Magura loves Sedona. Believe it or not, this was the 10th year in a row that Magura USA has held their US press camp among the towering red rocks of Sedona. It seems fitting that this would be their 10th camp as the milestone marked what we see as Magura really getting back to the forefront of braking.

Using the opportunity to introduce their new MT NEXT brake line, Magura has been working hard over the past two years to develop the perfect blend of power, modulation, and heat management. In the past few years Magura’s brakes have been good, but pale in comparison to their latest offerings.

First impressions, tech, and more after the break…

Appropriately called the MT NEXT, the latest brakes from Magura are an evolution of their MT brake line. As one of the pioneers of mountain bike hydraulic brakes in 1987, Magura has a long history of hydraulics engineering. Even with that braking pedigree though, Magura faces stiff competition from brake giants like Shimano, so the company needed a new brake that checked all of the boxes. They needed to be light, powerful, have impressive modulation, and offer modern brake performance across the board.

If first impressions are any indication, Magura nailed it with the most complete line of brakes we’ve seen from the German company.

A large part of the redesign is the addition of a new 4 piston caliper. Basically just a miniaturized version of their winning supermoto/superbike brake caliper, the tri-arch one piece design offers incredible power and stiffness. NEXT brakes will be split into two categories, the dual piston even numbered MT2, 4, 6, and 8, and the new MAG-Performance line with the quad piston MT5 and 7 brakes.

Both calipers are one piece designs with Magura’s Duraplastic pistons. The dual piston calipers have been revised slightly for better heat dissipation and power, but retain the use of their 22mm pistons. On the 4 piston brakes, the pistons have been downgraded to 17mm with individual brake pads. Technically the MT7 has 4 individual brake pads, while the MT5 has individual brake pad material pods on one backing plate for each side of the rotor. This allows for a cooling gap between the front and the rear pad on each side of the brake for better performance and braking consistency.

Each caliper continues the use of Magura’s MagnetIXchange brake pad system which uses high powered magnets embedded in each piston to hold the pad in place.

Inevitably when talking about Magura brakes, there is usually someone who chimes in on the comment section with disparaging remarks about “plastic” master cylinders. As Magura engineer and project manager Stephan Pahl will tell you – they are not basic plastic, but a complex mixture of injection molded carbon fibers in a thermoplastic matrix. Given the name of Carbotecture, there are technically two levels with Carbotecture and new Carbotecture SL. The new SL version is full carbon and uses longer carbon strands for improved strength and reduced weight.

Why Carbotecture? Magura states that by creating such lightweight levers, they can focus the weight on the calipers where it really matters for braking performance and heat dissipation. Officially, Magura says the levers account for 20% of the total system weight, compared to 80% for the caliper, rotor, and hose. Carbotecture also allows for levers with an extremely high impact resistance while remaining lighter than an aluminum lever body. Magura goes as far as claiming that Carbotecture components have the highest flexural fatigue strength of all conventional bike component materials. That means when your bike falls out of the shuttle vehicle, the aluminum brake lever might break off, but the Carbotecture body will be good to go (as Magura once found out first hand). If you’re still concerned about the durability of Carbotecture components, just know that BMW is now specing full Carbotecture brake and clutch assemblies on their motorcycles which will be going much faster than you.

A lot of the design of the brake lever has been engineered with service in mind – it will always be easier to replace external parts rather than the lever body itself. That is precisely the reason why the previous MT EBT (easy bleed technology) screw was so easy to strip out. Magura wanted the screw to strip out before the lever body did. With that said, they have improved the EBT screw for the NEXT series and the screw now features a deeper head for better tool purchase. Now instead of stripping out, if you over-torque the EBT screw the head will snap off, again saving the lever body. Even though the head will be gone, Magura says there will still be enough purchase to remove the broken EBT screw and replace it. As an added bonus, new EBT screws are backwards compatible to the original MT line.

Inside the brake you will find a new machined alloy brake piston as well as nearly double the amount of mineral oil as before. Both of these will help to maintain performance as the heat builds, though Magura says they prefer to keep as much heat as possible in the rotor where is is more easily dissipated.

An additional benefit of Carbotecture technology is the ability for perfect piston bore finishes without any additional machining. However, Stephan points out that injection molding the lever bodies isn’t as easy as it sounds. As the parts cool, they shrink which means parts of the body with different wall thickness will shrink at different rates. This is part of the magic of Magura’s Carbotecture engineering as the molds don’t feature perfectly round bores, but rather are molded so the pieces shrink to the exact dimensions.

Side by side, the Carbotecture SL (left) and Carbotecture (right) bodies show some slight differences. Due to the increased strength of the SL material, walls can be thinner and holes can even be made where the Carbotecture body is solid. The SL bodies also have a different look with the carbon fibers catching the light in the sun. The largest hole on the SL body is for the BAT adjuster (silver knob in above photo) which actually moves the piston in the bore which changes the bite point.

Additionally, the lever’s pivot point has been moved 20mm closer to the handlebars which provides better ergonomics and a more linear lever stroke for better control.

In addition to the differences at the body, brakes will also feature different levers with the standard aluminum lever found on the MT 2, 4, 5, 6, and 7, and the super light Carbolay full carbon brake lever found on the MT8.

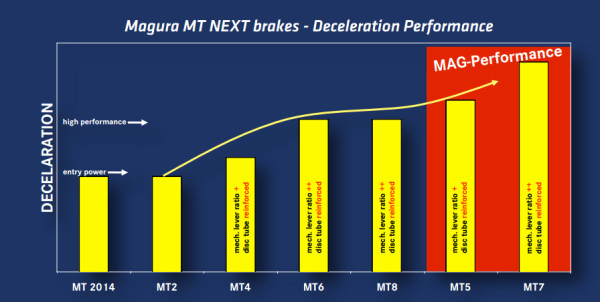

Just what do all these new features mean in terms of performance? An interesting departure from the previous MT series, is that the MT Next brakes are not built with the same power. While the first MTs all produced the same amount of stopping power, MT Next starts off with the lowest MT2 which offers the same power as every previous MT brake, and it goes up from there. Brake performance increases steadily until you get to the MAG-Performance line which includes the new four piston MT5 and MT7 brakes.

That means that the $100 per wheel MT2 has the same power as the old MT8, while the rest of the line offers drastically improved deceleration performance up to the incredibly powerful MT7.

Magura is continuing with the Storm and Storm SL rotors which are essentially the same shape with the SL offering more holes for a lighter rotor. Because the SL rotors have less thermal mass than the Storms, they are not as heat resistant but still offer excellent performance. All Magura rotors measure 2.0mm in thickness to ensure their durability.

To go along with the Storm rotors, all MT Next brakes will be equipped with organic pads. Sintered pads are currently not an option.

MT NEXT brakes will be available starting in June, 2014 from $100-370.

First Impressions:

While I wish we could have stayed in Sedona much longer, two days of riding in perfect weather conditions were a good chance to get an initial impression of the MT8 and MT7. If you haven’t been, Sedona is a desert paradise with incredible trails which range from tame to super tech. While the trails don’t offer much in the way of sustained high speed downhills, they make up for it in loose, technical, exposure laden routes where you definitely need your brakes to work.

On day one I found myself riding a Specialized S-Works Stumpjumper fitted with the MT7 quad piston brakes, followed by a day on the first ever Pivot Mach 6 out of the mold, which was running the dual piston MT8s. Thanks to the tool-less reach adjust found on both brakes, set up was fairly easy and I was able to get the brake levers fairly close to the bar. Technically a two finger brake lever, you can push the brakes inboard if you prefer to use a one finger approach which is how I chose to run them.

Perhaps the biggest standout for the new brakes is the incredible modulation. Many manufacturers claim to offer plenty of modulation, but nearly every other brake falls short compared to the new MT8 and MT7. The key though, is that the modulation doesn’t come at the expense of power. Not that locking up a brake will help you stop any quicker, but both brakes can easily be locked up if you try and with very little hand force at the lever. However, on the trail the modulation meant much more of the power was useable before the tires lost traction and started to skid. This proved to be very important on trails covered in sand and dust.

There was no doubt that the 4 piston MT7 brakes offered more power than the MT8s, but the power of the MT8s is quite a bit better than the previous version. If your rides consist of XC/Trail/AM type trails, than the MT8 series will offer plenty of stopping power with the MT7 series seeming better equipped for bigger, more aggressive riders on bigger bikes – which is why they are marketed towards enduro and DH.

Overall, the two brakes were nothing short of impressive. Magura might have lost some market share in the past few years, the but the MT NEXT line is proof that Magura is back.