Fairwheels bikes has designated 2014 as the year of testing. As a retailer, importer, and builder of some incredibly light components and bikes, the crew at Fairwheel has access to some of the lightest parts in the world as well as most expensive. Wanting to add more to the conversation than just building amazing bikes, Fairwheel has started a series of tests independent of any component manufacturers.

After starting with rims and then stems, Fairwheel has turned their attention to road handlebars, specifically, carbon handle bars. Ever wondered about the stiffness of those pricey top level bars? Fairwheel has the answers, after the jump…

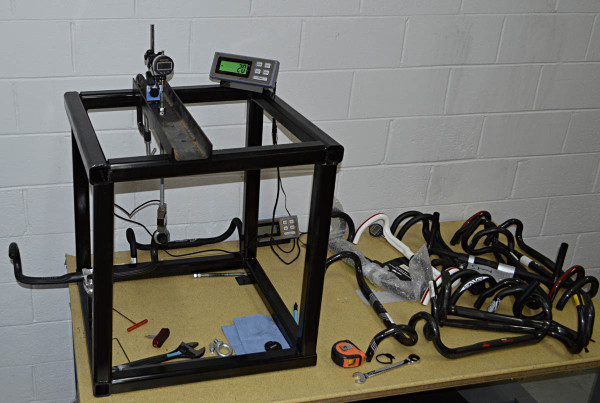

In order to make the testing as credible as possible, Fairwheel is once again working with Jason Krantz, mechanical engineer that not only has a ton of bike industry experience, but whose graduate involved composite materials and FEA. Using the same testing fixture as the stem test but modified to test handlebars, 16 bars were rounded up all as close to 44mm width as possible.

After securing each bar in the same Thomson stem (as short and stout as possible), each bar was preloaded with 20 pounds of force in the drops. From there, an additional 50 pounds of force was added to simulate the force of a strong sprinter pulling or pushing on the bar. Fairwheel then used these numbers to come up with the stiffness to weight ratio of each bar.

Read on for Fairwheel’s report on the testing, or head over to their blog to read more!

The following is from Fairwheel bikes:

Fair Wheel 2014 Road Handlebar Review

We’ve designated 2014 as the year of testing here at Fair Wheel. This is the 3rd test in the series, road handlebars. The first test which was stems can be found here: and the 2nd one on brakes can be found here:

We’ve once again brought back our favorite engineer, Jason Krantz. Jason’s a mechanical engineer whose graduate work focused on the intersection of composite materials and finite element analysis. Jason has worked for several companies in the bicycle industry and never fails to amaze us with the depth of his cycling related knowledge. He adds real value to all of the tests we perform.

Disclaimer: A lot of typing and numbers have gone into this article and we apologize in advance for any typos, but would warn that the possibility of mistakes is present.

Why do deflection testing on bars? We don’t believe that there is any efficiency to be gained through a stiffer handlebar, so why test for that? Losses in efficiency are minimal but a stiff handlebar and stem can make the bike feel especially responsive to rider inputs, especially out of the saddle. We’re unconvinced of any performance benefit to a stiffer bar, but many people like the feeling one provides. What we are convinced of is that the additive effect of parts that deflect more does at some point become a problem. The point at which it becomes a problem is different for different riders and terrains. Conversely, a flattened bar like the new 3T Aeronova or Enve SES models will provide increased deflection (and therefore bump comfort) compared to a bar with a round cross-section.

If you combined a very flexible, frame, steerer, stem, bar etc… into one bike you’d more than likely notice a lack of confidence in its handling. If you mounted the most rigid pieces you could find in one bike many people would find a lack of comfort. The ideal is some moving sweet spot in between that is different for each given set of circumstances.

About the testing method. Each handlebar was mounted in the fixture and the testing performed 3 times and then averaged. All bars tested were as close to 44 cm as could be. Each bar was mounted with recommend torque specs and preloaded with 20 pounds of force applied in the drops. Once preloaded the equipment was zeroed and another 50 pounds of force was added and a measurement recorded. The measurement was taken at the point of load

Notes about the loads tested: The actual load doesn’t matter because the response of the structure is linear. That is, a handlebar that deflects 5mm under a 25-lb load will deflect 7.5 mm under a 75-lb load, 10 mm under a 100-lb load and so forth. This assumption of a linear response to loads is valid roughly until an aluminum bar bends permanently (plastic deformation) or until a carbon bar breaks (brittle failure). These bars were loaded with 50 pounds because it’s a nice round number and a fairly realistic approximation of real-world conditions.

If a sprinting rider is pushing on the left pedal with 200 lbf (in other words, he can squat 400 lbs), he must create an equal and opposite moment (twisting force) via the handlebars. The pedal is about half as far from the frame centerline as the handlebar drops are, so it would take a reaction force of 100 lbs at the right-hand bar to counteract the pedaling force. This is the same as applying 50 lbf up on the one side of the bar and 50 lbf down on the other; the total moment is the same.

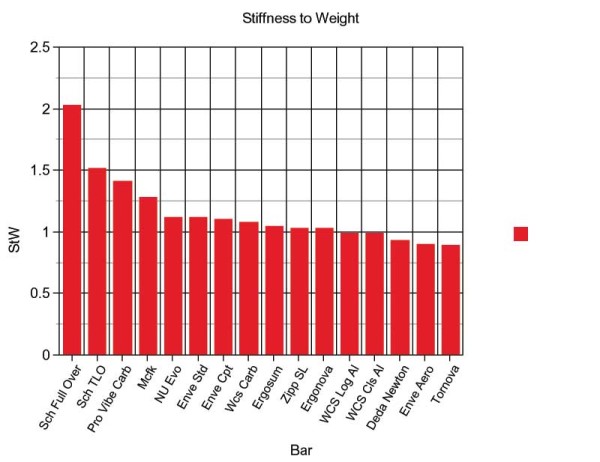

Stiffness to weight ratio: This was calculated using =((1/avg. defl) / weight) * 1000

Notes about bar width: Widths were recorded at the curve where levers would mount and were measured center to center.

Notes about reach, drop and flare: One thing that has always bothered us is that there is no standard system for measuring reach and drop. Actual vs. claimed reach particularly can vary dramatically, in this test alone the bars range by almost 3 cm in length. 3cm can be the difference between needing a 9 cm or 12 cm stem, yet many people don’t consider reach on their bars when making a choice. We decided to level the field here by measuring them all to the same standard. With the drops horizontal to the ground the reach is measured from the center of the top (where the bar mounts into the stem) to the leading edge of the vertical drop (where the lever would mount). Drop is measured with the drops horizontal to the ground and from center to center. For some companies our measurements may match up with what is claimed, but for others it may differ significantly because the manufacturer used a different measurement method.

We have a separate listing for flare. Flare is how much wider a bar is at the drops than where the levers mount. For some bars the widths in the locations are the same, but for others they may be as much as 4 cm wider at the end of the drops.

Carbon Fiber vs. Aluminum: – While carbon offers little or no weight savings when applied to stems, the lightest handlebars are usually made from laminated fiber. Handlebars are stressed primarily in bending, and 0-degree carbon fibers take these loads very, very well. When you throw in a few layers at 45 degrees to deal with torsional loads and maybe some circumferential reinforcements where the levers mount, you often end up with a bar that’s a bit lighter than the equivalent aluminum bar.

As noted above, aluminum bars tend to fail by bending permanently (ductile failure) while carbon bars usually snap into pieces (brittle failure). While “shattered” carbon bars make for shudder-inducing post-crash photos, keep in mind that a strong carbon bar will shrug off loads that would bend its aluminum counterpart. Ductile failure is not necessarily a better failure mode than brittle failure.

Reduced weight is a wonderful thing, but carbon bars offer another advantage: they tend to damp high-frequency vibration better than aluminum bars. Composite structures generally damp vibration better than metallic ones, and many riders have found real-world damping benefits when they fit a carbon handlebar. It would be interesting to quantify carbon bar damping; one way to do so would be to wire an accelerometer to the drops and then gently strike or pluck the bar, letting it “ring” at its natural frequency. One could then read the accelerometer data to see how quickly the vibrations dissipated. This ring-down test may be on the Fairwheel menu for a future article, but is outside the scope of this test.

Opinions on the bars: Most bars are obviously similar in concept, but still very different in execution. Finding a bar that is comfortable to a rider involves personal preference as to the shape and depth of the drop as well as reach, flare and sweep. Because of this we’re going to keep our opinions on fit and shape to a minimum, leaving those up to each individual to find what is right for them. We’ll focus this review on weight, stiffness, reach, finish, price etc…

Testing results:

Make: 3T

Model: Ergonova

Width: 43 cm

Flare: 1.5 cm

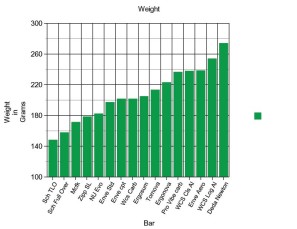

Weight: 223.2 gms

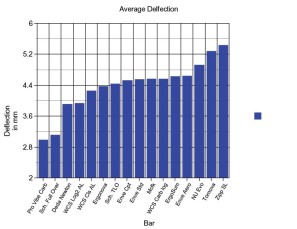

Avg Defl: 4.37 mm

StW: 1.03

Drop: 119 mm

Reach: 90 mm

Price: $325

Material: Carbon

Opinion: Overall a well balanced bar. Price, and reach fall in the middle of the field but weight and SxW are below the midpoint in the bottom half of the field. Deflection is better than average being 6th out of 16. Nicely finished with multiple graphic options including the ever popular black on black stealth.

———————————————–

Make: 3T

Model: Ergosum

Width: 44 cm

Flare: 1.5 cm

Weight: 205.1 gms

Avg Defl: 4.62 mm

StW: 1.05

Drop: 126 mm

Reach: 103 mm

Price: $325

Material: Carbon

Opinion: Like the ErgoNova the ErgoSum is also nicely finished, decently priced and includes the same graphic options. The ErgoSum though is a longer reach bar, being 3rd from the longest in the test. It’s also lighter than the Ergonova which gives it a better stiffness to weight ratio, 9th out of 16.

———————————————–

Make: 3T

Model: Aeronova Team

Width: 44cm

Flare: 1 cm

Weight: 213.3gms

Avg Defl: 5.28mm

StW: 0.89

Drop: 138mm

Reach: 94mm

Price: $325

Material: Carbon

Opinion: The Aeronova is a flat topped bar that fills the reach/drop gap between the ErgoNova and ErgoSum. However the flat top comes at a price either weight or deflection. The Aeronova is the lightest fully flat topped bar in the test, however that causes it to be 2nd from the bottom in terms of deflection. Like the other 3T bars this one too is very nicely finished with a pretty neutral shape in terms of reach and drop and is also available in several finishes.

———————————————

Make: Deda

Model: Newton Deep

Width: 44cm

Flare: 0cm

Weight: 274.4 gms

Avg Defl: 3.90mm

StW: 0.93

Drop: 137mm

Reach: 106mm

Price: $150

Material: aluminum

Opinion: The Deda is one of only 3 alloy bars in the test. This too has its pros and cons. Being alloy it naturally is less expensive than carbon offerings, but also heavier. The Newton is a very classic style bar with long reach (longest measured in the test) and fairly deep drops. The Newton is also the heaviest bar in the test, but this extra weight gives it one of the best deflection results in the test rating 3rd in deflection. However this extra stiffness isn’t enough to overcome the weight penalty which puts it 3rd from the bottom in terms of stiffness to weight.

———————————————–

Make: Enve

Model: Aero

Width: 40cm

Flare: 44cm

Weight: 239.0gms

Avg Defl: 4.64mm

StW: 0.90

Drop: 121mm

Reach: 85mm

Price: $400

Material: Carbon

Opinion: The Enve SES Aero is one of only 2 fully flat topped bars in the test (3T Aeronova being the other) Enve chose to add some weight to the bar to help keep it from deflecting as much so it is heavier than the Aeronova but also stiffer with a slightly better stiffness to weight ratio. Since this bar is intended to be aero, Enve opted to flare it significantly, 4cm to be exact, which is 2.5 cm more flare than any other bar in the test. This actually separates it quite well from most of the bars giving it a very narrow profile while on the hoods and still plenty of width when in the drops. The bar is very nicely finished and is the only Enve bar available in the popular black on black combo and at 85mm reach is the shortest reach of the 3 Enve bars.

———————————————–

Make: Enve

Model: Compact

Width: 44cm

Flare: 1.5cm

Weight: 202.1gms

Avg Defl: 4.52mm

StW: 1.09

Drop: 121mm

Reach: 88mm

Price: $350

Material: Carbon

Opinion: The Enve compact is without a doubt a super well balanced bar. In testing 16 bars, this compact finished 7th in both overall weight and stiffness to weight, as well as 8th in average deflection making it probably the most well balanced bar in the test. Being the compact version puts the bar in the shorter end of the reach spectrum with only 4 bars having shorter reach and 3 bars with shallower drops. The $350 price puts it just slightly above some of the other carbon bars in the test, but still well off the most expensive ones. To date this bar is still not available in black on black, which is one of the requests me often see.

———————————————–

Make: Enve

Model: Standard

Width: 44cm

Flare: 2cm

Weight: 197.4gms

Avg Defl: 4.55mm

StW: 1.11

Drop: 147mm

Reach: 96mm

Price: $350

Material: Carbon

Opinion: The Enve classic is similar to the Enve compact in most of its test results. 6th in weight, 8th in stiffness to weight and 9th in average deflection puts this bar just behind the compact in terms of being the bar that balances the traits most evenly. Which is why these two bars are probably some of the most popular that we’ve seen in this class. The Standard is basically the compact with a longer reach and deeper drop for those looking for a more classic fit in their bar. Like the compact the standard has great finish quality and looks.

———————————————–

Make: Mcfk

Model: Mcfk

Width: 43cm

Flare: 1.5cm

Weight: 171.8gms

Avg Defl: 4.56mm

StW: 1.28

Drop: 112mm

Reach: 77mm

Price: $550

Material: Carbon

Opinion: The Mcfk bar definitely stands out in several ways. Most noticeable is the short reach. At 77mm reach it’s almost a full cm shorter than the next shortest bar tested. This is partly achieved through a nicely back swept top. The drops also have a very distinct shape being perhaps the ergo-ist (if that could be a word) It’s also the shallowest drop of all the tested bars. Weight wise Mcfk did really well coming in 3rd lightest but still managing to hit 10th in deflection giving it the 4th best stiffness to weight ratio in the test. However the superlight weight and good S/W ratio come at a price, both monetarily (3rd most expensive) and in terms of a 100kg rider weight limit. However it’s hard to deny this as a top contender for the rider that likes a short reach and shallow drop light weight bar that still has plenty of stiffness.

———————————————–

Make: New Ultimate

Model: Evo

Width: 44cm

Flare: 0cm

Weight: 182.4gms

Avg Defl: 4.92mm

StW: 1.12

Drop: 126mm

Reach: 85mm

Price: $270

Material: Carbon

Opinion: The New Ultimate Evo slots into the test as the least expensive carbon bar tested. It has a very short reach tied for 2nd (with Enve SES Aero) and a very average 126 drop. The Evo has an ovalized top section, but certainly not a full flat top. In terms of weight it does very well coming in 5th overall but its deflection is 3rd from the bottom, due to the decision to ovalize the tops as well as keep the weight so low. However when looking at stiffness to weight ratios the light weight more than offsets the deflection putting the Evo into 5th overall in the category. It’s available in both nude carbon as well as white and both have a very nice finish to them but with an 88 kgs rider weight limit.

———————————————–

Make: Pro

Model: Vibe Carbon

Width: 43.5cm

Flare: 0cm

Weight: 236.5gms

Avg Defl: 2.99mm

StW: 1.41

Drop: 127mm

Reach: 91mm

Price: $370

Material: Carbon

Opinion: The Shimano Pro-Vibe carbon topped the test in terms of average deflection. It is significantly stiffer than all the other traditionally diametered bars in the test. Only the oversized Schmolke gave it a run for its money. However it seems that this stiffness is due mostly to added material since this bar also topped the test in another category, being the heaviest carbon bar in the test with traditional round or oval tops. The stiffness is enough that it overcomes the added weight putting this into the 3rd spot in terms of stiffness to weight ratio, but this bar is definitely catered more toward the sprinter or heavy rider who is more concerned about stiffness than weight. Reach and drop both hit very mid field and the finish on the bar is very nice.

———————————————–

Make: Ritchey

Model: WCS Carbon Logic2

Width: 44cm

Flare: 1cm

Weight: 202.2

Avg Defl: 4.57mm

StW: 1.08

Drop: 139mm

Reach: 94mm

Price: $300

Material: Carbon

Opinion: The Ritchey WCS Carbon Logic is also a bar that targets a balancing of characteristics. 8th in terms of weight, 11th in terms of deflection and mid field 8th in terms of stiffness to weight ratio. Pretty average reach with a deeper than average drop. Nicely finished and with a decent price.

———————————————–

Make: Ritchey

Model: WCS Classic

Width: 44cm

Flare: 0cm

Weight: 239.0gms

Avg Defl: 4.25mm

StW: 0.99

Drop: 133mm

Reach: 90mm

Price: $100

Material: Aluminum

Opinion: The Ritchey WCS Classic is exactly that, a classic shaped alloy bar. Along with another test alloy Ritchey the Classic is the least expensive bar in the test and is the lightest of the 3 tested alloy bars. It’s the least stiff of the 3 alloy bars, but with its lighter weight it is tied for 1st in stiffness to weight ratio of the alloys. Medium reach and deep drop.

———————————————-

Make: Ritchey

Model: WCS Logic2

Width: 44cm

Flare: 0cm

Weight: 254.2gms

Avg Defl: 3.94mm

StW: 0.99

Drop: 135mm

Reach: 93mm

Price: $100

Material: Aluminum

Opinion: The Logic2 is the 3rd alloy bar in the test and is very similar in test results to the Classic but with a longer reach and deeper drop. The 2nd heaviest bar in the test but also the 4th stiffest put this one into a shared spot with the WCS classic for best stiffness to weight ratio of the alloy bars.

———————————————–

Make: Schmolke

Model: TLO

Width: 44cm

Flare: 0cm

Weight: 148.4gms

Avg Defl: 4.43mm

StW: 1.52

Drop: 134mm

Reach: 102mm

Price: $640

Material: Carbon

Opinion: The Schmolke TLO is definitely a standout in the weight category and also the price category. We don’t think this weight should come as a surprise though considering that Schmolke produced the very first full carbon handlebar and has been focused on developing and refining that design for just about 25 years. The TLO really is the pinnacle of how light a carbon bar can be yet still be safe for most riders. Even at the lightest of all tested bars it still finished just better than mid field in terms of deflection being 7th out of 16. In terms of stiffness to weight it finished 2nd being bested by only a uniquely designed Schmolke bar. The stock TLO has a rider weight limit of 75-80kgs, but they will make bars especially for heavier riders. The TLO has a longer reach and deeper drop than most of the bars in the test.

———————————————–

Make: Schmolke

Model: Full Over

Width: 43cm

Flare: 0cm

Weight: 158.1gms

Avg Defl: 3.11mm

StW: 2.03

Drop: 133mm

Reach: 86mm

Price: $750

Material: Carbon

Opinion: The Schmolke Full Over is a bit of a different bar. Typically a bar is 31.8mm at the stem clamp and then tapers down to about 24mm. To keep weight down but increase stiffness you need to increase tube diameter. Assuming a constant wall thickness, increasing a tube’s diameter increases its weight directly with the diameter, but the stiffness of the tube increases with the cube of the diameter. The Full Over takes advantage of this principle, keeping a larger diameter, about 27mm, all the way to the end of the drops. This larger diameter makes a significant difference in stiffness. The Full Over was the 2nd lightest bar in the test and the 2nd stiffest. However it did so well in both of these that stiffness to weight ratio is almost 25% higher than the next bar (the TLO). Having a larger diameter bar means that standard lever clamps do not fit so the bar comes with its own carbon lever clamps, which increase the price yet again, but also knock another 5-10 grams off the total system weight.

———————————————–

Make: Zipp

Model: SL

Width: 44cm

Flare: 0cm

Weight: 178.4gms

Avg Defl: 5.45mm

StW: 1.03

Drop: 148mm

Reach: 102mm

Price: $300

Material: Carbon

Opinion: We should preface this by saying the Zipp bar we tested is not the latest model and newer models may test differently. We’ll include newer models in future tests. The Zipp SL is one of the lighter bars in the test, 4th overall in weight. Unfortunately it was the least stiff of all tested bars which drags down its stiffness to weight numbers making it 10th overall, just below mid field. It does however have a long reach and the deepest drops for those looking to have a more aggressive position on their bike.

———————————————–