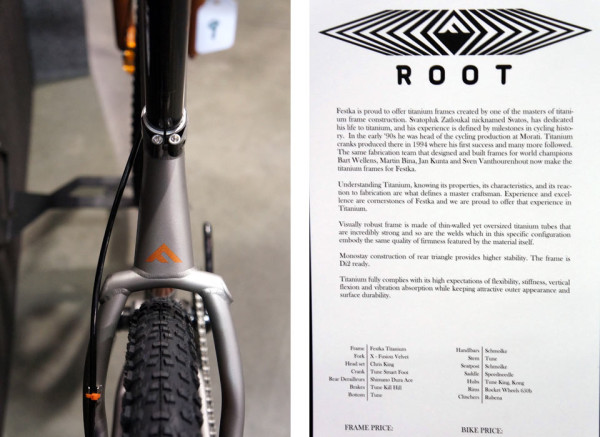

New titanium frame is the highlight. It’s more than a year and a half in development, planning and fabrication. It’s a globally sourced bike, with tubes from the US, Czech Republic and elsewhere.

We focused on the ‘cross bike (shown below) in the preview, but they also took the titanium to their mountain bikes. The chainstays use a unique design to create space and helps disperse the welds across more surface area.

The dropout design helps diffuse vibrations from braking. The chainstay yoke allows plenty of room for any size double chainring, but runs perfectly well as a 1x.

The seatstays lead to a monostay that’s tapered from a huge interface at the seat tube to a wider cross section at the yoke. That lets them keep it laterally stiff. They can make it in any wheel size you want.

Tubes are heavily shaped, with ovalization and butting specific to each size frame, which they say maximizes the benefits of ti’s inherent comfort but providing stiffness where needed for proper power transfer.

Average frame weight target is around 1,500g, but that depends on BB and headtube spec and rider wishes.

Pretty.

This Union Jack frame use welded Columbus XCr steel tubing with their new disc-specific dropouts. They reworked the rear end to handle the different stresses disc brakes put on the frame, then gave it a heck of a polished-with-paint graphics package.

They also built XCr tubes with stainless steel lugs, as shown on this customer’s standard road bike.

Little details include the GPS coordinates of the owner’s birthplace and other personal cues hidden around the frame.

The Daredevil is a track bike, this one with an Evel Knievel inspired paint scheme in the Czech Republic colors.

Festka’s Chrome coating is an up-to-a-month long process of chrome activation with salt fusion, flaming and careful finishing before a final lacquer coat is applied. They added a small hit of black to the top coat to give it a smoky finish. Think this is bright? Check out their track bike from last year’s show and the steel road bike they showed separately.

As if the variety of frame materials and paint options weren’t enough, they’re starting to make wheels in house, too under the Rocket Wheels brand. Production begins with the solid disc rear track wheel shown here. Eventually, they’ll produce standard carbon rims in house, too. They’re also working toward producing custom track and triathlon disc wheels based on rider size and style. For a smaller rider, they can make one as light as 700g. Price on the custom ones is around $2,000, and they’ll have Tune hub internals. They can be done with 19mm or 22mm wide rim beds, tubular only.

Look for more at RocketWheels.cc, coming soon.